A kind of alloy easy-open lid forming method

A forming method and technology of easy-open lids, which are applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as difficulty in fixing tinplate of various sizes and specifications, failure of cover blocking devices, and jamming of arch covers, etc., so as to reduce Plate scratches, avoid elastic failure, reduce the effect of excessive movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

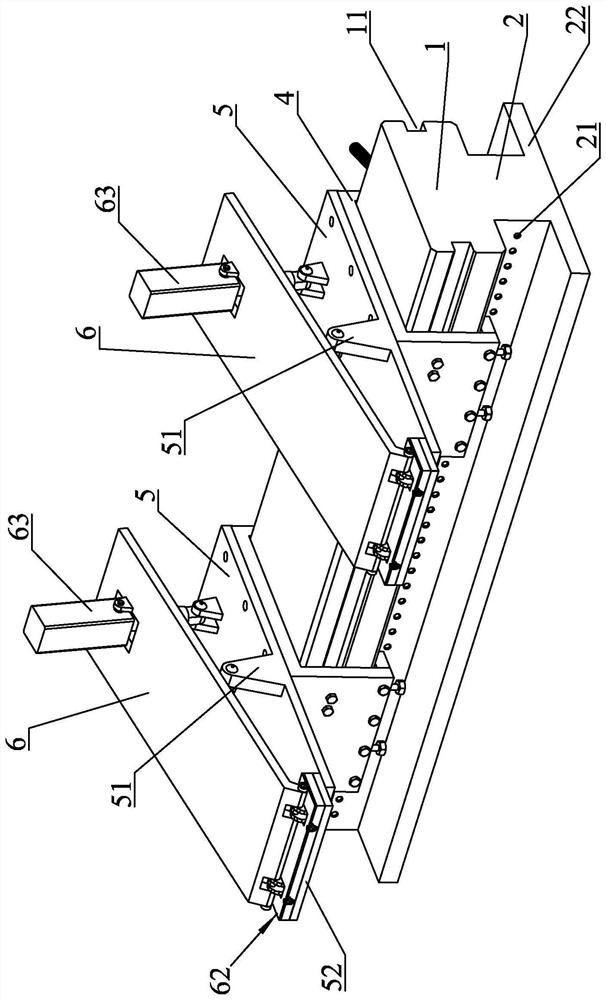

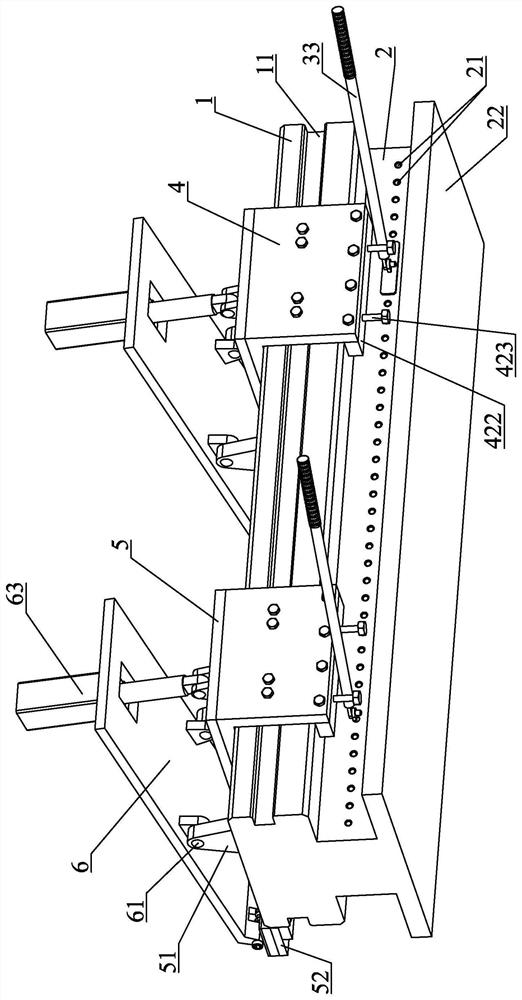

[0052] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

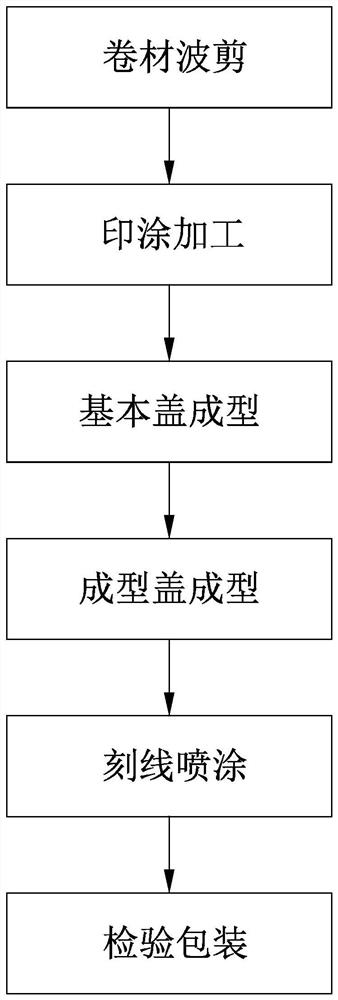

[0053] like Figure 1 to Figure 16 As shown, it is a method for forming an alloy easy-to-open lid according to the present invention, which includes the following steps:

[0054] ① Coil wave shear: Cut the tinplate coil to form a wave shape, and then cut off the edge material from the wave-shaped sheet; ② Printing and coating processing: Coat the inner and outer surfaces of the sheet, and then dry it; ③ Basic cover forming: use the plate fixing device to fix the plate and punch the plate to form the cover blank; first preform the countersunk ribs on the edge of the cover blank, and then roll the edge of the cover blank inward to form a sealing groove; Glue the sealing edge, and then dry to form the basic cover; use the cover collecting device to collect the basic cover into a cylindrical shape; (4) Forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com