Steaming and baking oven, control method of steaming and baking oven and integrated cooker with steaming and baking oven

A technology of steaming oven and steaming and baking, which is applied in the field of integrated stoves, which can solve the problems of reducing the safety of use, shortening the service life, and poor heat dissipation effect, and achieves the effect of ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

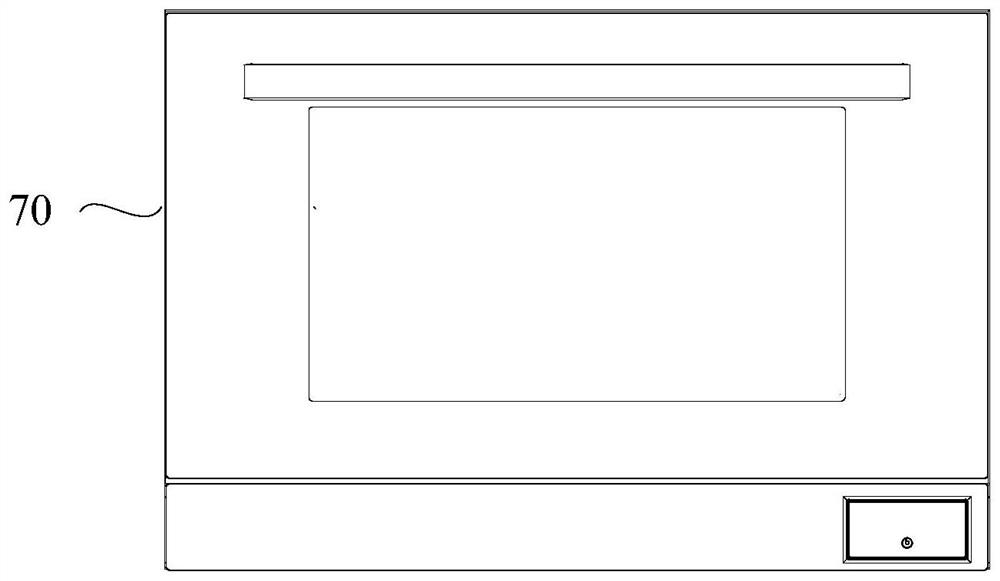

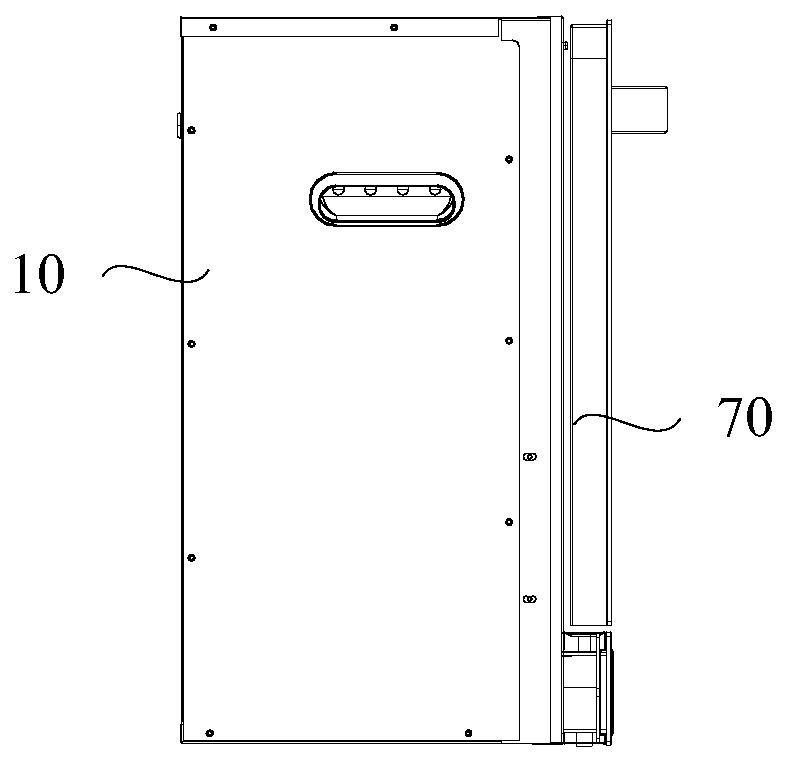

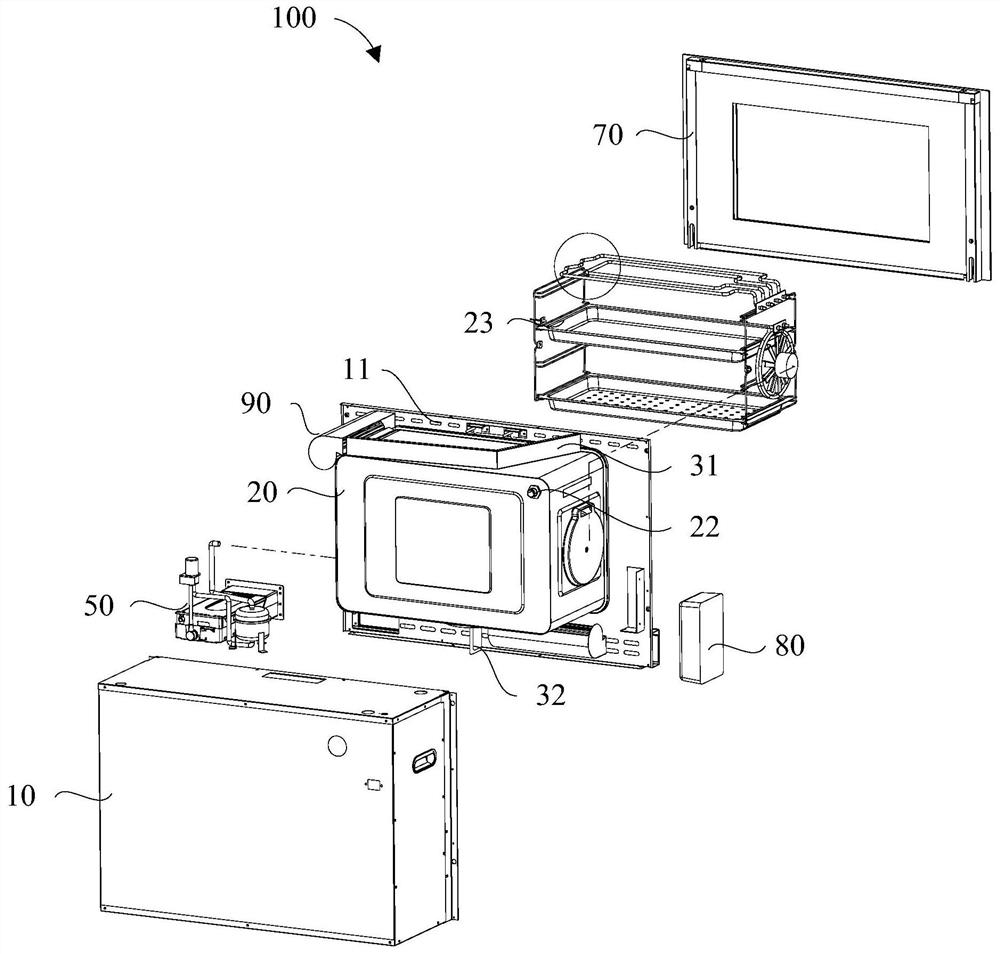

[0044] figure 1 It is the front view of the steam oven provided by Embodiment 1 of the present invention. figure 2 It is a side view of the steam oven provided in Embodiment 1 of the present invention. image 3 It is an exploded view of the steam oven provided in Embodiment 1 of the present invention. Figure 4 It is a structural schematic diagram of a part of the accommodating cavity of the steam oven provided in Embodiment 1 of the present invention. Figure 5 It is a top view of a part of the accommodating cavity of the steam oven provided in Embodiment 1 of the present invention. Figure 6 It is a schematic diagram of the external structure of the steaming inner container of the steaming oven provided in Embodiment 1 of the present invention. Figure 7 It is a schematic diagram of the internal structure of the steaming and baking liner of the steaming oven provided in Embodiment 1 of the present invention.

[0045] refer to Figure 1 to Figure 7 As shown, Embodiment ...

Embodiment 2

[0075] Figure 8 It is a schematic flowchart of the control method of the steam oven provided in the second embodiment of the present invention. refer to Figure 8 As shown, on the basis of the first embodiment above, the second embodiment of the present invention provides a method for controlling a steam oven.

[0076] Specifically, the control method of the steam oven is used to control the steam oven in Embodiment 1, and the control method of the steam oven includes:

[0077] S1: When the steam oven is turned on, simultaneously turn on the steam generating device, the heating device and the cooling device of the steam oven according to the opening information of the steam oven.

[0078] S2: When the steam oven is turned off, turn off the steam generating device and the heating device of the steam oven according to the closing information of the steam oven.

[0079] S3: Obtain the real-time temperature in the steaming and roasting liner of the steaming oven and the workin...

Embodiment 3

[0088] Figure 9 It is a schematic structural diagram of the integrated cooktop provided by Embodiment 3 of the present invention. refer to Figure 9 As shown, on the basis of the first or second embodiment above, the third embodiment of the present invention provides an integrated cooker 200 .

[0089] It should be noted that the steam oven 100 can be set in the integrated cooker 200, and the integrated cooker 200 can further include a gas cooker 202 arranged on the operating table top of the steaming oven 100 (pots 203 can be placed on the operating table or the gas cooker 202 ), and the range hood 201 arranged on the top of the entire integrated stove 200, the control device 80 of the steam oven 100, the gas stove 202 and the range hood 201 can all be electrically connected with the control device of the integrated stove 200, so as to realize the integrated stove 200 The integrated linkage control improves the operability and convenience of the integrated cooker 200.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com