A kind of preparation method of ecological anti-hair loss rabbit skin

A technology for preventing hair loss and rabbit skin, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, tanning treatment, etc., can solve the problem of rabbit skin waterproof performance Good, easy to shed hair and other problems, to avoid industrial salt pollution, enhance softness, and strong binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

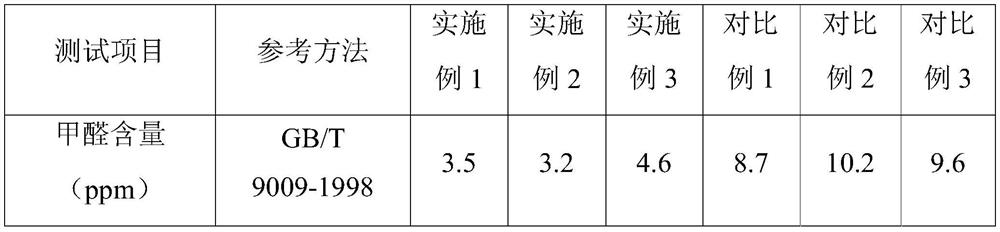

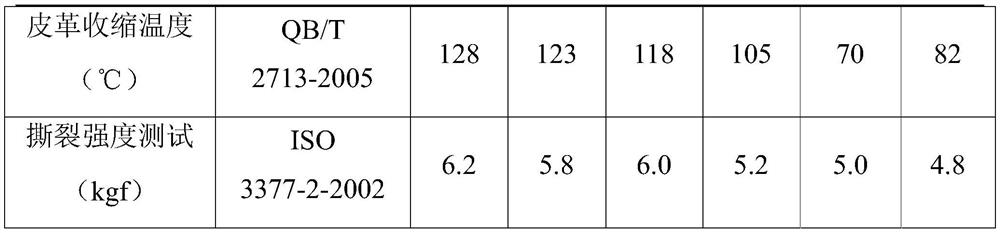

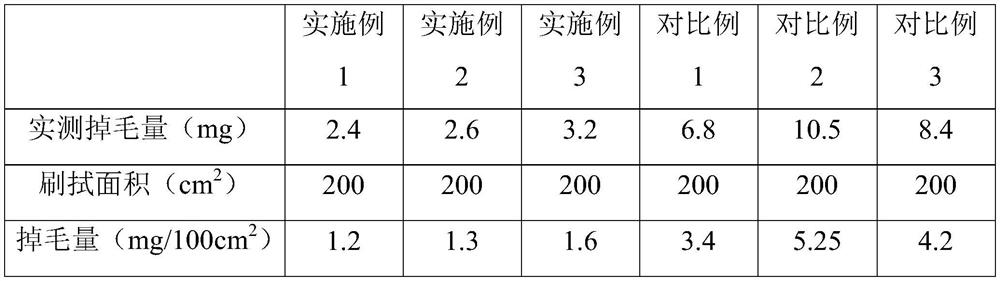

Examples

Embodiment 1

[0039] A kind of preparation method of ecological anti-shedding rabbit skin, is characterized in that, comprises the following steps:

[0040] (1) Immersion

[0041] Put the rabbit skin in a mixed solution including water, salt, glutaraldehyde and preservative DL503, soak it 8 times, each time for 30min; the final concentration of glutaraldehyde in the mixed solution is 0.5mL / L; the final concentration of table salt is 30g / L, the Baume degree is 2.0; the final concentration of the preservative DL503 is 0.1mL / L; the water temperature is 26°C;

[0042] (2) soreness

[0043] Use sulfuric acid with a concentration of 0.7mL / L and sodium bisulfite with a concentration of 0.3g / L to soak the soaked rabbit skin 5 times, 50min each time;

[0044] (3) Detumescence and degreasing

[0045] Use a mixture of sodium sulfate and salt with a weight ratio of 1:1 to mix with the rabbit skin treated with soreness, and then let it stand overnight; then place it in a degreasing solution, soak it ...

Embodiment 2

[0056] A kind of preparation method of ecological anti-shedding rabbit skin, is characterized in that, comprises the following steps:

[0057] (1) Immersion

[0058]Put the rabbit skin in a mixture of salt, glutaraldehyde and preservatives, soak it 8 times, 30min each time; the final concentration of glutaraldehyde in the mixture is 0.1mL / L; the final concentration of table salt is 18g / L ; The final concentration of preservative DL503 is 0.1mL / L.

[0059] (2) soreness

[0060] Use sulfuric acid with a concentration of 0.8mL / L and sodium bisulfite with a concentration of 0.5g / L to soak the soaked rabbit skin 5 times, 50min each time;

[0061] (3) Detumescence and degreasing

[0062] Use a mixture of sodium sulfate and salt with a weight ratio of 1:1 to mix with the rabbit skin treated with sore swelling, and then let it stand overnight; then place it in a degreasing solution, soak it for 30 minutes, and then dehydrate and shake it dry;

[0063] (4) Soften

[0064] Mix red ...

Embodiment 3

[0072] A kind of preparation method of ecological anti-shedding rabbit skin, is characterized in that, comprises the following steps:

[0073] (1) Immersion

[0074] The rabbit skin is placed in the mixed solution that comprises salt, glutaraldehyde and preservative, soaks 8 times, each time 40min; The final concentration of glutaraldehyde in the described mixed solution is 0.4mL / L; The final concentration of table salt is 22g / L; the final concentration of preservative DL50 is 0.3mL / L;

[0075] (2) soreness

[0076] Use sulfuric acid with a concentration of 0.8mL / L and sodium bisulfite with a concentration of 0.3g / L to soak the soaked rabbit skin 5 times, each time for 30 minutes;

[0077] (3) Detumescence and degreasing

[0078] Use a mixture of sodium sulfate and salt with a weight ratio of 1:1 to mix with the rabbit skin treated with soreness, and then let it stand overnight; then place it in a degreasing solution, soak it for 60 minutes, and then dehydrate and shake it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com