Die for four-sided side trimming of protruding amount of inner and outer cones of truck

A technology of trimming molds and molds, which is applied in the field of mold processing, can solve problems such as excessively high protruding edge heights, and achieve the effects of saving labor costs, ensuring the rate of finished products, and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

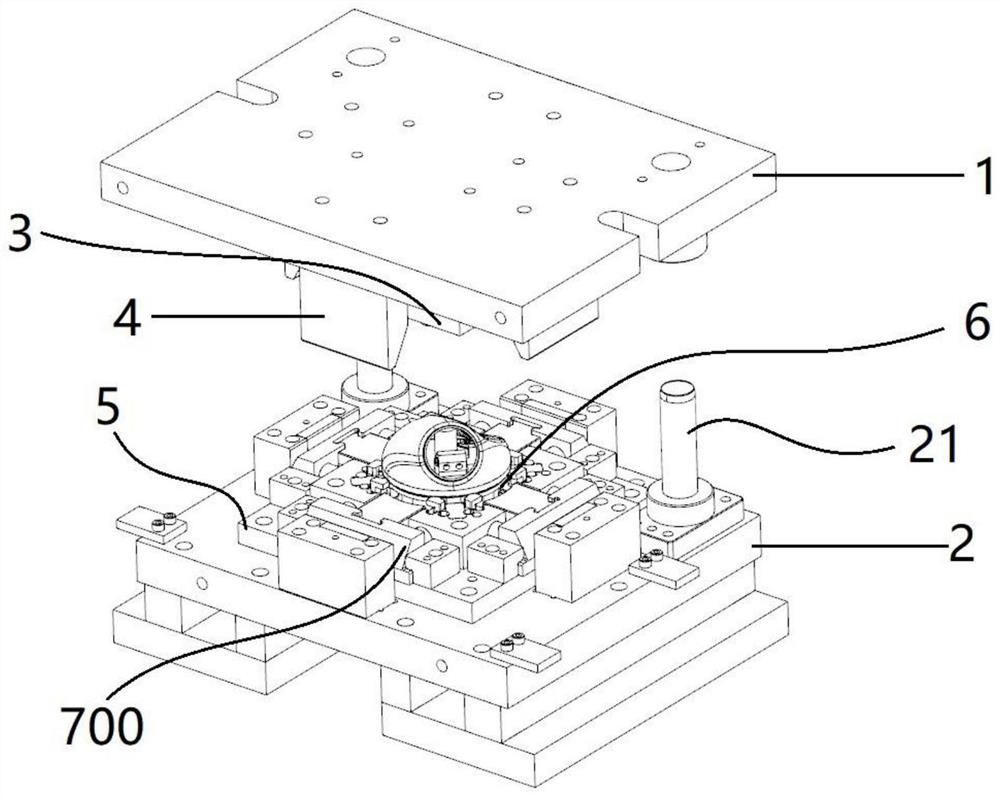

[0034] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0035] Refer below Figure 1-Figure 11 Describe in detail a four-sided side trimming mold for truck inner and outer cone protrusions disclosed in this application.

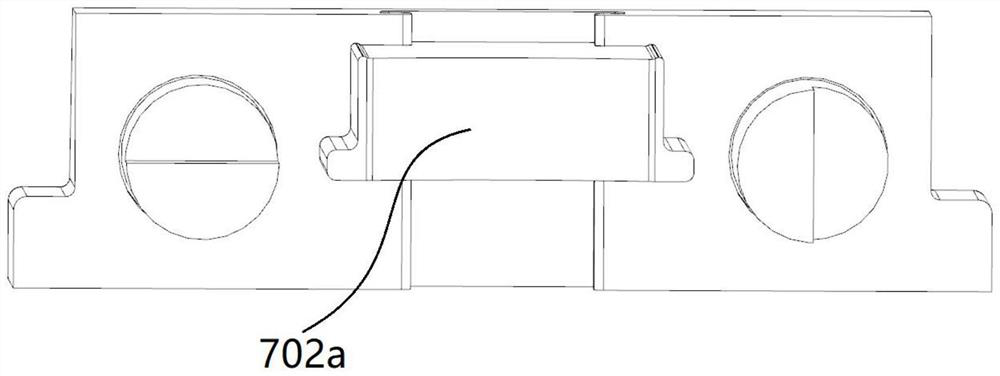

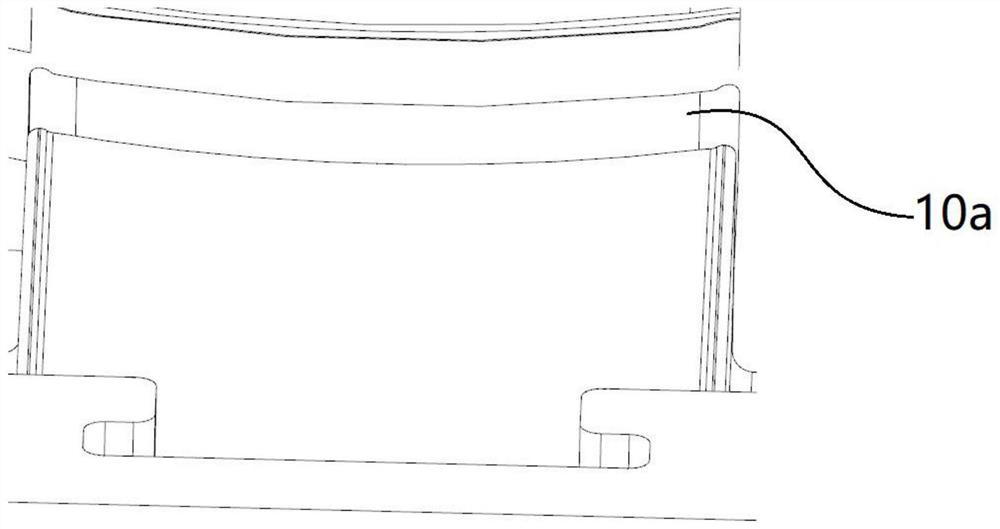

[0036] On the one hand, embodiment one is disclosed, such as Figure 1-Figure 9 As shown, a four-sided side trimming mold for the inner and outer cones of trucks includes: an upper die base 1 and a lower die base 2, and a profiling press block 3 is fixedly installed in the middle area of the upper die base 1, and the profiling press block 3. The shape of the area facing the lower mold base 2 matches the shape of the outer cone of the inner and outer cone assembly 22. It is driven by the press and moves in the vertical direction to fix and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com