Ironing device for knitted fabric

An ironing device and technology for knitted fabrics, applied in the direction of fabric surface trimming, drying solid materials, drying gas arrangement, etc., can solve the inconvenience, the drying equipment and ironing equipment are not integrated, and the ironing effect of the fabric ironing device is not good Good and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

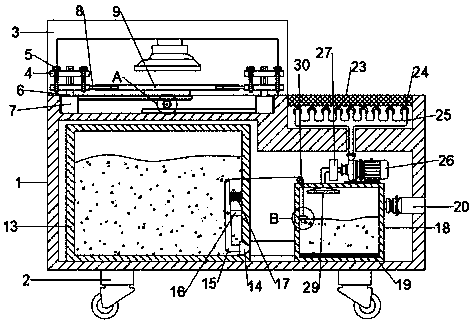

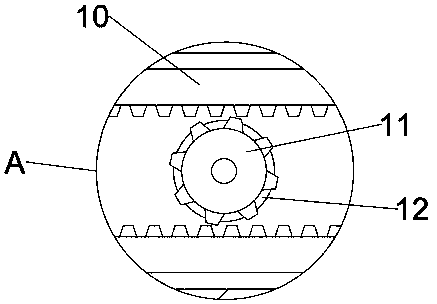

[0028] see Figure 1-5 , in an embodiment of the present invention, an ironing device for knitted fabrics, comprising a body 1, an ironing device 3 is installed and fixed on the body 1, and is used for ironing the cloth, and the upper surface of the body 1 is fixed and fixed There is a cloth spreader 9, and the upper surface of the body 1 is integrally formed with a chute, and a clamping mechanism is arranged symmetrically in the chute, which is used to fix the cloth and avoid wrinkles of the cloth during the ironing process. The tightening mechanism includes a slider 7, which is slidingly connected with the chute, and a support column 6 is installed and fixed longitudinally symmetrically on the slider 7, and a splint 4 is slidingly connected to the opposite surface of the support column 6 symmetrically in the vertical direction. Bolts 5 pass through and are threaded between the splints 4, toothed plates 10 are installed and fixed on the slider 7, racks are integrally formed o...

Embodiment 2

[0031] In this embodiment, a further improvement is made on the basis of embodiment 1, and the content of the improvement is that universal wheels 2 are symmetrically installed and fixed on the lower surface of the body 1, so as to facilitate the movement of the whole device.

[0032] A slide plate 8 is installed and fixed at one end of the splint 4, and the slide plate 8 is slidably inserted in the spreading plate 9, so as to avoid disconnected depressions between the splint 4 and the spreading plate 9, which will affect the ironing work.

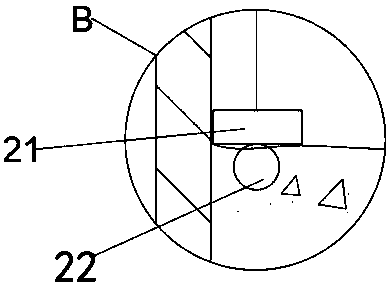

[0033] Further, since the heating of the heating plate 19 will gradually reduce the water in the second water tank 18, in order to supply water in the second water tank 18 in time, a first water tank 13 is installed and fixed in the body 1, and the first water tank 13 A fluid pipe is connected and fixed between the second water tank 8, and a valve mechanism is arranged in the first water tank 13 for controlling the water supply of the first...

Embodiment 1

[0034] In conjunction with embodiment 1, embodiment 2, working principle of the present invention is:

[0035]When using the present invention, by laying the cloth on the spreading board 9, and the two ends of the cloth pass through the splint 4, and under the action of the bolt 5, the two ends of the cloth are fixed, and then rotated by the stepping motor 12, thereby driving the gear 11 rotates, thereby driving the tooth plate 10 to move towards each other, driving the splint 4 to move towards each other, and pulling the cloth to both sides until the cloth is flat and wrinkle-free, the water in the second water tank 18 is heated by the heating plate 19, and the water in the second water tank 18 is heated by the exhaust fan 26 function, the warm gas in the second water tank 18 is injected into the drying column 24 through the water pipe 25, and the water vapor in the warm gas is absorbed through the drying box 27 halfway, and the injection of the warm gas drives the drying colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com