Weight-coefficient-free double-motor driving system predictive torque control method

A dual-motor drive and torque prediction technology, which is applied in multiple motor speed/torque control, motor generator control, AC motor control, etc., can solve the problems of system loss increase, phase current distortion, and system zero-sequence current overshoot. Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

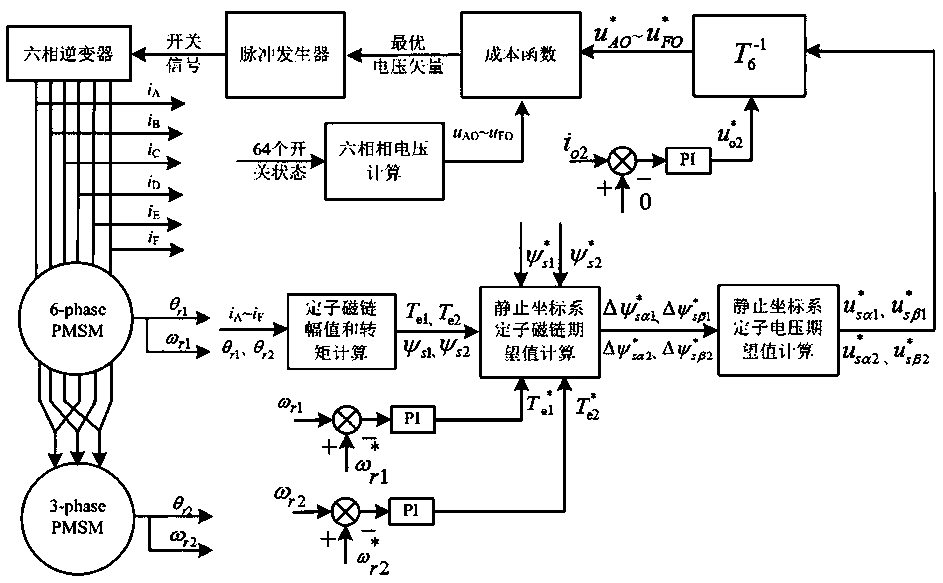

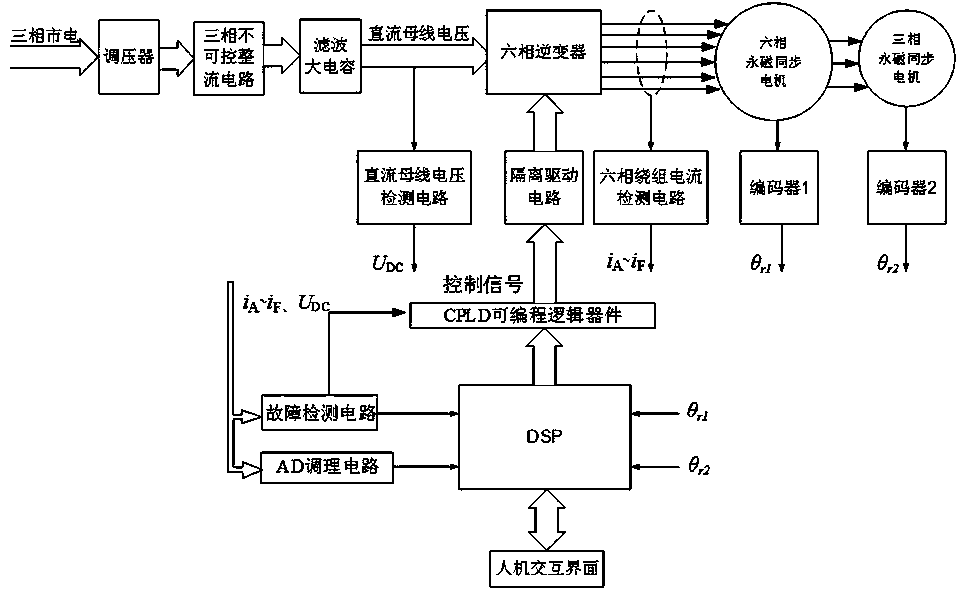

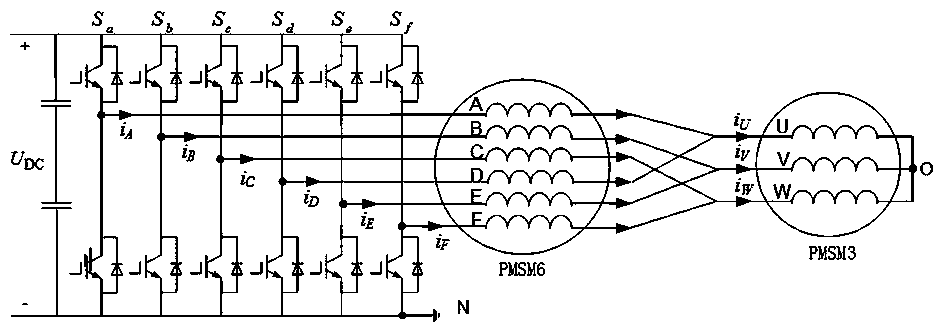

[0085] The invention proposes a predictive torque control method for a dual-motor drive system without weight coefficients. The purpose has three aspects: one is to realize the precise control of the torque and stator flux amplitude of the two PMSMs and the effective suppression of the zero-sequence current; the other is to eliminate the weight coefficient of the cost function in the predictive torque control algorithm; the third is to reduce the predicted torque. Calculation amount of the moment control algorithm. According to the six-phase current, DC bus voltage, position angle and other information obtained by system sampling, the expected voltage and zero-sequence voltage expected value of the two PMSMs in the static coordinate system are obtained through the PI regulator, and then through T 6 The inverse transformation of the matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com