Alkali-activated cementing material and using method thereof

A cementing material and alkali-activated technology, which is applied in the field of building materials, can solve problems such as too fast setting time and complicated construction procedures of liquid alkali activators, and achieve the effects of convenient construction, excellent mechanical properties, and convenient operation

Active Publication Date: 2020-09-01

NORTHEAST FORESTRY UNIVERSITY

View PDF9 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The object of the present invention is to provide an alkali-activated gelling material and its use method to sol

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

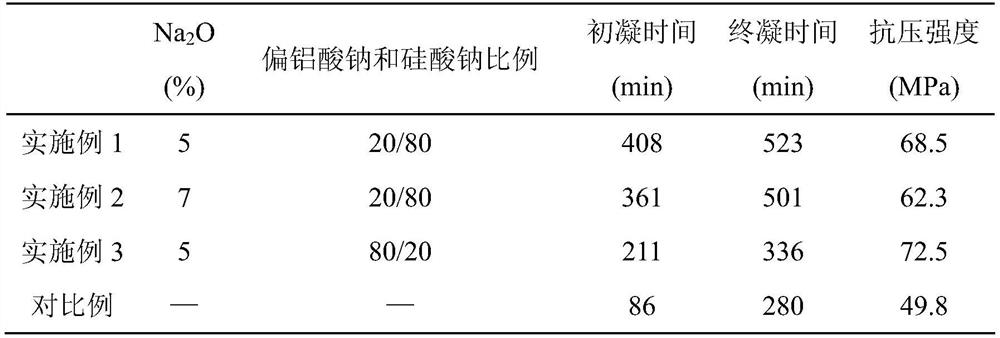

The invention discloses an alkali-activated cementing material and a using method thereof, belongs to the technical field of building materials, and solves the problems of complex construction procedures and too short setting time in preparation of a liquid alkali activator. The alkali-activated cementing material is prepared by adding solid alkali activators into granulated blast furnace slag fine powder, the solid alkali activators are sodium metaaluminate and sodium silicate, the mass of the solid alkali activators is 3-11% of the mass of the granulated blast furnace slag fine powder, and the mass ratio of sodium metaaluminate to sodium silicate is 4: 1 to 1: 4. The using method comprises the following steps: weighing the components with corresponding masses according to the mixing ratio requirements, slowly dry-stirring, slowly pouring a proper amount of water, slowly stirring, and quickly stirring. The 28d compressive strength of the cementing material at the optimal mix proportion is 1.5 times that of PO 42.5R cement, the cementing material can be directly mixed with water for use, the setting time is moderate and can be adjusted according to different proportions of sodium metaaluminate and sodium silicate, and the cementing material is low-carbon, environmentally friendly and good in engineering application prospect.

Description

technical field [0001] The invention belongs to the technical field of building materials, and in particular relates to an alkali-activated gelling material and a using method thereof. Background technique [0002] Alkali activated gelling material is a kind of hydraulic gelling material obtained by using alkali metal compound as alkali component to activate slag. The goal is to be used as a cementitious material to replace cement. The resource, energy and environmental problems of cement are very prominent. It consumes a lot of natural resources and energy consumption, and emits dust and harmful gases to pollute the environment. The granulated blast furnace slag is an industrial by-product of iron and steel smelting, with a huge output and low utilization rate. At present, it is mostly discharged as solid waste. At the same time, the granulated blast furnace slag is a polymer rich in glass phase, and the glass phase content accounts for about 90%. It is transformed into a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B40/00C04B40/02

CPCC04B28/006C04B40/0067C04B40/02C04B2201/50C04B2111/00017C04B18/141C04B22/08C04B22/00

Inventor 王钧陈斌王欣然伊心宇段玉鑫刘奇

Owner NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com