A kind of straw decomposing agent and its preparation method and application

A straw decomposing agent and straw technology are applied in the field of straw decomposing agents, which can solve the problems of long fermentation time and the like, and achieve the effects of good effect, fast decomposing speed and reducing diseases, insects and weeds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

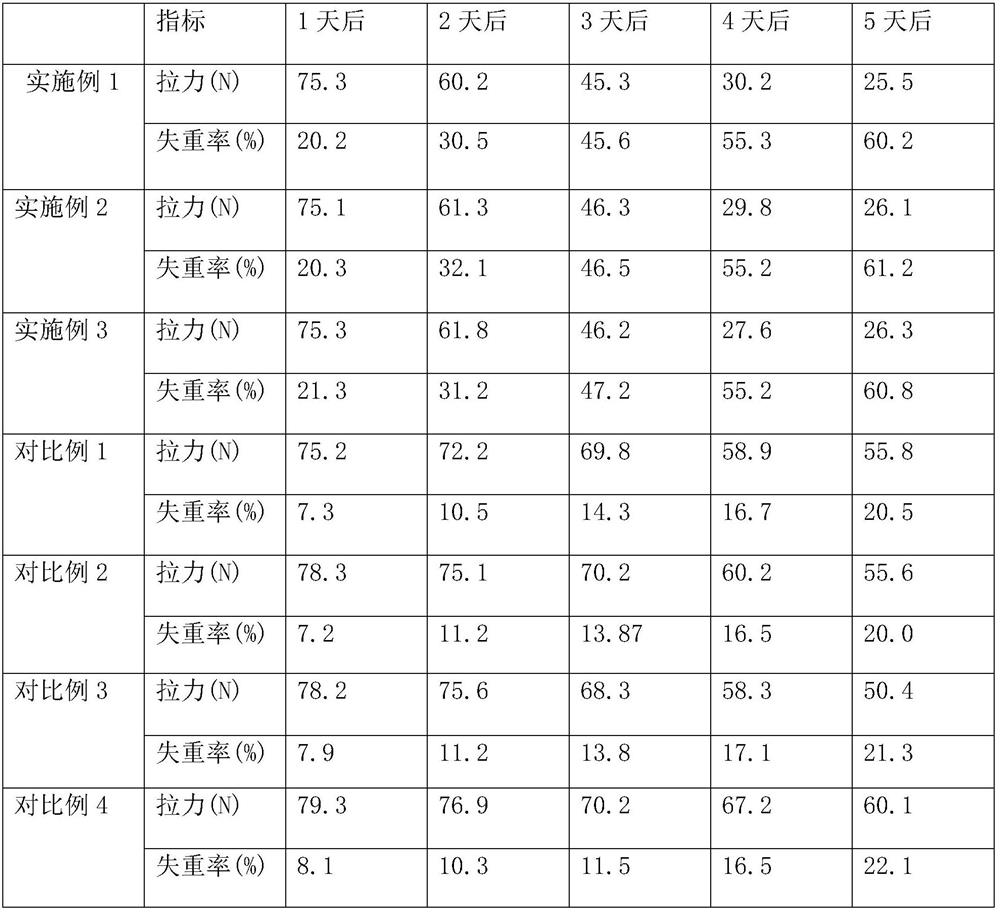

Embodiment 1

[0055] Preparation of Aspergillus niger agent:

[0056] (1) Inoculate the Aspergillus niger bacterial strain on the solid PDA medium plate, activate and cultivate at 37°C until the Aspergillus niger spores are covered with two-thirds of the medium plate;

[0057] (2) Scrape off the Aspergillus niger spores growing on the PDA medium plate, add sterile water to prepare the spore concentration of not less than 1.5×10 3 cfu / ml of Aspergillus niger spore suspension;

[0058] (3) The Aspergillus niger spore suspension was inoculated into the sporulation medium at a volume-to-mass ratio of 1:300, the thickness of the sporulation medium was 2 cm, and the sporulation was induced by constant temperature culture at 25°C for 7 days:

[0059] (4) pulverize the spore-forming medium together with the produced Aspergillus niger spores to 20 mesh, then freeze to -15° C., and vacuum dry to a water content of 6% to obtain an Aspergillus niger inoculum.

[0060] Preparation of Trichoderma virid...

Embodiment 2

[0081] Preparation of Aspergillus niger agent:

[0082] (1) Inoculate the Aspergillus niger bacterial strain on the solid PDA medium plate, activate and cultivate at 37°C until the Aspergillus niger spores are covered with two-thirds of the medium plate;

[0083] (2) Scrape off the Aspergillus niger spores growing on the PDA medium plate, add sterile water to prepare the spore concentration of not less than 1.5×10 3 cfu / ml of Aspergillus niger spore suspension;

[0084] (3) The Aspergillus niger spore suspension was inoculated into the sporulation medium at a volume-to-mass ratio of 1:300, the thickness of the sporulation medium was 5 cm, and the sporulation was induced by constant temperature culture at 40°C for 20 days:

[0085] (4) pulverize the sporulation medium together with the produced Aspergillus niger spores to 60 mesh, then freeze to -15° C., and vacuum dry to a water content of 7% to obtain an Aspergillus niger inoculum.

[0086] Preparation of Trichoderma viride...

Embodiment 3

[0107] Preparation of Aspergillus niger agent:

[0108] (1) Inoculate the Aspergillus niger bacterial strain on the solid PDA medium plate, activate and cultivate at 37°C until the Aspergillus niger spores are covered with two-thirds of the medium plate;

[0109] (2) Scrape off the Aspergillus niger spores growing on the PDA medium plate, add sterile water to prepare the spore concentration of not less than 1.5×10 3 cfu / ml of Aspergillus niger spore suspension;

[0110] (3) The Aspergillus niger spore suspension was inoculated into the sporulation medium at a volume-to-mass ratio of 1:300, the thickness of the sporulation medium was 3 cm, and the sporulation was induced by constant temperature culture at 30°C for 15 days:

[0111] (4) pulverize the sporulation medium together with the produced Aspergillus niger spores to 40 mesh, then freeze to -15° C., and vacuum dry to a water content of 6.5% to obtain an Aspergillus niger inoculum.

[0112] Preparation of Trichoderma viri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com