Ecological demolition system and construction method of cast-in-place box girder with piers retained

A box girder and pier column technology is applied to the ecological demolition system and construction field of retaining cast-in-place box girder for pier columns, which can solve the problems of pier column damage, waste of resources, high construction intensity, etc. , the effect of low construction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

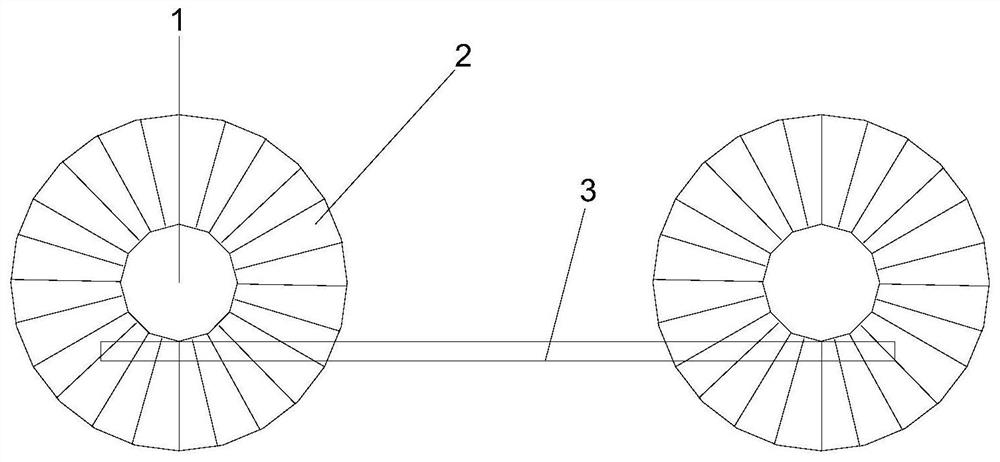

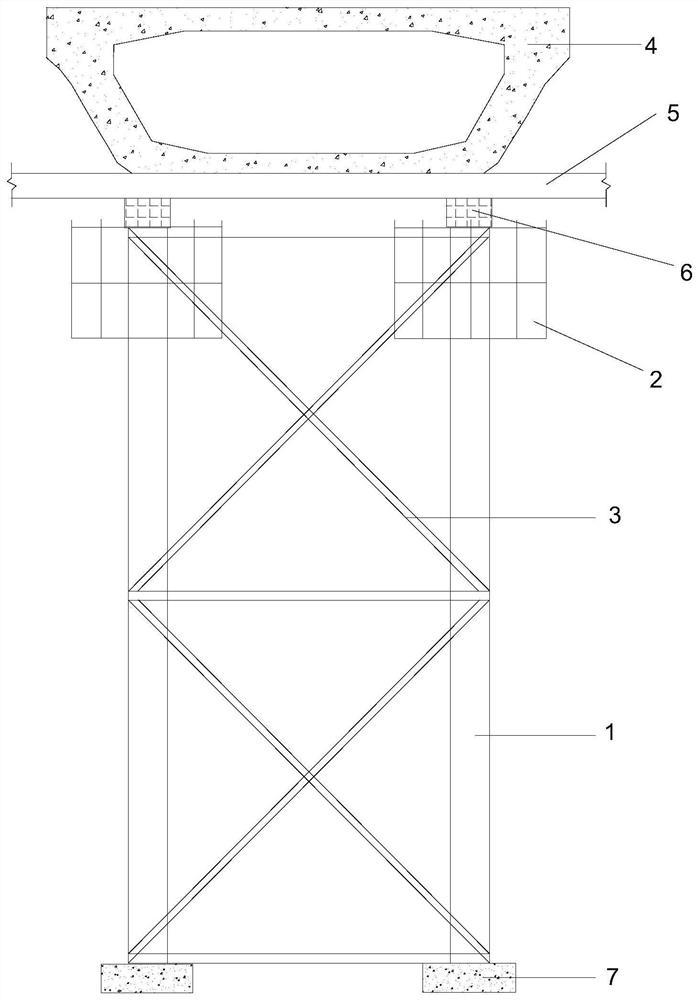

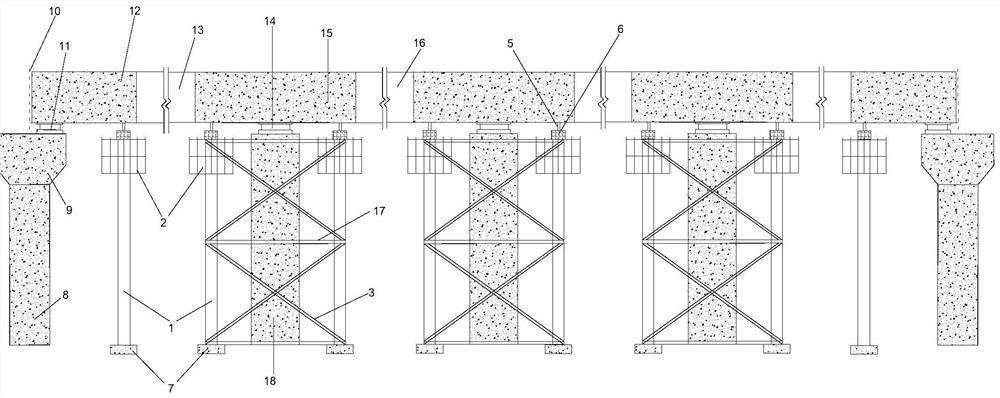

[0053] Such as Figure 1-Figure 15 As shown, the pier column retains the cast-in-place box girder ecological demolition system, and the bottom of the box girder is jointly supported by a plurality of mid-span pier columns 18 and side-span pier columns 8, wherein a cover beam 9 is fixed on the top of the side-span pier column 8, and the cover beam 9 is fixed on the top of the side-span pier column. The top of the beam 9 supports the box girder 4 through the side-span support 11, and the top of the mid-span pier column 18 supports the box girder 4 through the mid-span support 14, and the side-span pier column 8 and the mid-span pier column 18 are retained during the removal of the box girder 4 , and around each mid-span pier column 18 below the box girder 4, a plurality of steel pipe pile columns 1 distributed vertically and horizontally are vertically ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com