Preparation method of Ag2S-Sb2S3 co-sensitized ZnO-based photo-anode

An ag2s-sb2s3, co-sensitization technology, applied in electrical components, nanotechnology, circuits, etc., to achieve the effect of a wide range of applications and a simple and controllable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

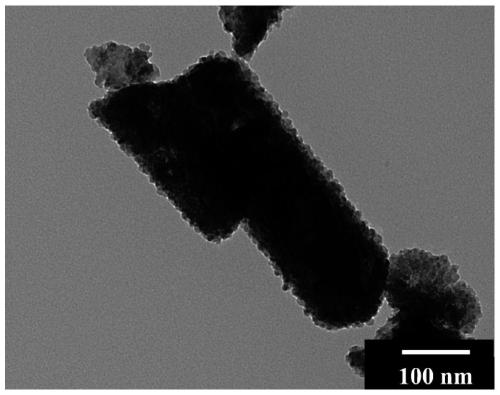

Embodiment 1

[0012] The Ag provided in this example 2 S-Sb 2 S 3 The preparation method of the co-sensitized ZnO-based photoanode is to first generate ZnO nanorod arrays on the surface of ITO conductive glass, and then based on the continuous ion layer adsorption reaction method, the above-mentioned ITO glass with ZnO nanorods generated in 0.1M Na 2 React in S aqueous solution at 30°C for 10min, then wash in deionized water for 30s and blow dry with nitrogen; after that, in 0.05M AgNO 3 React in aqueous solution at 30°C for 5min, then wash in deionized water for 30s and blow dry with nitrogen; then in 0.1M Na 2 React in S aqueous solution at 30°C for 10min, then wash in deionized water for 30s and blow dry with nitrogen; then in 0.067M SbCl 3 React in ethanol solution at 30°C for 20min, then wash in ethanol for 30s and blow dry with nitrogen; repeat the above reaction process 5 times and dry in a blast drying oven at 60°C for 30min; finally make it on the surface of ITO conductive glass...

Embodiment 2

[0014] The Ag provided in this example 2 S-Sb 2 S 3 The preparation method of the co-sensitized ZnO-based photoanode is to first generate ZnO nanowire arrays on the surface of ITO conductive glass, and then based on the continuous ion layer adsorption reaction method, the above-mentioned ITO glass with ZnO nanowires generated in 0.05M Na 2 React in S aqueous solution at 30°C for 10min, then wash in deionized water for 30s and blow dry with nitrogen; then in 0.025M AgNO 3 React in an aqueous solution at 30°C for 5 min, then wash in deionized water for 30 s and blow dry with nitrogen; then in 0.05M Na 2 React in S aqueous solution at 30°C for 10min, then wash in deionized water for 30s and blow dry with nitrogen; then in 0.033M SbCl 3 React in ethanol solution at 30°C for 20min, then wash in ethanol for 30s and blow dry with nitrogen; repeat the above reaction process 5 times and dry in a blast drying oven at 60°C for 30min; finally make it on the surface of ITO conductive gl...

Embodiment 3

[0016] The Ag provided in this example 2 S-Sb 2 S 3 The preparation method of the co-sensitized ZnO-based photoanode is to first generate ZnO nanosheet arrays on the surface of ITO conductive glass, and then based on the continuous ion layer adsorption reaction method, the above-mentioned ITO glass with ZnO nanosheets generated in 0.05M Na 2 React in S aqueous solution at 30°C for 10min, then wash in deionized water for 30s and blow dry with nitrogen; then in 0.025M AgNO 3 React in an aqueous solution at 30°C for 5 min, then wash in deionized water for 30 s and blow dry with nitrogen; then in 0.05M Na 2 React in S aqueous solution at 30°C for 10min, then wash in deionized water for 30s and blow dry with nitrogen; then in 0.033M SbCl 3 React in ethanol solution at 30°C for 20min, then wash in ethanol for 30s and blow dry with nitrogen; repeat the above reaction process 10 times and dry in a blast drying oven at 60°C for 30min; finally make it on the surface of ITO conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com