Solvent-resistant polyphenyl ether composition

A polyphenylene ether and composition technology, which is applied in the polymer field, can solve the problems that restrict the wide application and application of modified composite materials and the high price of PA46 resin, and achieve the effects of easy processing, low relative cost and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

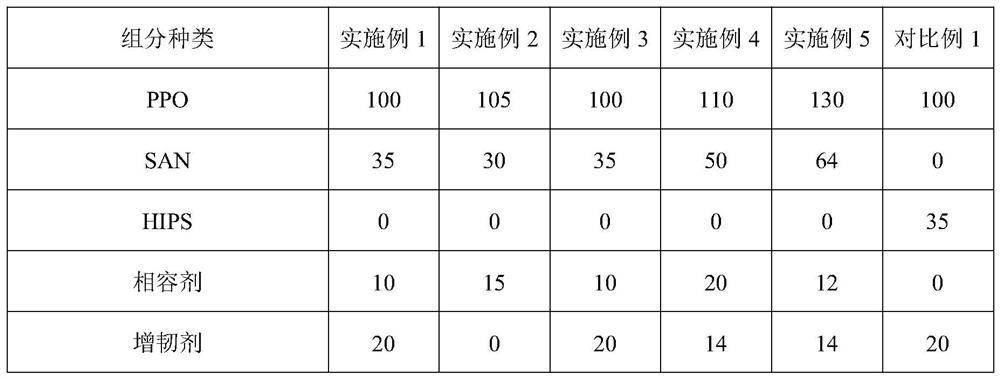

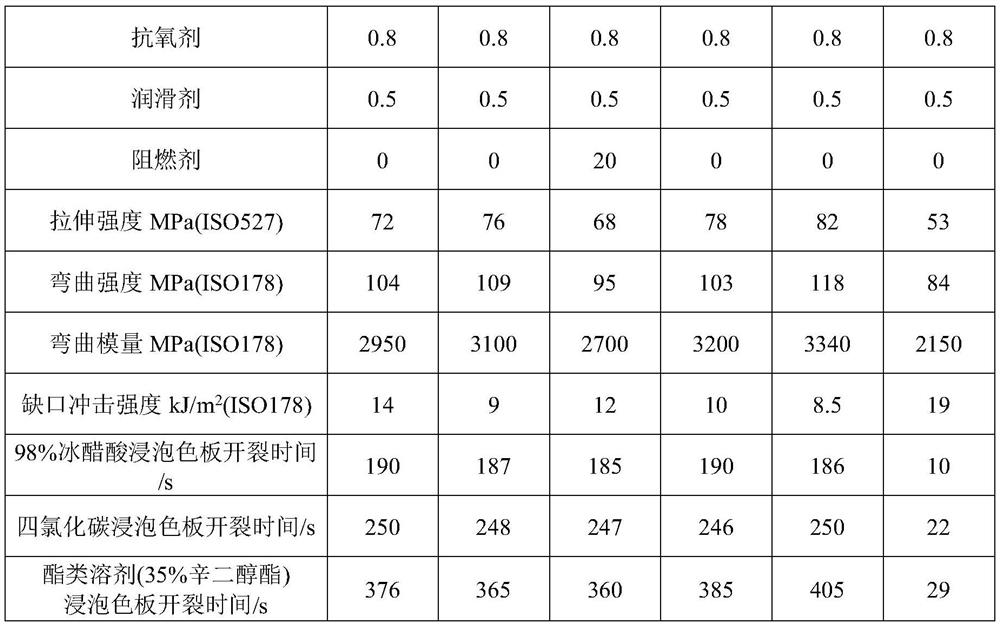

Embodiment 1

[0036] Example 1: A solvent-resistant polyphenylene ether composition prepared from the following components in parts by weight: 100 parts of PPO (with an intrinsic viscosity of 38 cm3 / g), 35 parts of SAN, 10 parts of a compatibilizer, 20 parts of Toughener, 0.8 part antioxidant, 0.5 part lubricant.

[0037] The compatibilizer is SEBS-g-MAH;

[0038] The toughening agent is SEBS;

[0039] Antioxidant selects antioxidant 1010;

Embodiment 2

[0041] Example 2: A solvent-resistant polyphenylene ether composition prepared from the following components in parts by weight: 105 parts of PPO (with an intrinsic viscosity of 38 cm3 / g), 30 parts of SAN, 15 parts of a compatibilizer, and 0.8 parts of Antioxidant, 0.5 part lubricant.

[0042] The compatibilizer is SEBS-g-MAH;

[0043] The antioxidant is 2,6-di-tert-butyl-4-methylphenol plus phosphite synergistic antioxidant;

Embodiment 3

[0045] Example 3: A solvent-resistant polyphenylene ether composition prepared from the following components in parts by weight: 100 parts of PPO (with an intrinsic viscosity of 38 cm3 / g), 35 parts of SAN, 10 parts of a compatibilizer, 20 parts of Toughening agent, 0.8 parts of antioxidant, 0.5 parts of lubricant, 20 parts of flame retardant.

[0046] The compatibilizer is SEBS-g-MAH;

[0047] The toughening agent is SEBS;

[0048] The antioxidant is selected from antioxidant 1076;

[0049] The lubricant is selected from montan wax;

[0050] The flame retardant is tricresyl phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com