Screening device capable of automatically identifying forward and reverse directions of products

A screening device and automatic identification technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reduced production efficiency, high robot and vision input costs, increased labor intensity, etc., to achieve low manufacturing costs and reliable screening functions , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A screening method for automatic identification of product forward and reverse screening devices, the steps are as follows:

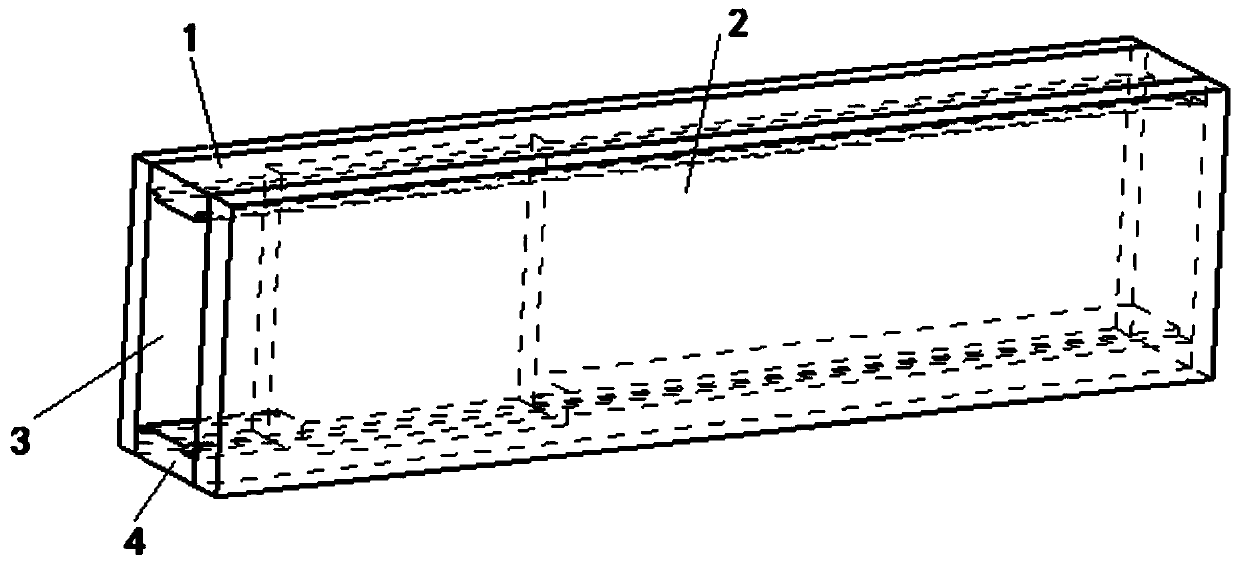

[0028] The first step: install the automatic identification product positive and negative screening device on the upper end of the hoist and at the entrance of the pipeline, so that the screening hole of the screening orifice plate 3 is downward;

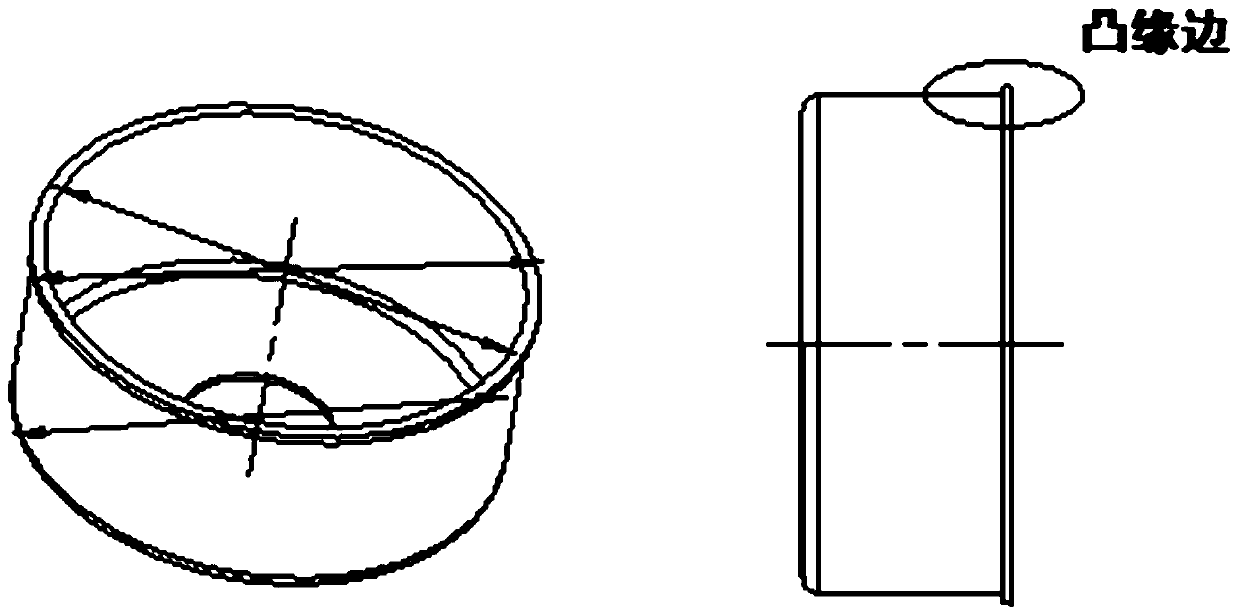

[0029] Step 2: The stamping parts of the micro-motor casing are lifted to the upper end, so that the stamping parts of the micro-motor casing enter the automatic identification product forward and reverse screening device sideways, and the flange edge enters the The inner chute of the screening device moves along the upper and lower inner chute under the weight and extrusion of the stamping parts.

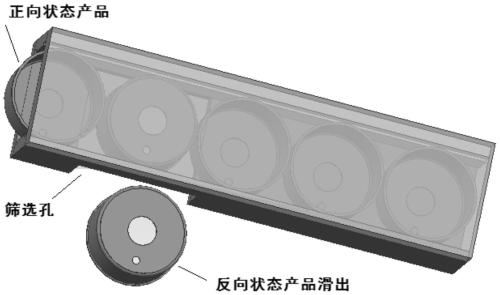

[0030] Step 3: The stamping part of the micro-motor casing moves forward to the screening hole of the screening orifice plate 3, and the motor casing in the positive state continues to move forward into the...

Embodiment 2

[0032] A screening method for automatic identification of product forward and reverse screening devices, the steps are as follows:

[0033] Step 1: Install the automatic identification product forward and reverse screening device on the upper end of the hoist and at the entrance of the pipeline, so that the screening holes of the screening orifice plate are horizontally 30° and vertically 20°.

[0034] Step 2: The stamping parts of the micro-motor casing are lifted to the upper end, so that the stamping parts of the micro-motor casing enter the automatic identification product forward and reverse screening device sideways, and the flange edge enters the The inner chute of the screening device moves along the upper and lower inner chute under the weight and extrusion of the stamping parts.

[0035] Step 3: The stamping part of the micro-motor casing moves forward to the screening hole of the screening orifice plate, and the motor casing in the forward state continues to enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com