Process method for preparing nano-silver disinfectant based on electric explosion process

A process method and nano-silver technology, which is applied in the field of nano-technology and fine chemical industry, can solve the problems of complex preparation methods, long preparation cycle, and high cost of nano-silver disinfectant, and achieve high-efficiency, fast and flexible preparation, high cost performance, and reduced preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

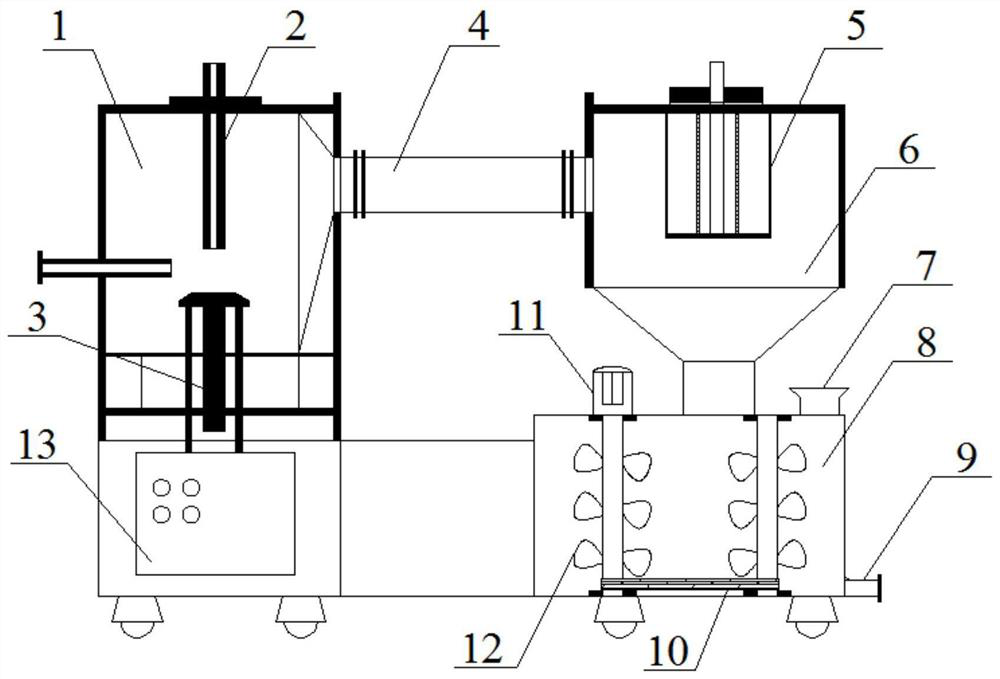

Method used

Image

Examples

Example Embodiment

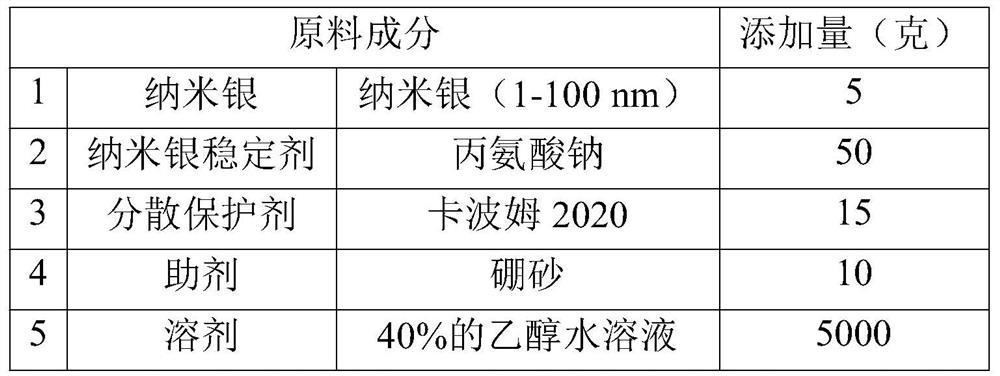

[0026] Example 1:

[0027] The raw materials of nano silver disinfectant are as follows:

[0028]

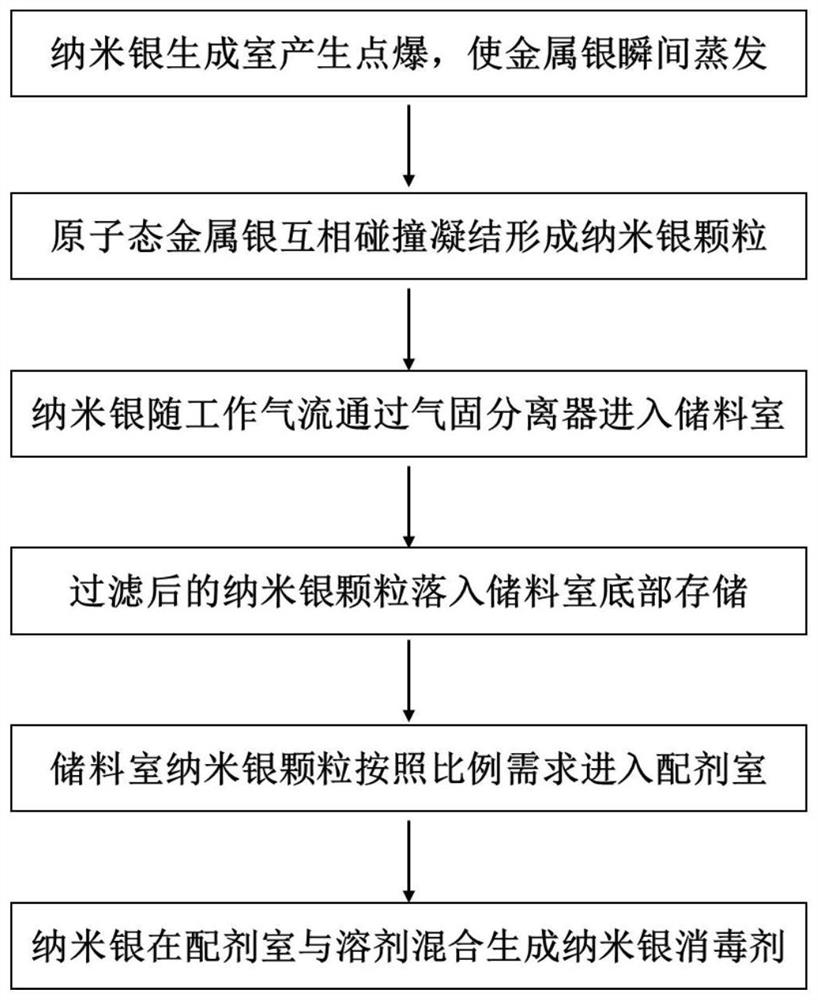

[0029] Preparation method: start the power supply of the device, adjust the voltage of the three cathodes and anodes inside the nano-silver generating chamber to 10kV, set the anode silver rod feed rate to 0.1mm / min, and the working gas purge rate to 10m 3 / min, the production rate of nano silver is 10g / min. The nano silver enters the storage chamber with the airflow and is separated by the gas-solid separator, and falls into the bottom for storage. Nano-silver enters the dispensing chamber from the storage chamber at a feed rate of 5g / min. Nano-silver stabilizers, dispersion protectants, additives, and solvents are used at 50g / min, 15g / min, 10g / min, and 5000g / min. The feed rate is added to the dosing chamber from the feed tank. All the raw materials are mixed evenly in the dispensing chamber to obtain a stable nano-silver disinfectant, which is then extracted from the discharge po...

Example Embodiment

[0031] Example 2:

[0032] The raw materials of nano silver disinfectant are as follows:

[0033]

[0034] Preparation method: start the power supply of the device, adjust the voltage of the three cathodes and anodes inside the nano-silver generating chamber to 20kV, set the anode silver rod feed rate to 0.2mm / min, and the working gas purge rate to 10m 3 / min, the production rate of nano silver is 20g / min. The nano-silver enters the storage chamber with the airflow and is separated by the gas-solid separator and falls to the bottom. Nano-silver enters the dispensing chamber from the storage compartment at a feed rate of 10g / min. Nano-silver stabilizers, dispersion protectants, additives, and solvents are used at 70g / min, 30g / min, 20g / min, and 5000g / min. The feed rate is added to the dosing chamber from the feed tank. All the raw materials are mixed evenly in the dispensing chamber to obtain a stable nano-silver disinfectant, which is then extracted from the discharge port.

[0035...

Example Embodiment

[0036] Example 3:

[0037] The raw materials of nano silver disinfectant are as follows:

[0038]

[0039] Preparation method: start the power supply of the device, adjust the voltage of a pair of cathode and anode inside the nano-silver generating chamber to 10kV, set the anode silver rod feed rate to 0.1mm / min, and the working gas purge rate to 10m 3 / min, the production rate of nano silver is 4g / min. The nano-silver enters the storage chamber with the airflow and is separated by the gas-solid separator and falls to the bottom. Nano-silver enters the dispensing chamber from the storage compartment at a feed rate of 2g / min. Nano-silver stabilizers, dispersion protectants, additives, and solvents are used at 30g / min, 8g / min, 7g / min, and 5000g / min. The feed rate is added to the dosing chamber from the feed tank. All the raw materials are mixed evenly in the dispensing chamber to obtain a stable nano-silver disinfectant, which is then extracted from the discharge port.

[0040] Disi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap