Adsorption tower for preventing dust from accumulating in air chambers and method for treating flue gas by utilizing adsorption tower

An adsorption tower and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of corrosion of the bottom wall, accelerated agglomeration, and active coke turning out from the grids on both sides of the bed. Problems such as the bottom area of the air inlet chamber to achieve a good effect of preventing dust accumulation and preventing dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

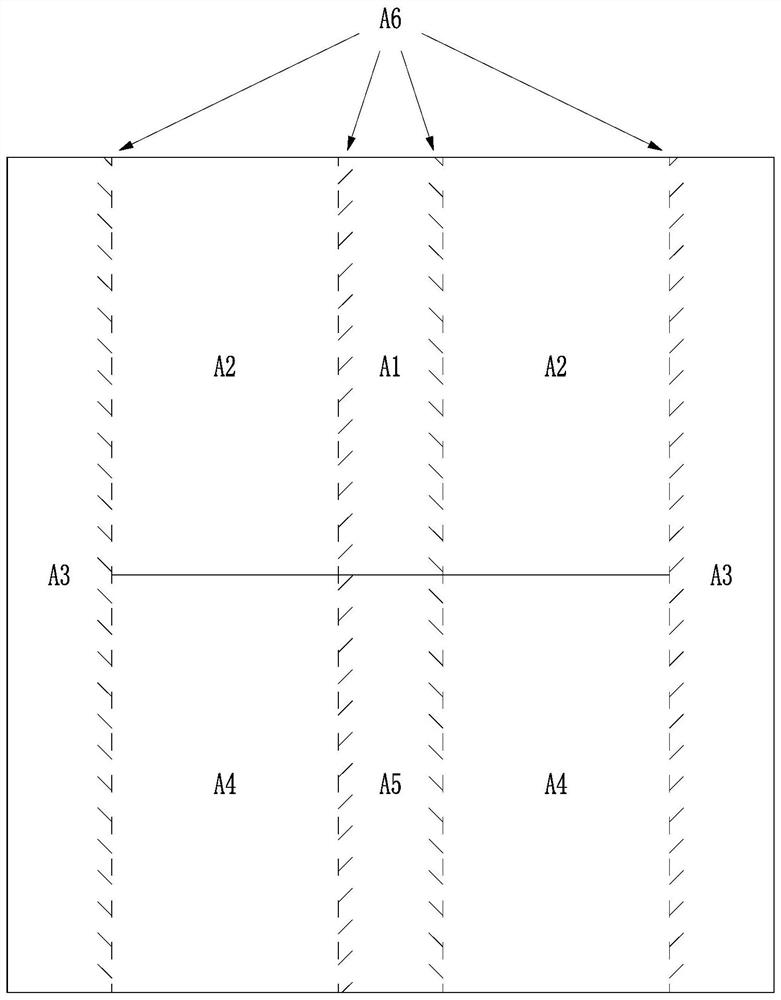

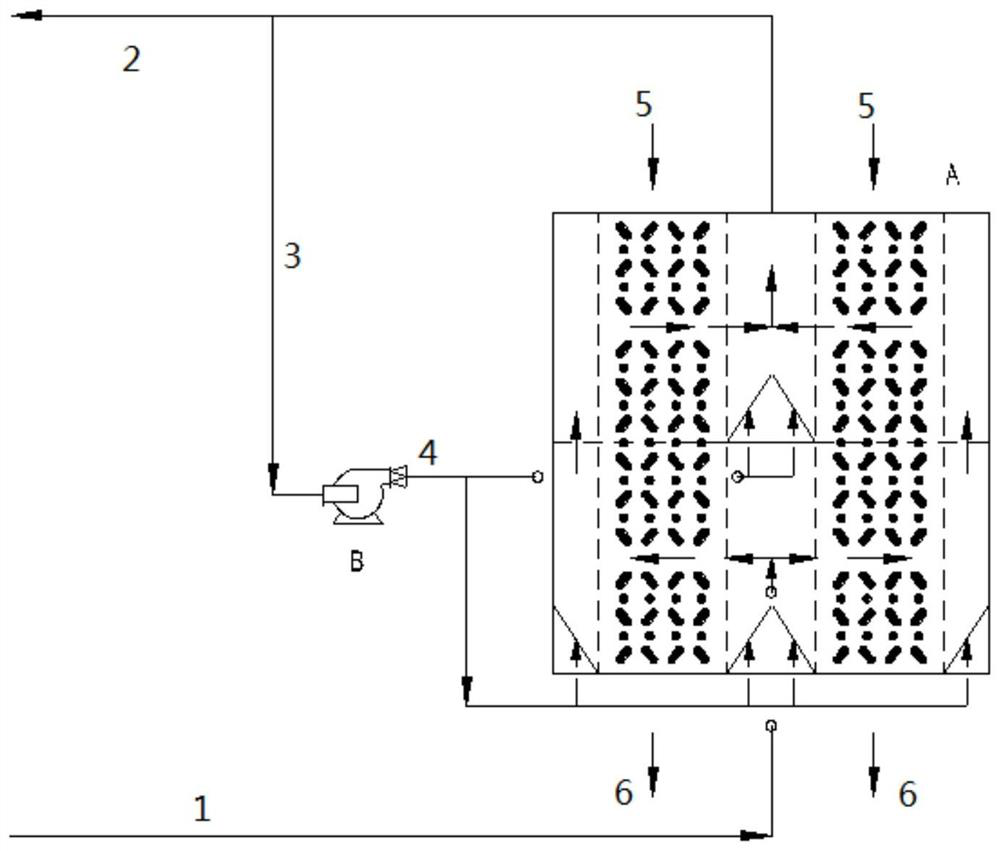

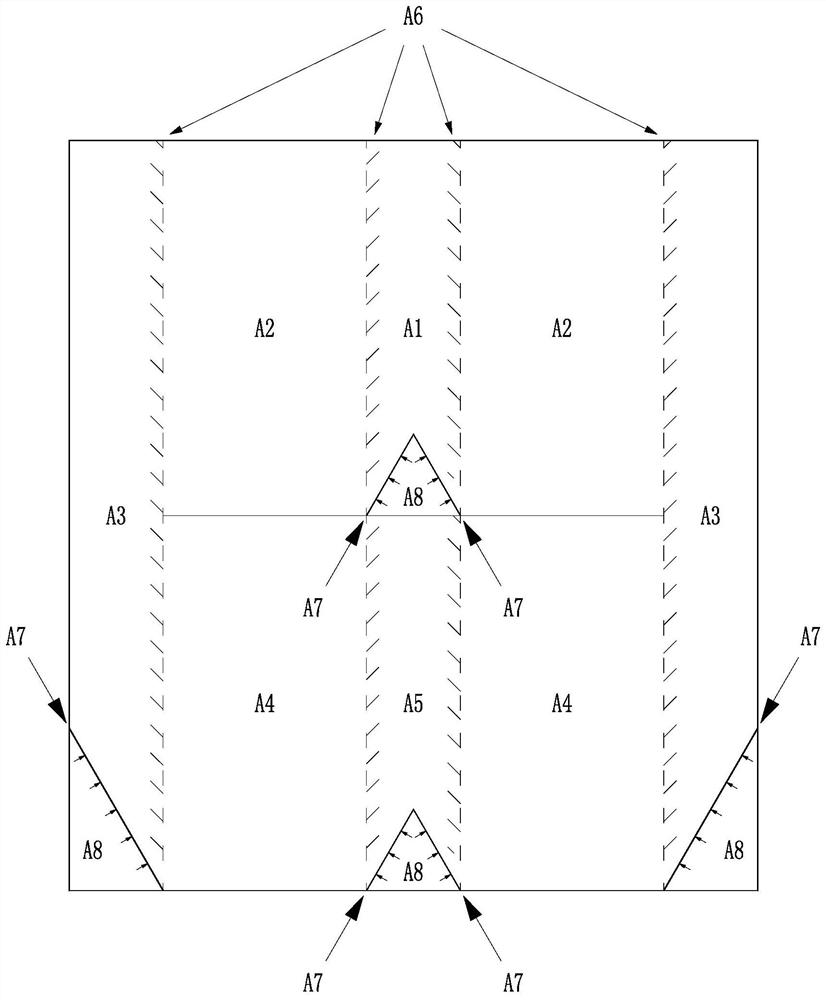

[0038] The structure of adsorption tower A used to treat flue gas is as follows: image 3 As shown, the internal structure of the adsorption tower A is provided with the original flue gas inlet area A5 and the net flue gas outlet area A1 from bottom to top, and the lower cross-flow adsorption area located outside the original flue gas inlet area A5 and the net flue gas outlet area A1 respectively. Area A4 and the upper cross-flow adsorption area A2, and the flue gas redistribution area A3 located outside the lower cross-flow adsorption area A4 and the upper cross-flow adsorption area A2;

[0039] The upper cross-flow adsorption area A2 and the lower cross-flow adsorption area A4 are run through by the active coke redistribution section, and are respectively connected to the flue gas redistribution area A3 through the distribution grid. The upper cross-flow adsorption area A2 and the lower cross-flow adsorption area A4 are There is an active coke bed;

[0040] The upper cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com