Method for preparing black garlic

A technology for black garlic and garlic, applied in the field of preparing black garlic, can solve the problems of high nutritional value of black garlic, long fermentation time and short fermentation time of black garlic, and achieve the effects of speeding up the fermentation cycle, excellent health care effect and short fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] According to a kind of preferred embodiment of the present invention, described method for preparing black garlic, this method comprises the following steps:

[0043] (1) pick out the garlic without damage, no scar, and no mildew, and clean and dry it to obtain the garlic to be processed;

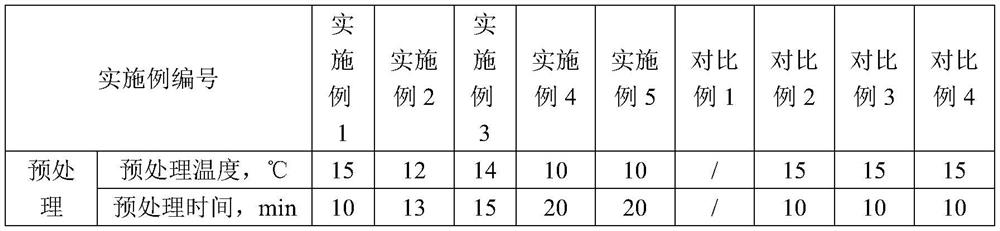

[0044] (2) Mix the garlic to be processed with the black garlic solution obtained from step (5), and then perform pretreatment. The pretreatment conditions include: the pretreatment temperature is 10-15°C, and the pretreatment pressure is 50°C. -80MPa, pretreatment time is 5-20min;

[0045] (3) The product obtained in step (2) is subjected to primary fermentation for 1.5-2.5 days at an air humidity of 60-70% RH and 40-55° C., and then incubated for 1-2 days;

[0046] The amount by weight ratio of the garlic to be processed to the black garlic solution obtained from step (5) is 1.5-6:1;

[0047] (4) Under the conditions of air humidity of 60-70% RH and 50-65°C, the product obtained ...

Embodiment 1

[0053] (1) pick out the garlic without damage, no scar, and no mildew, and clean and dry it to obtain the garlic to be processed;

[0054] (2) Mix the garlic to be processed with the black garlic solution obtained from step (5), and then perform pretreatment. The conditions of the pretreatment include: the pretreatment temperature is 15°C, the pretreatment pressure is 70MPa, the pretreatment The processing time is 10min; the amount by weight ratio of the garlic to be processed to the black garlic solution obtained from step (5) is 3:1;

[0055] (3) The product obtained in step (2) is subjected to primary fermentation for 2 days at an air humidity of 60% RH and 50° C., and then heat-preserved and fermented for 1.5 days;

[0056] (4) Under the condition of air humidity of 60%RH and 55°C, the product obtained in step (3) was subjected to secondary fermentation for 2 days, followed by heat preservation and fermentation for 1.5 days;

[0057] (5) Under the conditions of air humidi...

Embodiment 2

[0060] (1) pick out the garlic without damage, no scar, and no mildew, and clean and dry it to obtain the garlic to be processed;

[0061] (2) Mix the garlic to be processed with the black garlic solution obtained from step (5), and then perform pretreatment. The conditions of the pretreatment include: the pretreatment temperature is 12°C, the pretreatment pressure is 60MPa, the pretreatment The processing time is 13min; the amount by weight ratio of the garlic to be processed to the black garlic solution obtained from step (5) is 1.5:1;

[0062] (3) The product obtained in step (2) is subjected to primary fermentation for 1 day at an air humidity of 60% RH and 40° C., and then heat-preserved and fermented for 2 days;

[0063] (4) Under the conditions of air humidity of 60% RH and 60°C, the product obtained in step (3) was subjected to secondary fermentation for 1.5 days, and then incubated for 2 days;

[0064] (5) Under the condition of air humidity of 60% RH and 68° C., the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com