Waterproof wound cleaning device for surgery wound suture

A cleaning device and wound technology, applied in the field of cleaning devices, can solve the problems of affecting the surrounding environment, disinfectant water is easy to penetrate into the wound, etc., and achieve the effect of increasing the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

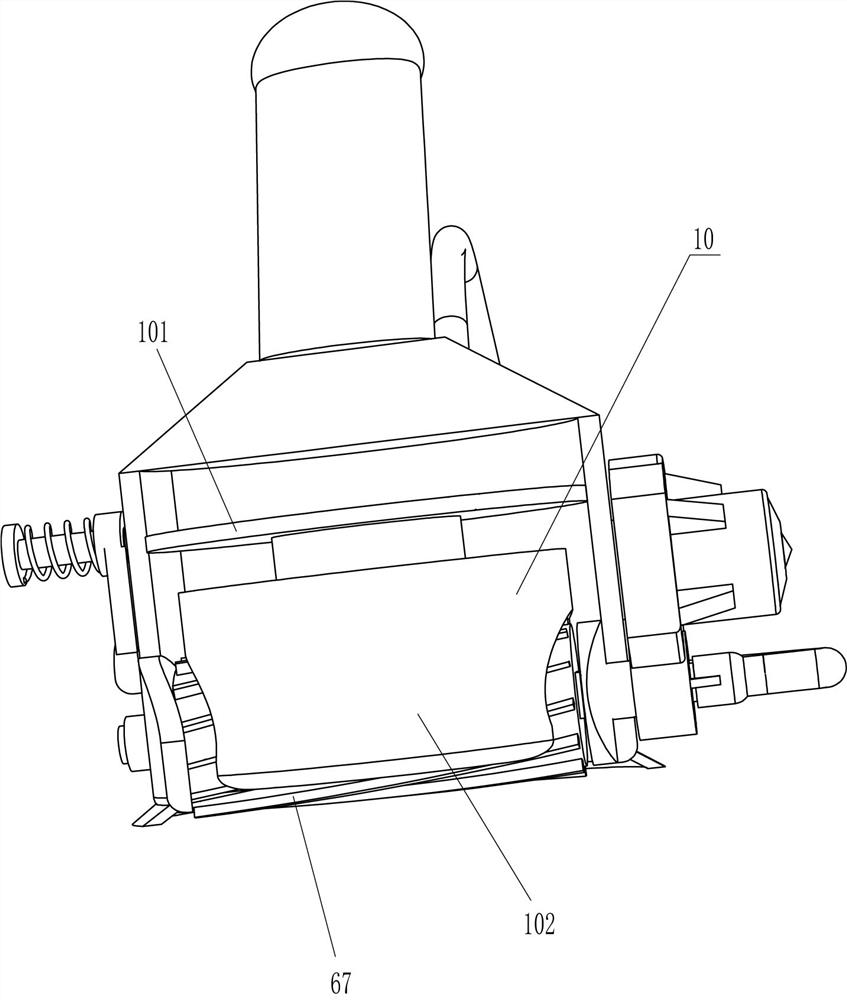

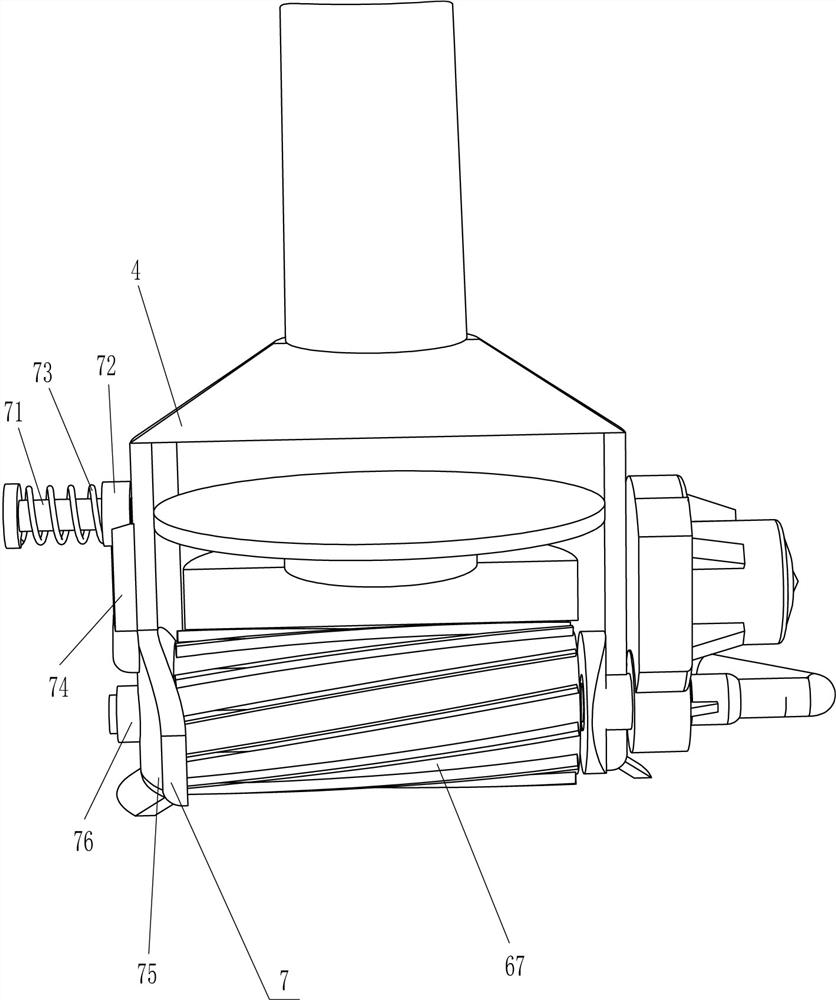

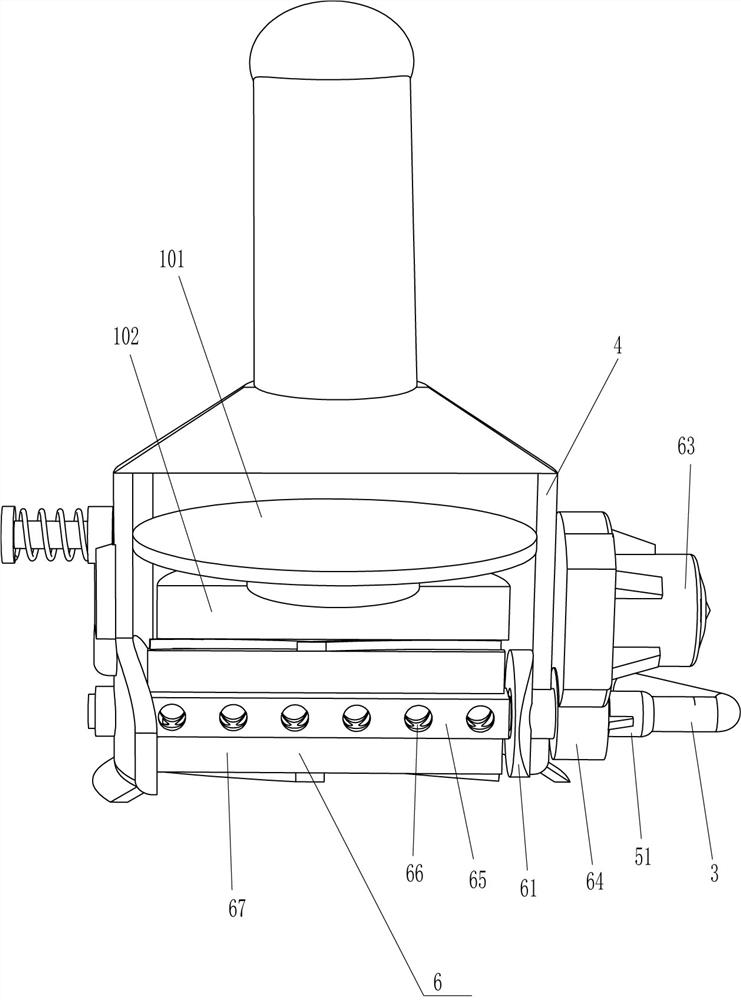

[0023] see Figure 1-Figure 4 , a kind of waterproof wound washer for suturing surgical wounds, comprising a liquid tank 1, a liquid pump 2, a liquid outlet pipe 3, a fixed cover 4, a handle 5, a hollow connecting pipe 51, a cleaning mechanism 6 and a fixing mechanism 7, the liquid tank 1 A liquid pump 2 is installed in the middle of the top, the liquid outlet end of the liquid pump 2 is connected with a liquid outlet pipe 3, the liquid outlet pipe 3 communicates with the liquid pump 2, the liquid inlet end of the liquid pump 2 is located in the liquid tank 1, and the liquid outlet pipe 3 ends The end is fixedly connected with a hollow connecting pipe 51, the hollow connecting pipe 51 communicates with the liquid outlet pipe 3, a fixed cover 4 is arranged behind the hollow connecting pipe 51, and a handle 5 is fixedly connected in the middle of the outer top of the fixed cover 4, and the handle 5 is arranged obliquely. Fixed cover 4 bottom is provided with cleaning mechanism 6...

Embodiment 2

[0030] see figure 1 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a waste liquid collection mechanism 8 is also included. The waste liquid collection mechanism 8 includes a collection box 81, a liquid suction pump 82 and a liquid inlet pipe 83, and the liquid tank 1, a collection box 81 is installed on the outer right side, and a liquid suction pump 82 is installed on the top of the collection box 81. The liquid outlet end of the liquid suction pump 82 is connected with a liquid inlet pipe 83. The tail end of the pipe 83 is connected in the middle of the upper right side of the fixed cover 4 , and the liquid inlet pipe 83 communicates with the fixed cover 4 .

[0031] When the medical staff moves the fixed cover 4 to make the sponge roller 67 clean around the wound, the liquid suction pump 82 can be started, and the liquid suction pump 82 operates to suck the waste liquid that occurs in the cleaning process into the liquid inlet...

Embodiment 3

[0033] see figure 1 , image 3 and Figure 5 , compared with embodiment 1 and embodiment 2, the main difference of this embodiment is that in this embodiment, an edge banding mechanism 9 is also included, and the edge banding mechanism 9 includes an arc-shaped rubber ring 91 and an arc-shaped sealing plate 92, and the matching plate The bottom of 75 is affixed with an arc-shaped sealing plate 92 , and the bottom of the fixed cover 4 is affixed with an arc-shaped rubber ring 91 , and the arc-shaped rubber ring 91 contacts and cooperates with the arc-shaped sealing plate 92 .

[0034] It also includes a diversion mechanism 10, the diversion mechanism 10 includes an isolation plate 101 and a filling block 102, the upper part of the inner surface of the fixed cover 4 is fixed with an isolation plate 101, and the center of the bottom of the isolation plate 101 is fixed with a filler block 102, and the filler block 102 Be positioned at sponge roller 67 tops and cooperate with it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com