Wireless low-power-consumption furnace wall temperature measuring device

A temperature measurement device, low power consumption technology, applied in the field of detection, can solve problems such as long inspection period and insecurity, achieve low power consumption, ensure integrity, and achieve the effect of data continuity and analyzability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further description will be given below in conjunction with the accompanying drawings and embodiments.

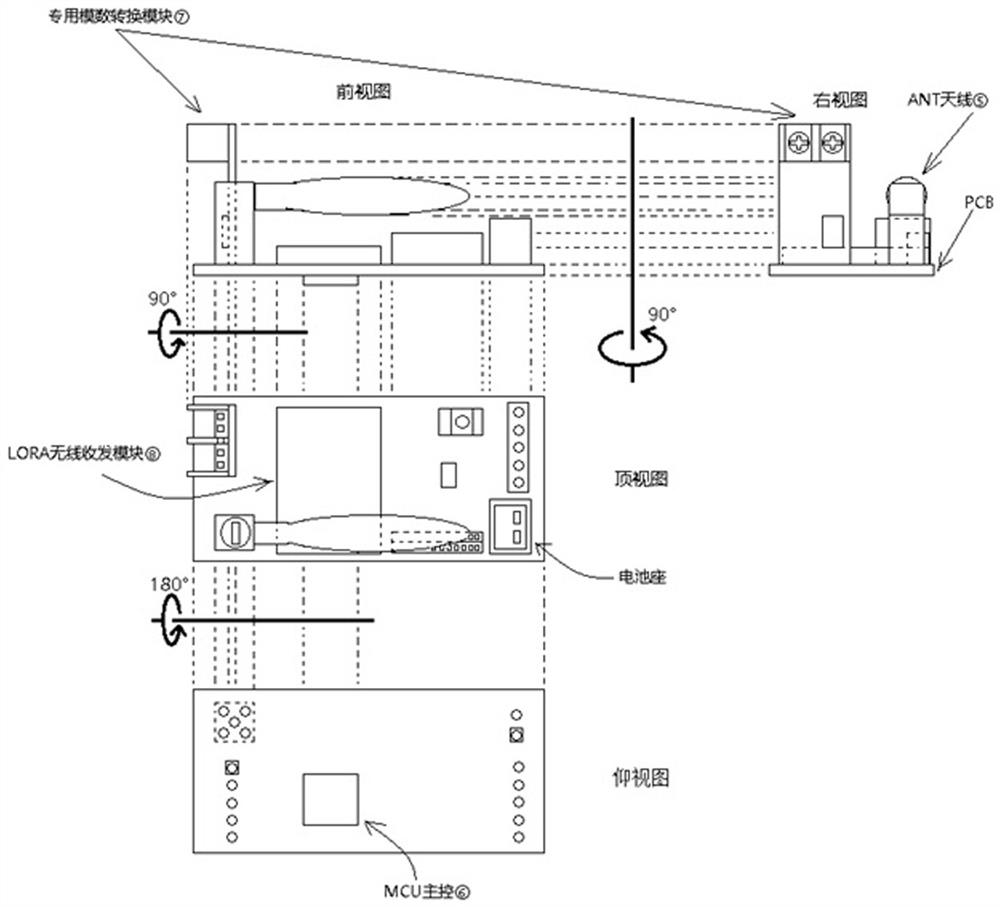

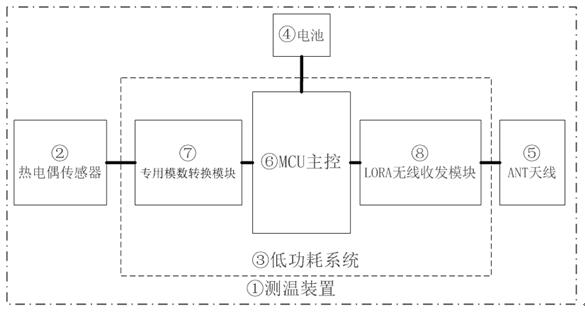

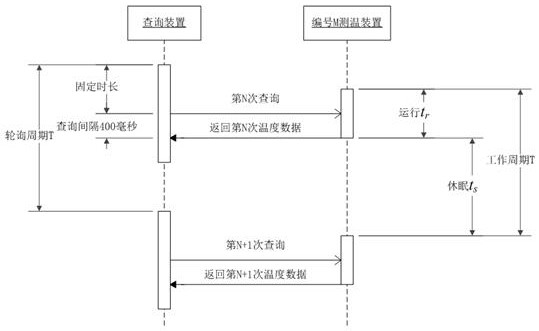

[0023] figure 1 Shown: wireless low power consumption furnace wall temperature measurement device, including special temperature measurement device ①, communication protocol, low power consumption control sequence, special temperature measurement device includes thermocouple sensor ②, low power consumption system ③, industrial lithium battery ④, ANT antenna ⑤; low-power system board includes low-power processor ⑥, dedicated analog-to-digital conversion module ⑦, LORA wireless transceiver module ⑧. The system interface connection relationship is: the galvanic sensor ② is connected to the connection terminal of the dedicated analog-to-digital conversion module ⑦, the dedicated analog-to-digital conversion module ⑦ is connected to the MCU main control ⑥ through soldering, and the LORA wireless transceiver module ⑧ is connected to the MCU main control through soldering. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com