Kitchen garbage biological treatment machine with hard garbage crushing function and control method

A technology for processing machine and garbage, applied in grain treatment, gas treatment, separation method, etc., can solve the problem of low garbage fermentation efficiency, and achieve the effect of avoiding odor, reducing residue and improving fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

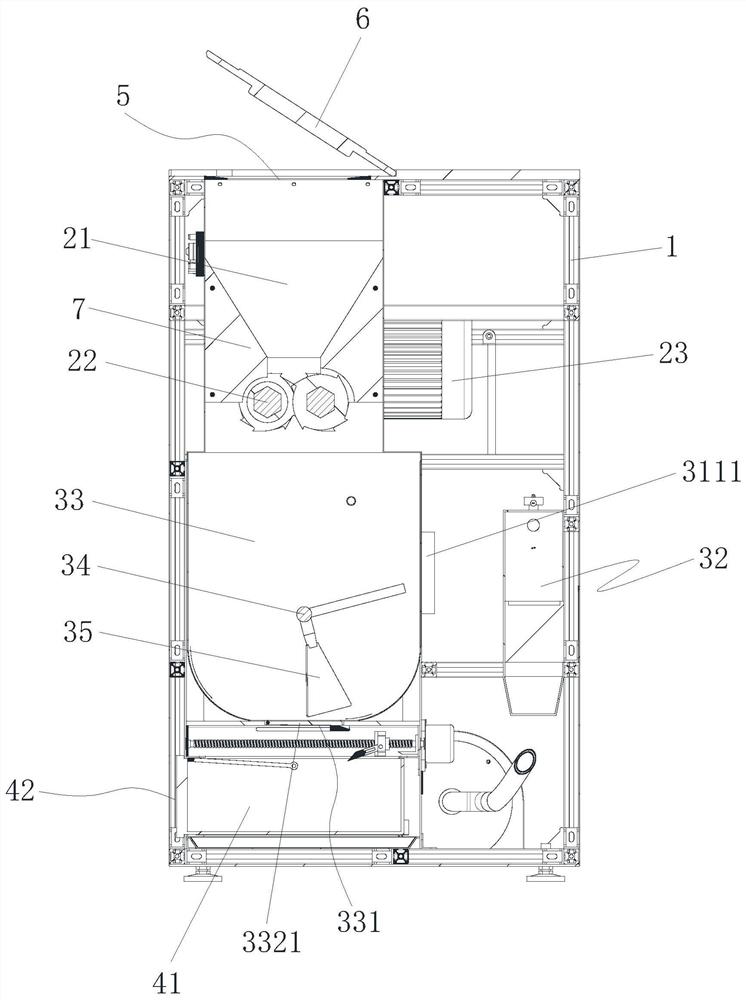

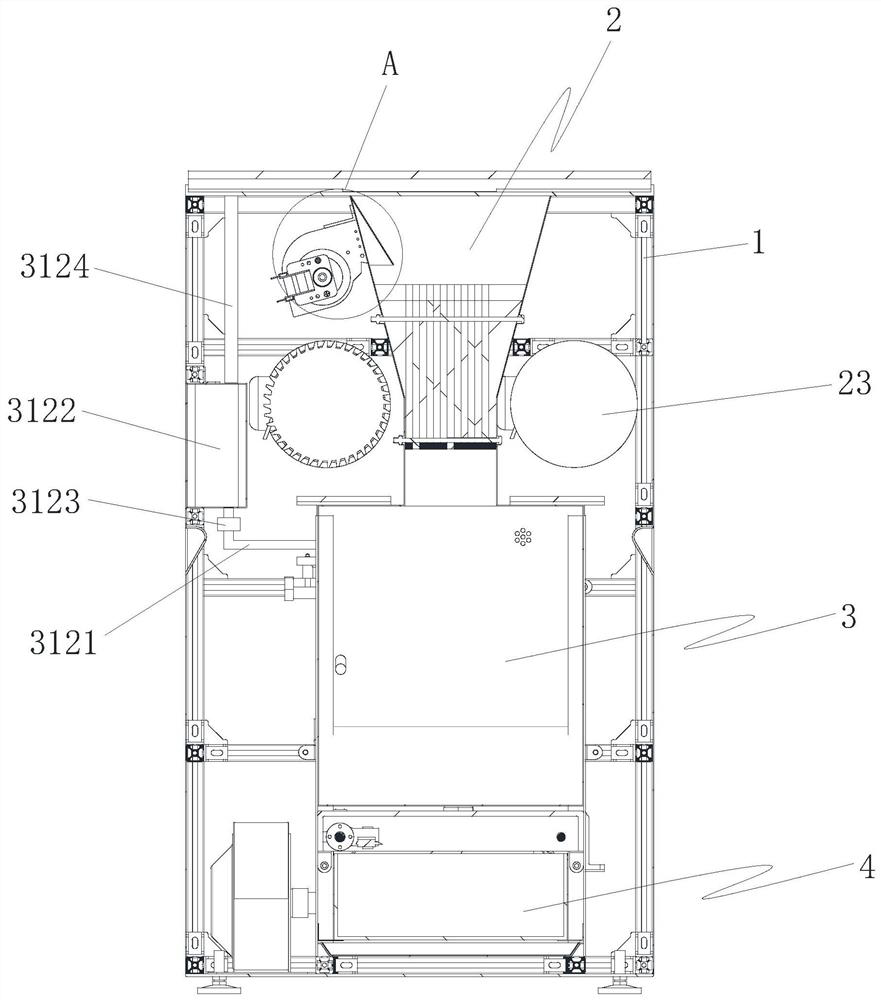

[0043] combined with figure 1 and 4 , a food waste biological processor with the function of crushing hard waste in this embodiment includes a crushing device 2, a fermentation device 3 and a discharge device 4 connected in sequence, wherein the crushing device 2 is used for crushing food waste Garbage; the fermentation device 3 is used to stir the broken kitchen waste; the discharge device 4 is used to discharge the broken, stirred and fermented kitchen waste;

[0044] Wherein, the crushing box 21 is provided with a cleaning assembly 211, and the cleaning assembly 211 is used to inject gas into the fermentation device 3 through the crushing device 2; the fermentation device 3 is connected with a gas purification module 32, and the gas purification module 32 is used to purify the gas in the fermentation device 3 and discharge it; the fermentation device 3 is provided with an oxygen sensor, and both the oxygen sensor and the gas purification module 32 are electrically connecte...

Embodiment 2

[0048] combined with figure 1 and 4 , a biological kitchen waste processor with the function of crushing hard waste in this embodiment, compared with Embodiment 1, the biological kitchen waste processor with the function of crushing hard waste according to claim 1 , it is characterized in that: the crushing device 2 includes a crushing box 21, at least two crushing rollers 22 arranged in the crushing box 21, and a crushing drive member 23 for driving the crushing rollers 22 to rotate and for detecting the working state of the crushing rollers. The detection sensor, the crushing drive 23 and the detection sensor are both electrically connected to the controller; the detection sensor is at least one of a resistance sensor, a temperature sensor, a vibration sensor, and a current sensor.

[0049] Existing kitchen waste composters often use a blade-type crushing device, which cannot crush hard kitchen waste. The present invention can crush hard kitchen waste such as animal bones, ...

Embodiment 3

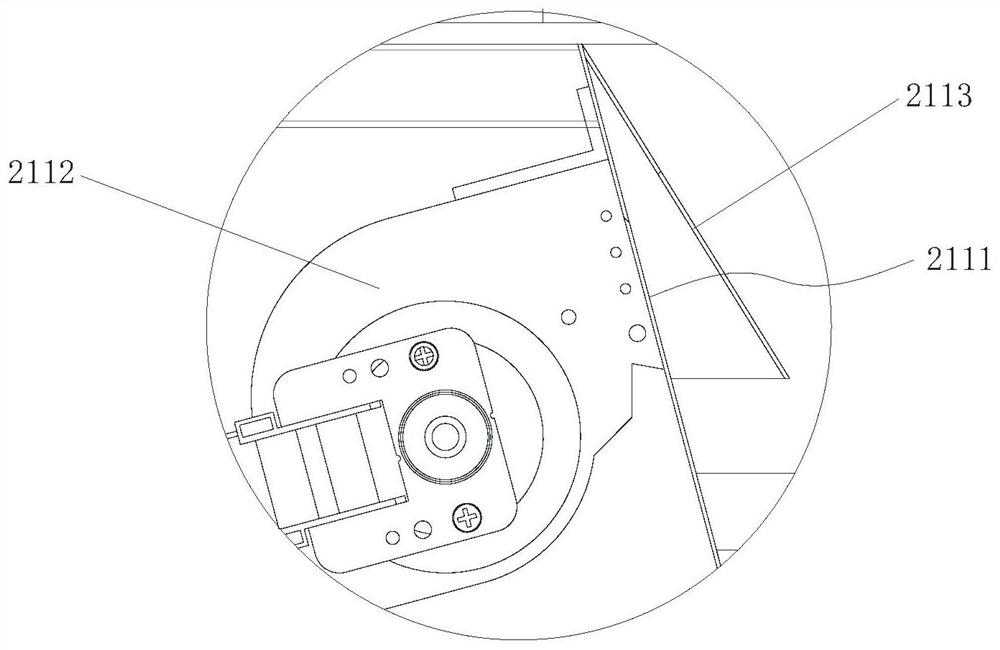

[0053] combined with figure 1 and 4 , a kitchen waste biological processor with the function of crushing hard waste in this embodiment, compared with Embodiment 1 or 2, the cleaning component 211 includes an air injection hole 2111 provided on the crushing box 21 for injecting The cleaning driver 2112 for injecting gas into the crushing box 21 and the deflector 2113 for guiding the gas to the crushing roller 22 .

[0054] The steps for cleaning the crushing box 21 by the cleaning component 211 in this embodiment are as follows: the cleaning driver 2112 injects gas from the gas injection hole 2111 into the crushing box 21, and the gas injected into the crushing box 21 passes through the flow guide of the deflector 2113 The gas is blown to the crushing roller 22. When the gas passes through, the kitchen waste on the inner wall of the crushing box 21 and on the surface of the crushing roller 22 can be washed out from the bottom of the crushing box 21 to achieve the purpose of cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com