Narrow-band metasurface device

A metasurface, device technology, applied in instruments, optical components, optics, etc., can solve problems such as wide bandwidth, low efficiency, and filtering secondary peaks of the spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

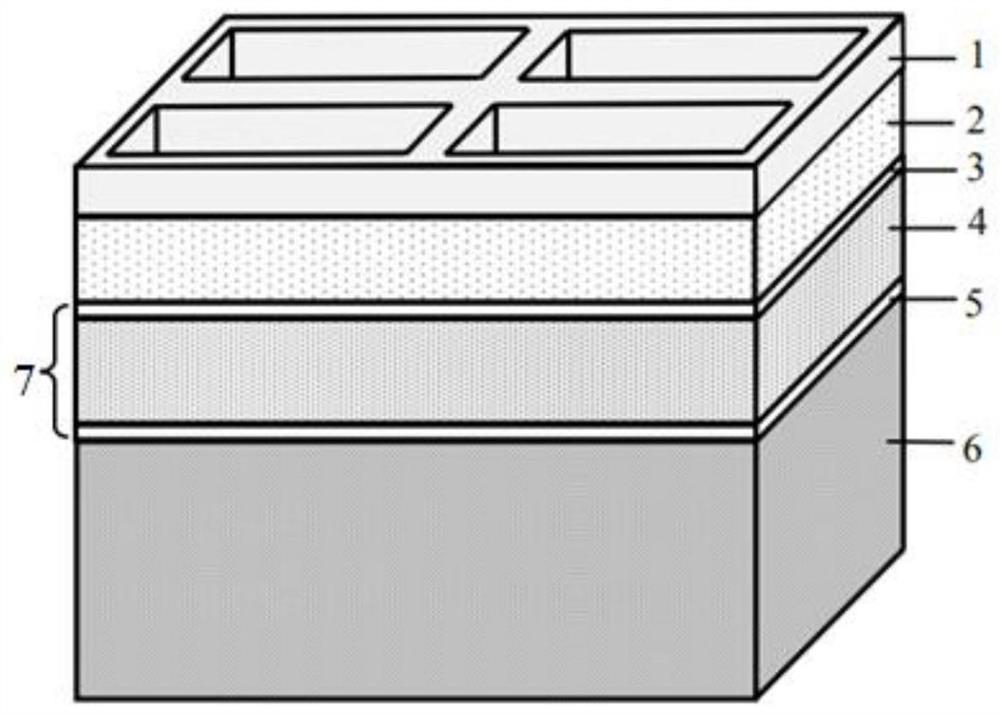

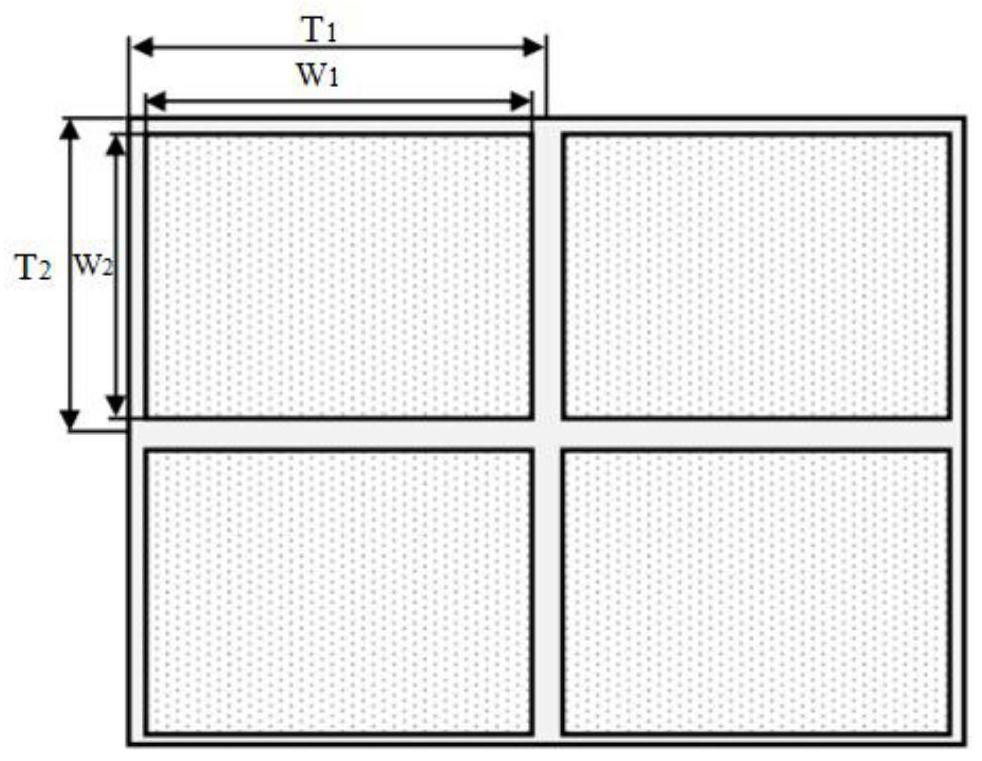

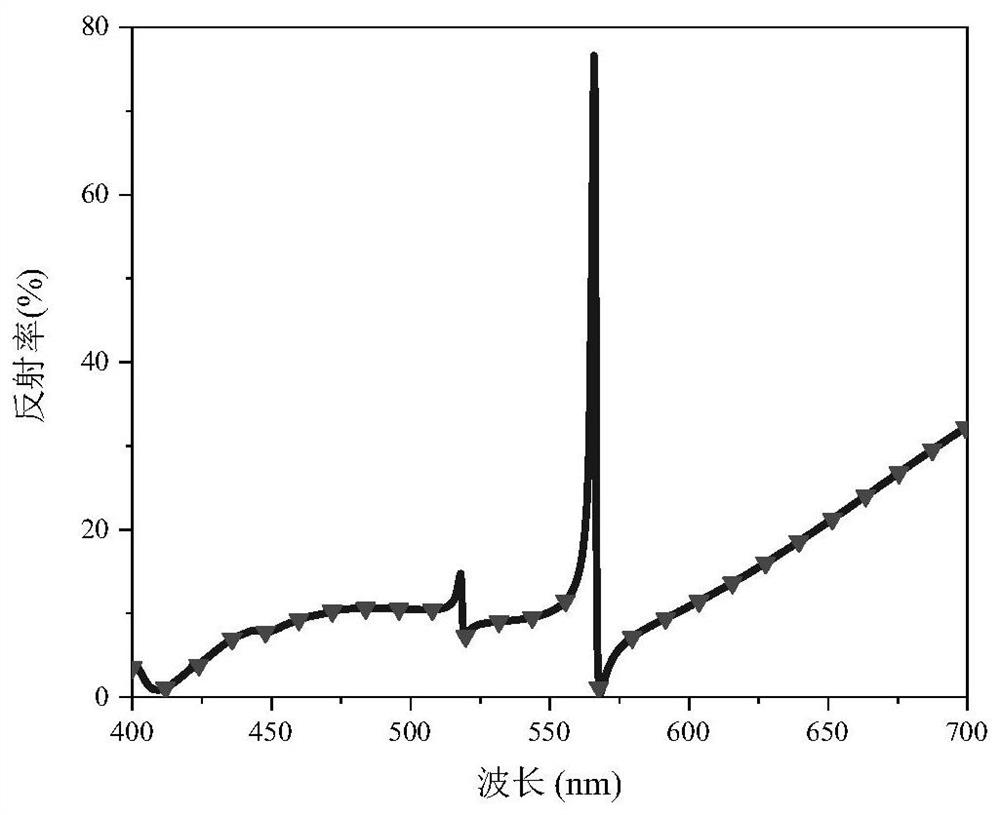

[0035] The structure of the narrow-band metasurface device in this embodiment is as figure 1 with figure 2 Shown. The two-dimensional top view of the metasurface element and the metal groove element in the groove antenna metasurface layer 1 are both square, namely T 1 = T 2 , W 1 =W 2 . The material of the supersurface layer of the groove antenna is Ag, and the period is T 1 = T 2 =340nm, W 1 =W 2 =306nm, the aperture ratio at this time is 0.81, and the thickness of the groove antenna supersurface layer 1 is 80nm. The thickness of the buffer medium layer 2 is 60 nm, and the material is magnesium fluoride. The thickness of the first transparent electrode layer 3 and the second transparent electrode layer 5 is 5nm, and the material is In 2 O 3 -SnO 2 . The thickness of the adjustable dielectric layer 4 is 120 nm, and the material is organic crystal DAST. The material of the base layer 6 is SiO 2 , The thickness is 300nm. In this embodiment, the refractive index of the adjust...

Embodiment 2

[0037] The structure of the narrow-band metasurface device in this embodiment is as figure 1 with figure 2 Shown. The two-dimensional top view of the metasurface element and the metal groove element in the groove antenna metasurface layer 1 are both square, namely T 1 = T 2 , W 1 =W 2 . The material of the supersurface layer of the groove antenna is Ag, and the period is T 1 = T 2 =340nm, W 1 =W 2 =306nm, the aperture ratio at this time is 0.81, and the thickness of the groove antenna supersurface layer 1 is 80nm. The thickness of the buffer medium layer 2 is 60 nm, and the material is magnesium fluoride. The thickness of the transparent electrode layer is 5nm, and the material is In 2 O 3 -SnO 2 . The thickness of the adjustable dielectric layer 4 is 120 nm, and the material is organic crystal DAST. The material of the base layer 6 is SiO 2 , The thickness is 300nm. In this embodiment, a voltage is applied to the transparent electrode layer, and the refractive index of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fwhm | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com