Aluminum plate dust removal device convenient to disassemble and assemble and implementation method thereof

A dust removal device, a technology that is easy to disassemble and assemble, applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low dust removal efficiency, high work intensity, and thin magnetic sheets affecting the process, so as to improve dust removal efficiency and reduce labor costs. Excellent strength and dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

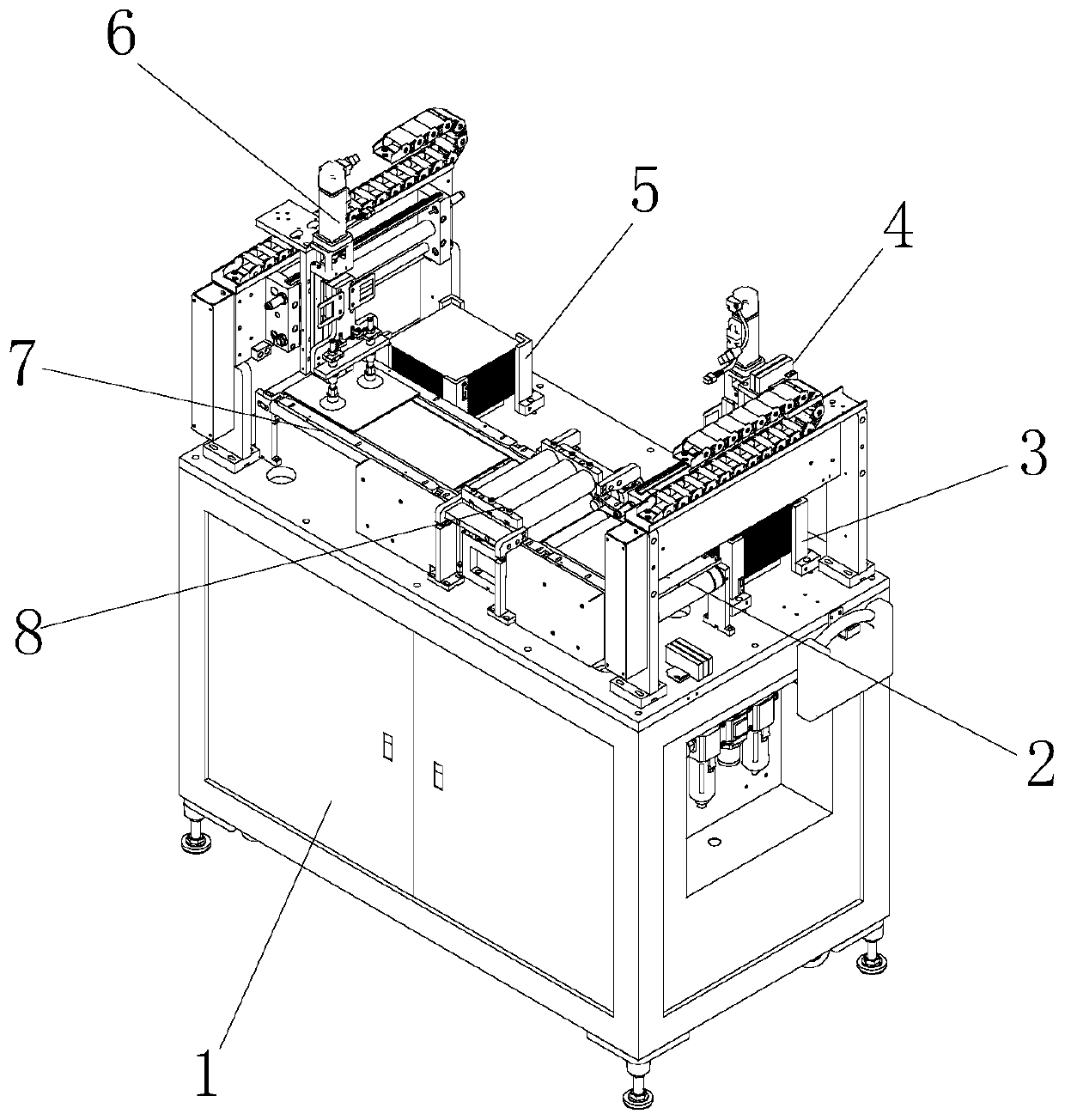

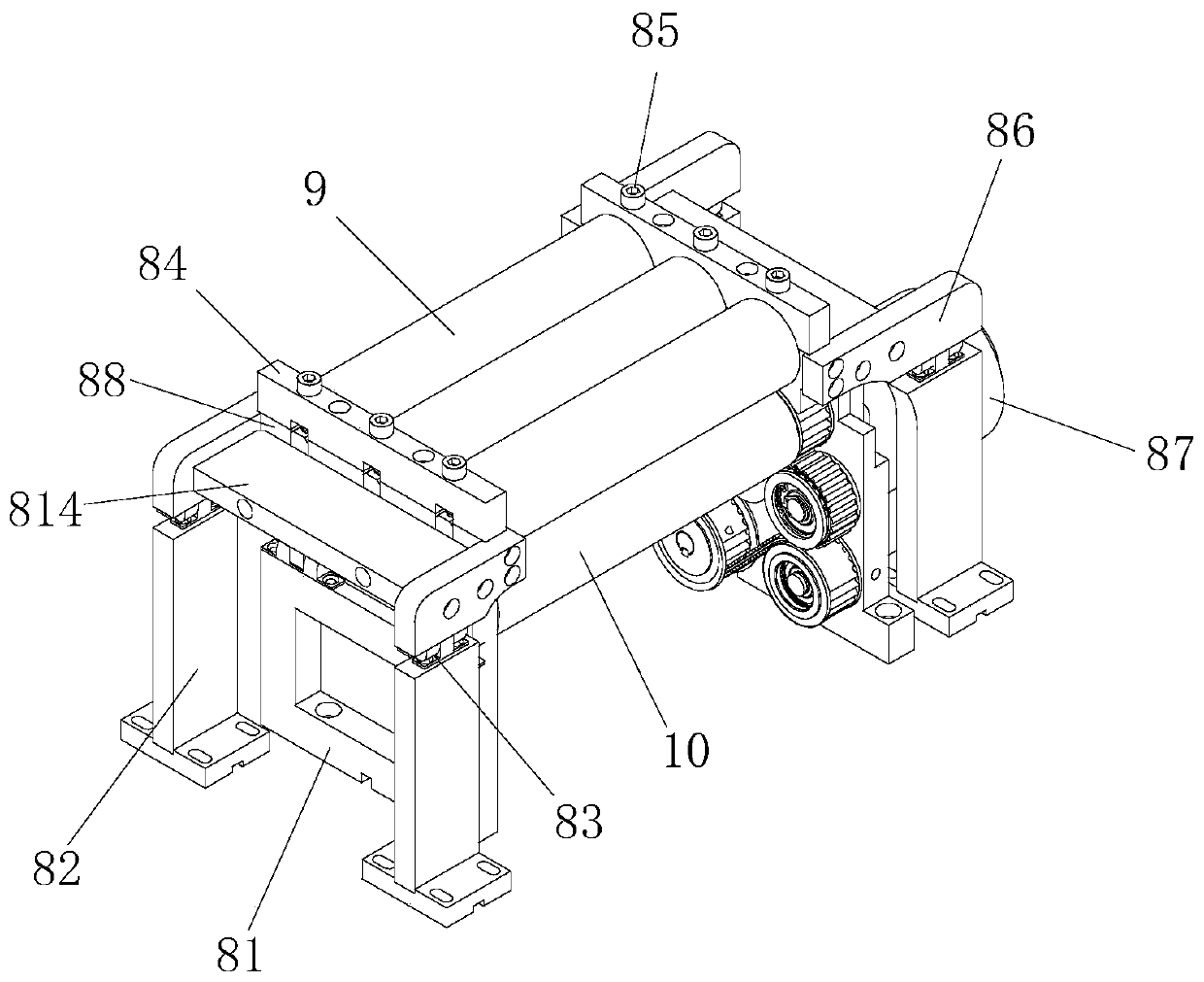

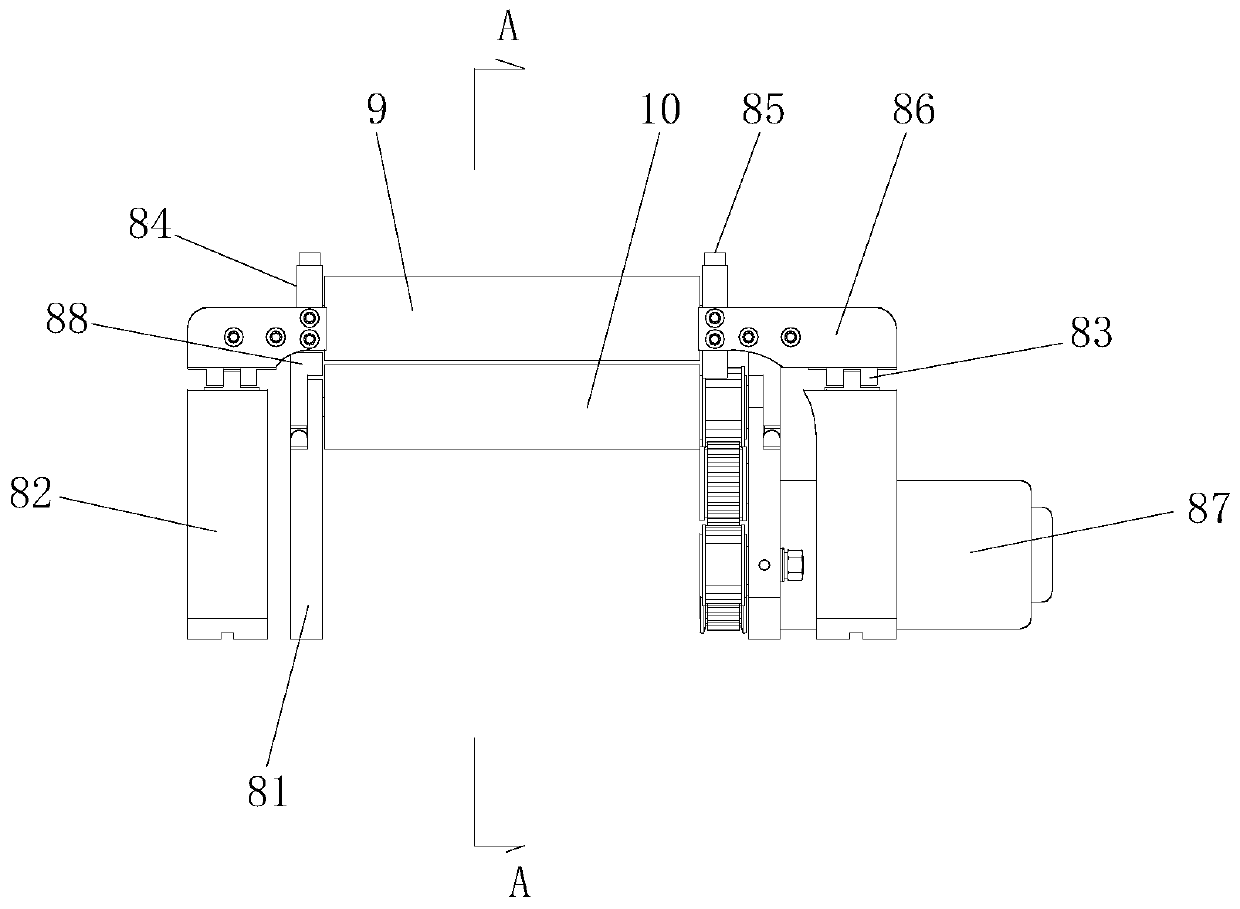

[0051] see Figure 1-13 , the present invention provides the following technical solutions: a convenient disassembly and assembly dust removal device for aluminum plates, including a frame 1, a dust removal mechanism 8 is connected to the middle position above the frame 1, and a feeding belt line 2 is respectively provided on both sides of the dust removal mechanism 8 And the feeding belt line 7, one side of the feeding belt line 2 is provided with a feeding bin 3, the top of the feeding belt line 2 and the feeding bin 3 is provided with a feeding mechanism 4, and one side of the feeding belt line 7 The side is provided with the feeding bin 5, and the upper side of the feeding bin 5 and the feeding belt line 7 is provided with the feeding mechanism 6, and the dust removal mechanism 8 includes three detachable dust removal driven roller bodies 9 arranged side by side and three Two detachable dust removal driving roller bodies 10 arranged side by side, three dust removal driven ...

Embodiment 2

[0073] This embodiment differs from Embodiment 1 in that: specifically, a spring 815 is sleeved on the screw 85, and the spring 815 is located between the upper cover plate 84 and the lifting shaft 91

[0074] By adopting the above technical scheme, when the alumina plate passes through the middle of the three dust removal active roller bodies 10 and the three dust removal driven roller bodies 9, the three dust removal driven roller bodies 9 can float upward for a short distance, so that the cooperation becomes flexible, At the same time, the spring 815 can also ensure that the positive pressure between the alumina plate and the dust removal roller is large enough, and the dust removal effect is better.

[0075] The FRS-410 type optical fiber sensor of RIKO is used for detecting whether the product optical fiber 24 among the present invention is selected; The FRS-410 type optical fiber sensor of RIKO is selected for use in detecting the empty material optical fiber 34; Module ...

Embodiment 3

[0077] The difference between this embodiment and Embodiment 1 is that a vacuum pressure switch is installed on the lifting plate 46 to detect the vacuum degree. If the displayed value exceeds the set value, it means that the aluminum oxide plate is not sucked up, and the vacuum pressure switch will send a signal to the controller, so that The device suspends operation and gives an alarm to remind the operator to troubleshoot the equipment.

[0078] Further, the realization method of the convenient disassembly and assembly aluminum plate dust removal device according to the present invention includes the following steps:

[0079] (1), the operator puts the alumina plate to be dedusted into the feeding bin 3;

[0080] (2), the rodless cylinder 410 action on the feeding mechanism 4 drives the lifting module 45 to move to the top of the feeding bin 3, the lifting servo motor 44 drives the slider of the lifting module 45 to move downward, and the vacuum suction cup 48 The solenoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com