Full-liquid-crystal instrument panel for automobile and manufacturing method thereof

A manufacturing method and instrument panel technology, applied in applications, household components, household appliances, etc., can solve problems such as poor sealing performance, time-consuming and labor-intensive, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

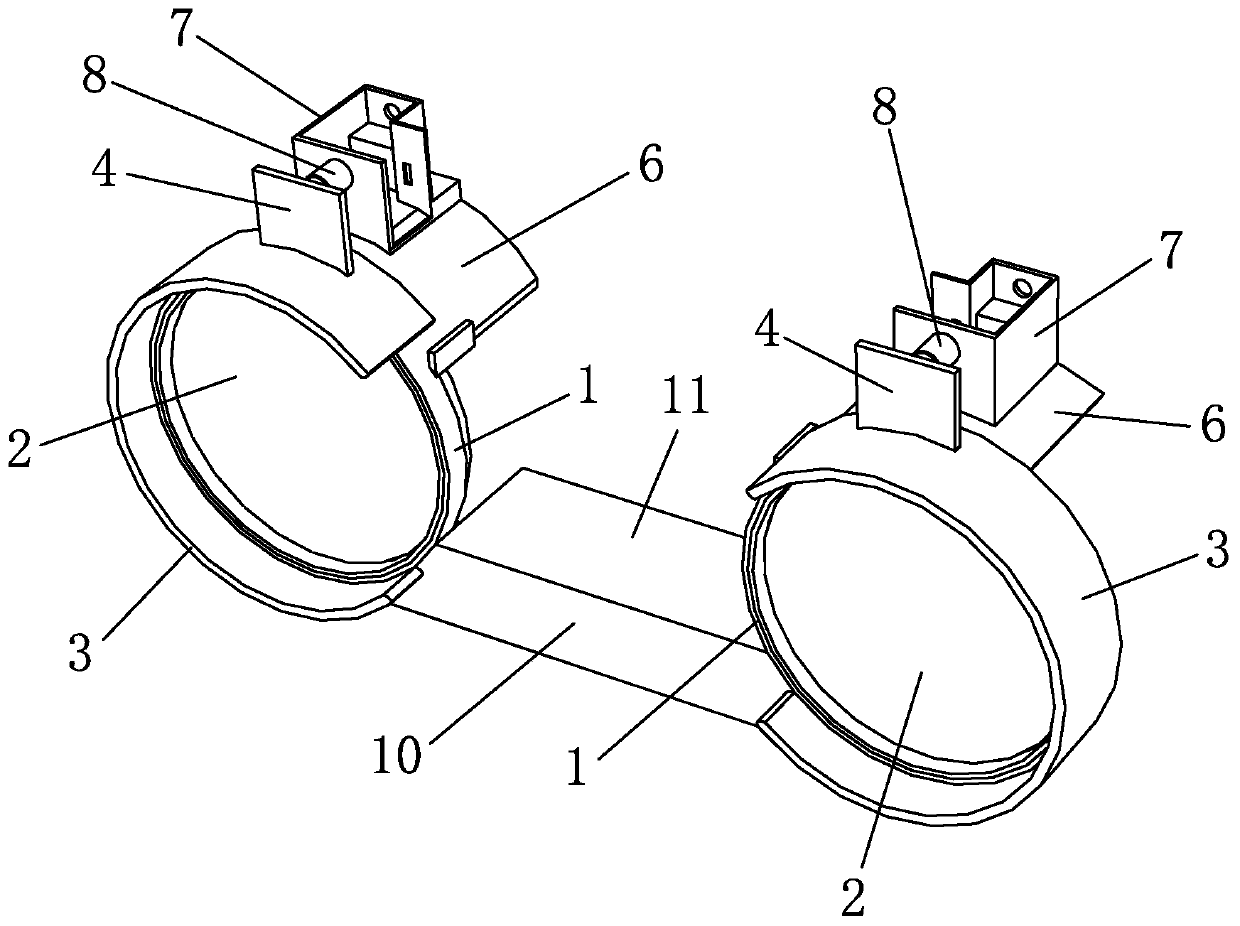

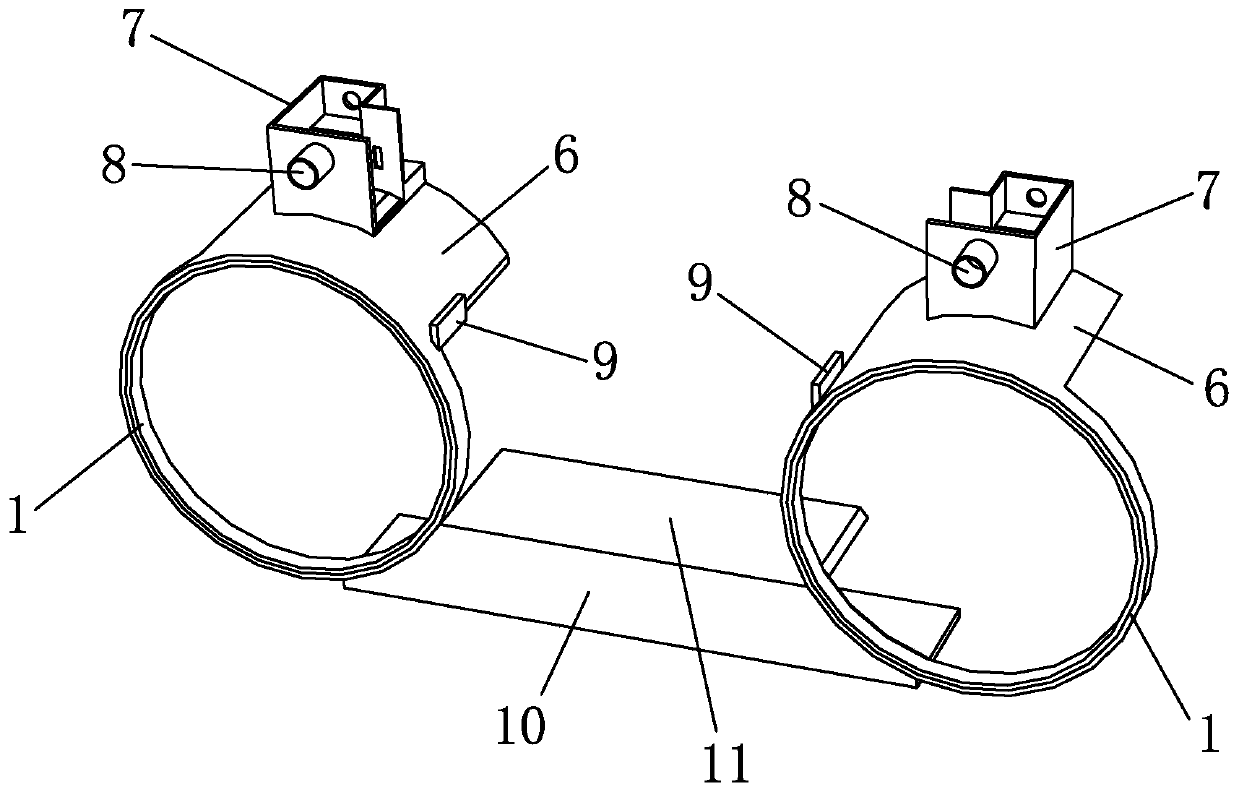

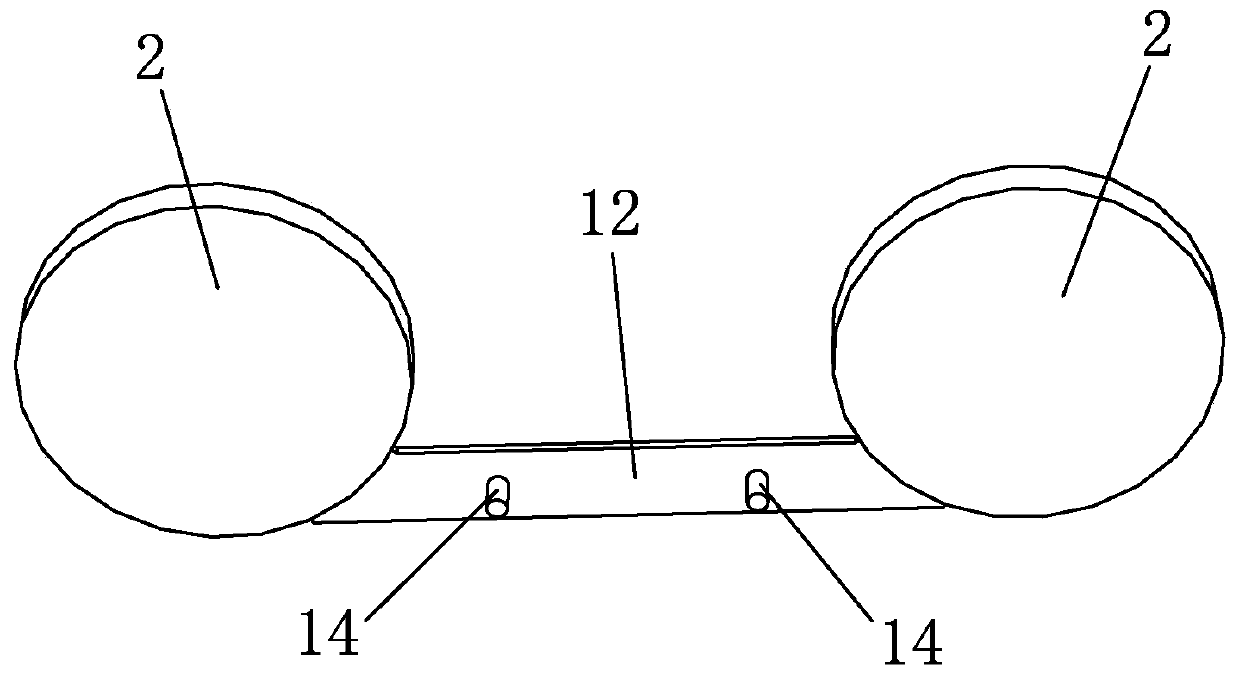

[0052] Such as Figure 1 to Figure 5 As shown, it is a full liquid crystal instrument panel for automobiles according to the present invention, which includes a frame 1 and a display screen 2, the display screen 2 is embedded in the frame 1, and the display screen 2 adopts a liquid crystal display screen.

[0053] The present invention also includes a protective cover 3, which is made of metal, and the protective cover 3 is wrapped on the outside of the frame 1. The outer surface of the protective cover 3 is provided with a positioning plate 4, the side of the positioning plate 4 is provided with a first positioning column 5, the frame 1 is provided with an extension plate 6, and the side of the extension plate 6 is provided with a limit protrusion 9, which is necessary for the entire liquid crystal instrument. The plate performs the limiting function. The outer surface of the extension plate 6 is provided with a limit seat 7, and the limit seat 7 is used for the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com