Self-lubricating contact type composite sealing device for high-temperature part of gas turbine engine

A gas turbine and composite sealing technology, which is applied in the lubrication of engines, turbines/propulsion devices, engine components, etc., can solve problems such as poor sealing structure effects, achieve stable sealing, improve sealing effects, and increase transmission volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

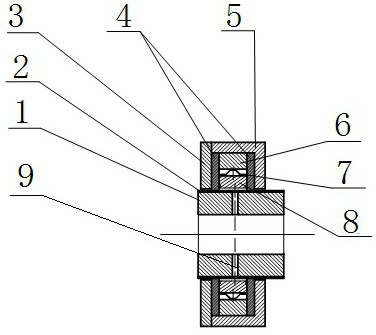

[0028] Embodiment 1, a self-lubricating contact type composite sealing device for a high temperature part of a gas turbine engine, such as figure 1 As shown, including the inner sealing ring 1 arranged on the turbine shaft of the gas turbine engine, when the turbine shaft moves, the inner sealing ring 1 will move synchronously with the turbine shaft. Since the turbine shaft is a high-temperature component of the gas turbine engine, the turbine shaft is deformed by heat and recovers when cooled. Both the turbine shaft and the inner sealing ring 1 will undergo reciprocating axial deformation, that is, the inner sealing ring 1 will undergo cyclic expansion and contraction.

[0029] The outer periphery of the sealed inner ring 1 is provided with a compression assembly, and the compression assembly is provided with a fingertip seal ring 4 and an annular graphite lubricant 8, and the inner wall of the fingertip seal ring 4 is slidingly fitted with the outer wall of the sealed inner r...

Embodiment 2

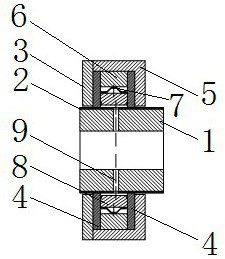

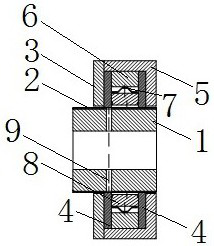

[0036] Embodiment 2, a self-lubricating contact type composite sealing device for a high temperature part of a gas turbine engine, such as Figure 5 and 6 As shown, the graphite lubricating element 8 includes several graphite blocks interlocked with each other, which not only ensures the reliability of the friction between the graphite lubricating element 8 and the fingertip sealing ring 4, but also effectively reduces the air leakage area and improves the sealing effect. Under the action of the elastic support 7, the multi-stage combined graphite lubricating part 8 is automatically attached to the center, the graphite powder is shed by friction, and the graphite powder is transferred to the fingertip seal through the working mode of the sealing inner ring 1 cyclic expansion and contraction. The ring 4 forms a self-lubricating integrated design in the working area of the fingertip sealing ring 4 and the sealing inner ring 1.

[0037] The present invention fully realizes the...

Embodiment 3

[0041] Embodiment 3, a self-lubricating contact type composite sealing device for a high-temperature part of a gas turbine engine, when used for a gas turbine engine with a turbine shaft with an internal bleed air function, such as figure 1 As shown, the side wall of the sealed inner ring 1 is provided with an air-introducing hole 9 leading to the graphite lubricating member 8, which can form an air-tight structure between the graphite lubricating member 8 and the sealed inner ring 1, which is conducive to reducing leakage. The air area is beneficial to increase the amount of friction and shedding of ultra-fine graphite powder, which is conducive to increasing the transfer amount of graphite powder to the contact position between the fingertip seal ring 4 and the inner seal ring 1 at both ends, and can also reduce the graphite lubrication of the multi-stage combination in the free floating state Part 8 interferes with the sealing inner ring 1. When the gas turbine engine is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com