Gypsum self-leveling mortar with temperature adjusting function and preparation method thereof

A technology of self-leveling mortar and gypsum, which is applied in the field of building materials, can solve the problems of poor fluidity, long working time, no temperature adjustment function, etc., and achieve the effect of high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 400g of high-strength gypsum prepared from natural gypsum, 70g of cement, 400g of sand, 110g of heavy calcium, and 20g of rubber powder (formed by spray drying of vinyl acetate-ethylene copolymer emulsion) as main ingredients; weigh 0.8g of water reducer, 0.8g of water retaining agent, 0.08g of retarder, and 0.4g of defoamer are used as admixtures; 100g of phase change material is weighed. Mix and stir the main ingredients, additives and phase change materials evenly to prepare gypsum-based self-leveling mortar.

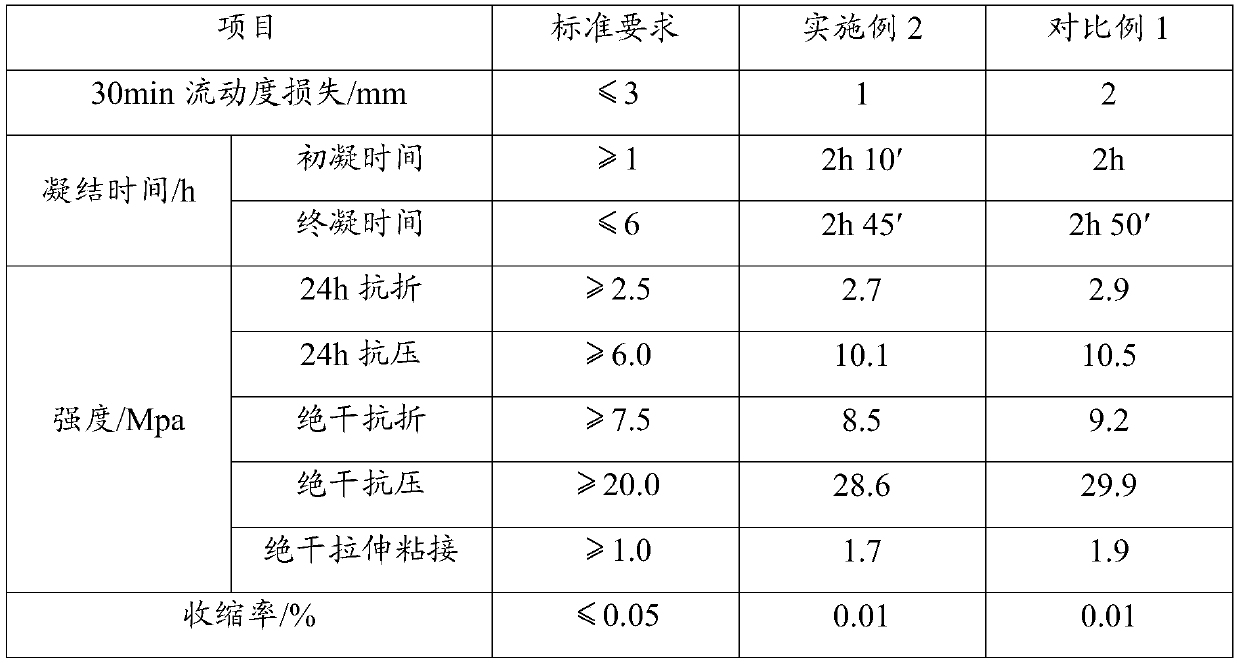

Embodiment 2

[0035] Weigh 300g of high-strength gypsum prepared from desulfurized gypsum, 150g of construction gypsum, 80g of cement, 350g of sand, 100g of heavy calcium, and 20g of rubber powder (formed by spray-drying of vinyl acetate-ethylene copolymer emulsion) as main ingredients; 0.8g of water-retaining agent, 0.6g of water-retaining agent, 0.09g of retarder, and 0.5g of defoamer are used as admixtures; 300g of phase change material is weighed. Mix and stir the main ingredients, additives and phase change materials evenly to prepare gypsum-based self-leveling mortar.

Embodiment 3

[0037] Weigh 450g of high-strength gypsum prepared from desulfurized gypsum, 75g of cement, 350g of sand, 110g of heavy calcium, and 15g of rubber powder (spray-dried from acrylic acid emulsion) as main ingredients; weigh 0.8g of water reducing agent and 0.7g of water retaining agent , retarder 0.1g, defoamer 0.6g as additives; weigh 300g of phase change material. Mix and stir the main ingredients, additives and phase change materials evenly to prepare gypsum-based self-leveling mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com