Intelligent steel rolling negative difference early warning system and early warning method thereof

An early warning system and intelligent technology, applied in transmission systems, database management systems, alarms, etc., can solve problems such as lack of unified adjustment standards, increased labor intensity, and company economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

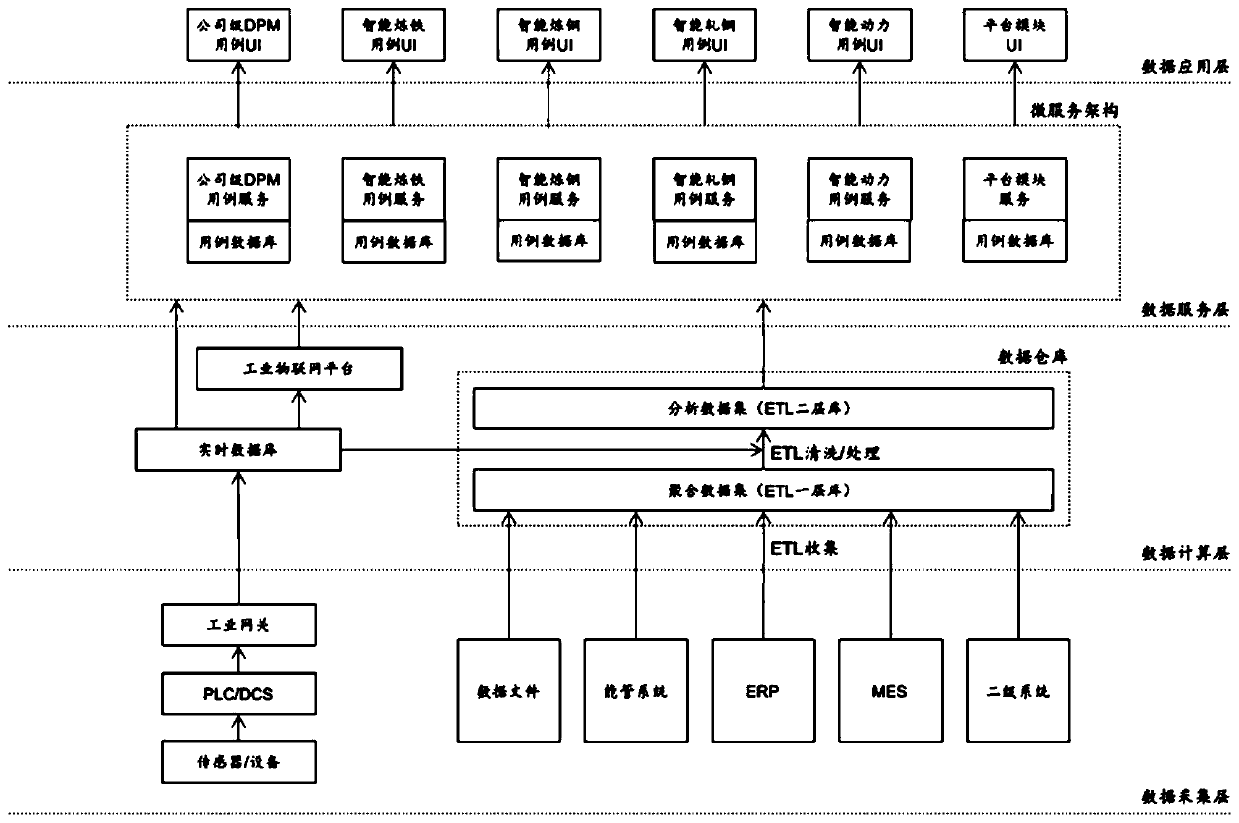

[0041] Such as figure 1 As shown, an intelligent negative difference early warning system for steel rolling includes the following four-layer architecture from bottom to top: data acquisition layer, data calculation layer, data service layer and data application layer.

[0042] Data acquisition layer: includes all data sources, one part is hot data source, that is, real-time data collected by PLC / DCS directly connected to the on-site industrial gateway and various industrial sensors and equipment under it; the other part is cold data source, namely ERP , energy management system, MES, secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com