Conductive flocking roller and preparation method thereof

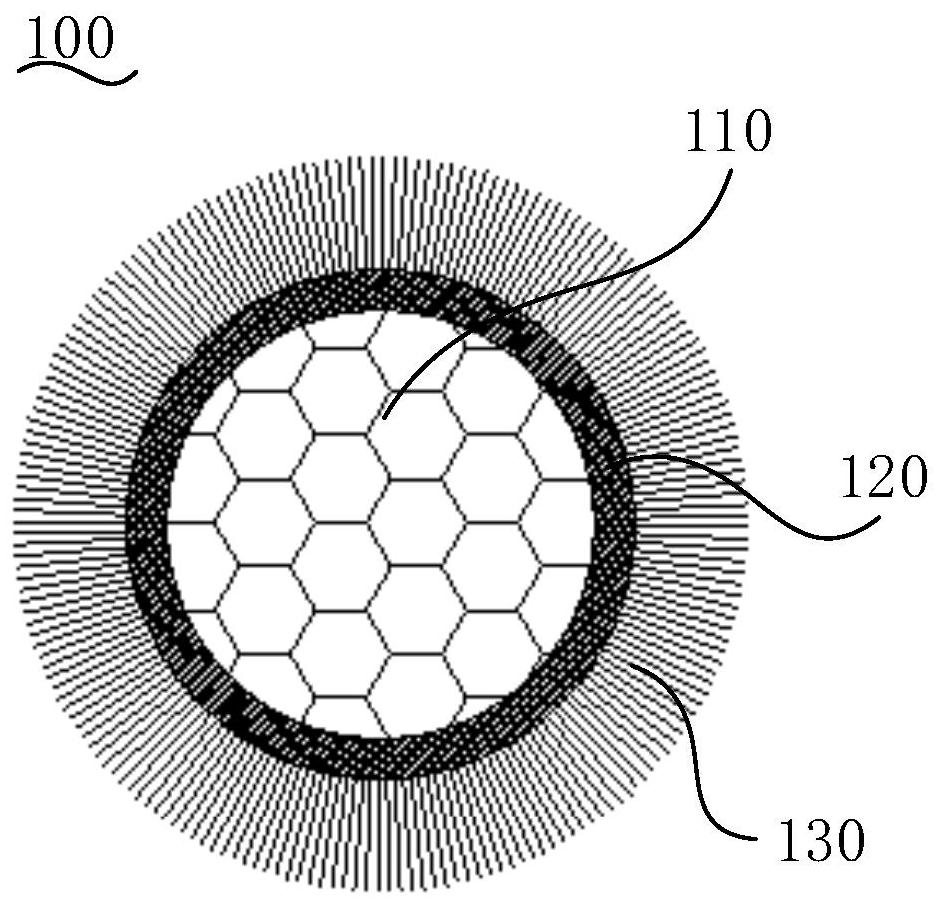

A flocking and conductive medium technology, applied in the field of conductive flocking rollers and their preparation, can solve the problems of uneven conductive resistance and hair loss, and achieve excellent adhesion, reduced hair loss, and good resistance uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

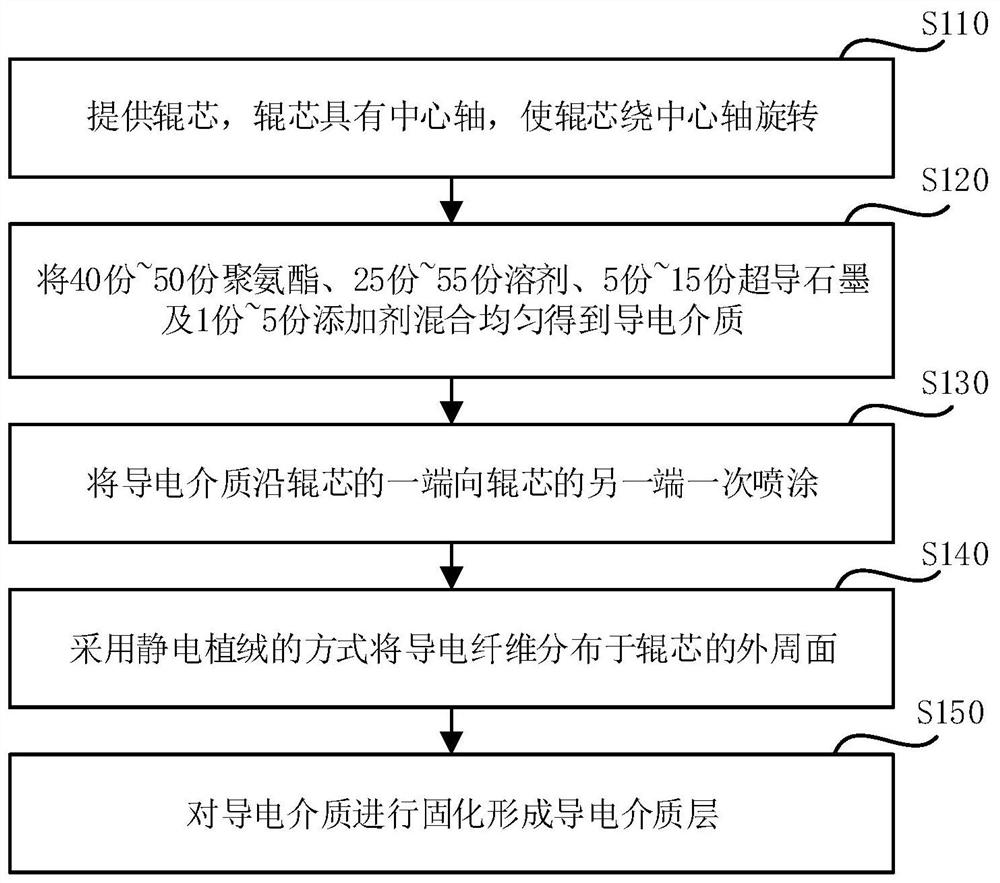

[0043] see figure 2 , the preparation method of the conductive flocking roller of an embodiment, comprises the following steps:

[0044] S110. Provide a roll core, the roll core has a central axis, and the roll core is rotated around the central axis.

[0045] In one embodiment, the rotation speed of the roller core around the central axis is 80rpm-120rpm.

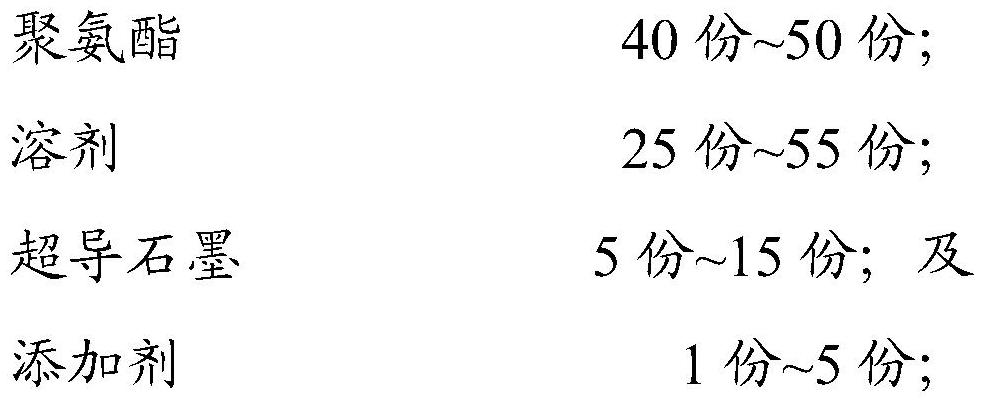

[0046] S120, uniformly mixing 40-50 parts of polyurethane, 25-55 parts of solvent, 5-15 parts of superconducting graphite and 1-5 parts of additives to prepare a conductive medium.

[0047] In one of the embodiments, the solvent is selected from at least one of butyl acetate, ethyl acetate and propyl acetate; the additive is selected from propylene glycol methyl ether acetate, methyl isobutyl ketone and dibasic acid ester (DBE) at least one of the

[0048] S130, sequentially spraying the conductive medium along one end of the roller core to the other end of the roller core.

[0049] In one embodiment, a spray gun is u...

Embodiment 1

[0059] A roll core is provided, the roll core is a stainless steel roll core, and the diameter of the roll core is 10mm. Prepare a conductive medium, the conductive medium includes 40 parts of polyurethane, 25 parts of butyl acetate, 5 parts of superconducting graphite and 1 part of propylene glycol methyl ether acetate; wherein, the specific gravity of polyurethane is 1.005, the viscosity is 100cps, and the superconducting graphite The particle size of superconducting graphite is 250 μm, and the conductivity of superconducting graphite is 5.8. Rotate the roller core around the central axis at a speed of 80rpm, and use a spray gun to spray the conductive medium along one end of the roller core to the other end of the roller core at a running speed of 60mm / s, spraying 4 rounds, so that the conductive medium is on the roller The outer peripheral surface of the core is evenly distributed. Electrostatic flocking is used to distribute conductive fibers on the outer peripheral surf...

Embodiment 2

[0061] A roll core is provided, the roll core is an aluminum roll core, and the diameter of the roll core is 12mm. Prepare conductive medium, conductive medium comprises 50 parts of polyurethane, 55 parts of butyl acetate, 15 parts of superconducting graphite and 5 parts of propylene glycol methyl ether acetate; Wherein, the specific gravity of polyurethane is 0.95, and viscosity is 400cps, superconducting graphite The particle size of superconducting graphite is 300 μm, and the conductivity of superconducting graphite is 7. Rotate the roller core around the central axis at a speed of 120rpm, and use a spray gun to spray the conductive medium back and forth along one end of the roller core to the other end of the roller core at a running speed of 70mm / s, spraying 6 rounds, so that the conductive medium is on the roller The outer peripheral surface of the core is evenly distributed. Electrostatic flocking is used to distribute conductive fibers on the outer peripheral surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com