Milling-free in-situ cold recycled asphalt pavement maintenance method

A technology of asphalt pavement and cold recycling, applied in the field of asphalt pavement maintenance, can solve the problems of high construction difficulty, closed for 2 hours or more, and does not improve the bearing capacity of the pavement structure, and achieves the effect of repairing aging asphalt and enhancing waterproofing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

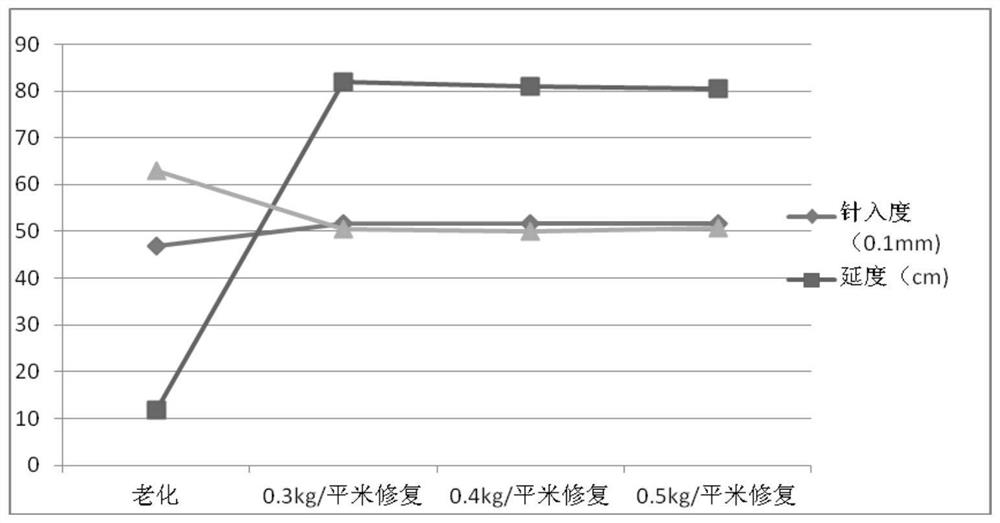

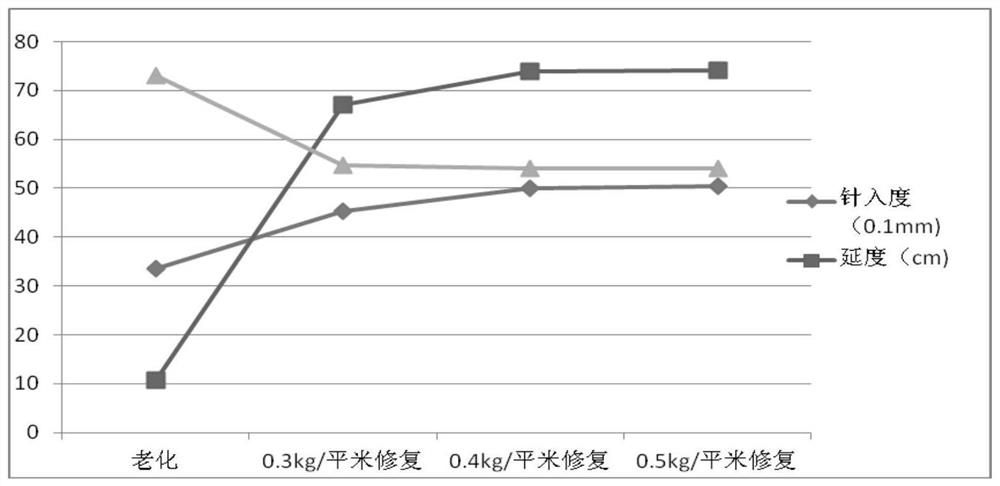

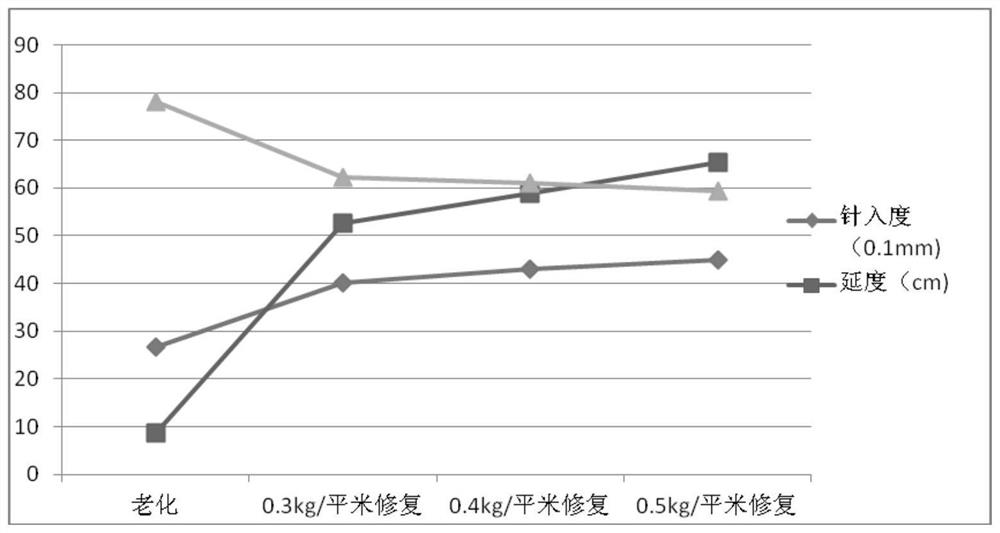

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0025] A kind of in-situ cold regeneration asphalt pavement maintenance method without milling of the present invention comprises the following steps:

[0026] 1) select the asphalt reduction regeneration agent prepared by refining naphthenic crude oil, and mix and stir evenly with water in proportion;

[0027] 2) Pour the evenly stirred asphalt reduction rejuvenation agent into the storage tank of the special distribution vehicle;

[0028] 3) After the special distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com