Apparatus for a oxide powder

A technology for oxide powder and manufacturing equipment, applied in tin oxide, chemical/physical processes, gallium/indium/thallium compounds, etc., can solve the problems of reducing the characteristics of oxide powder and increasing the cohesion between powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

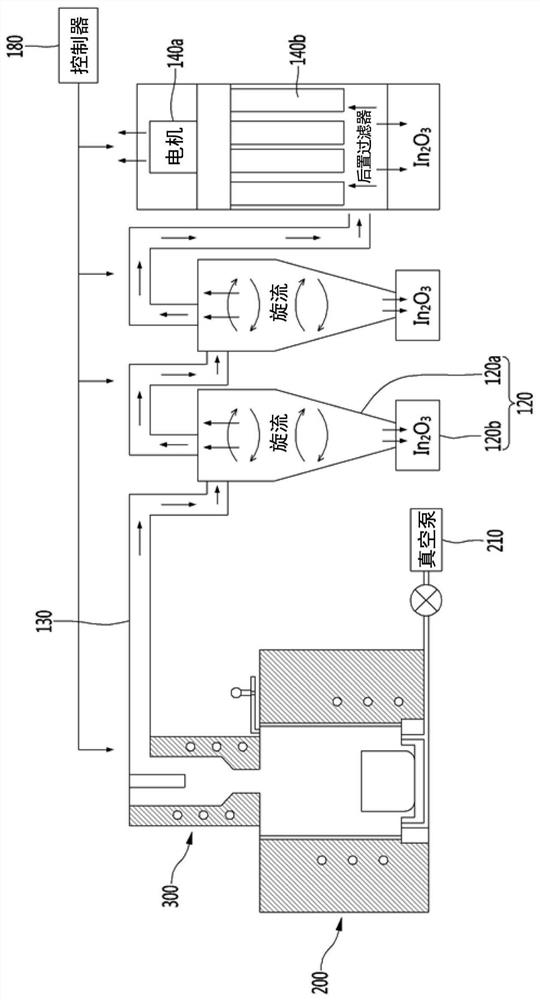

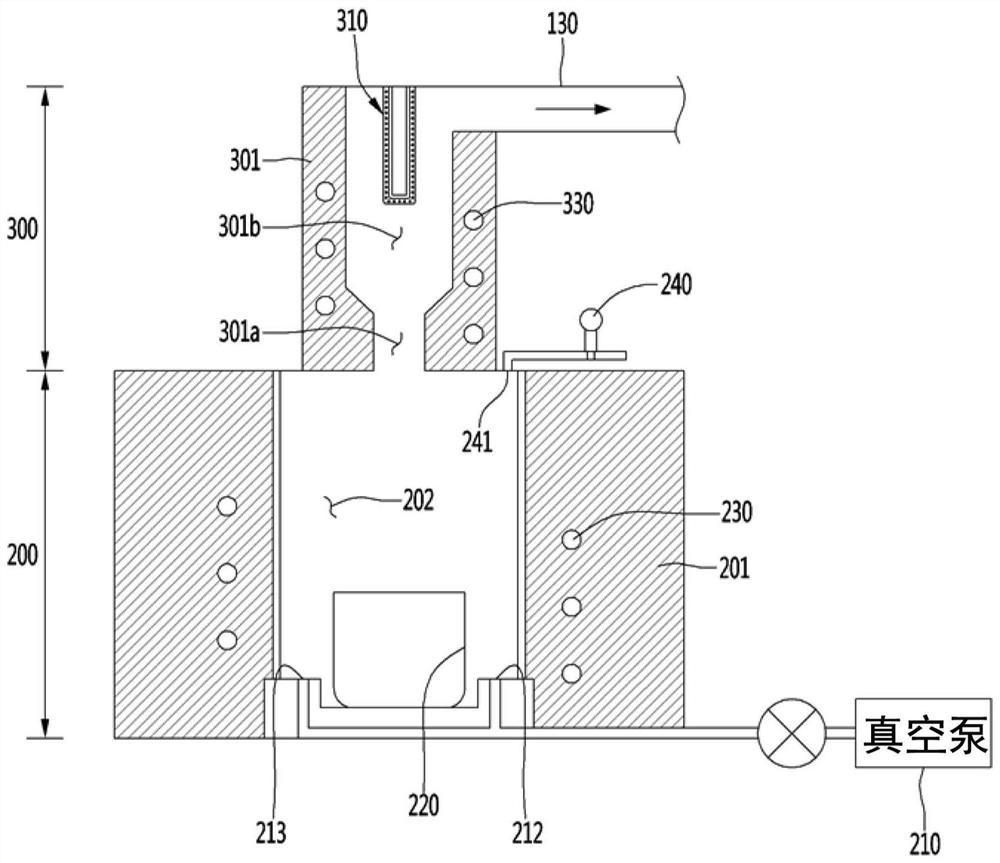

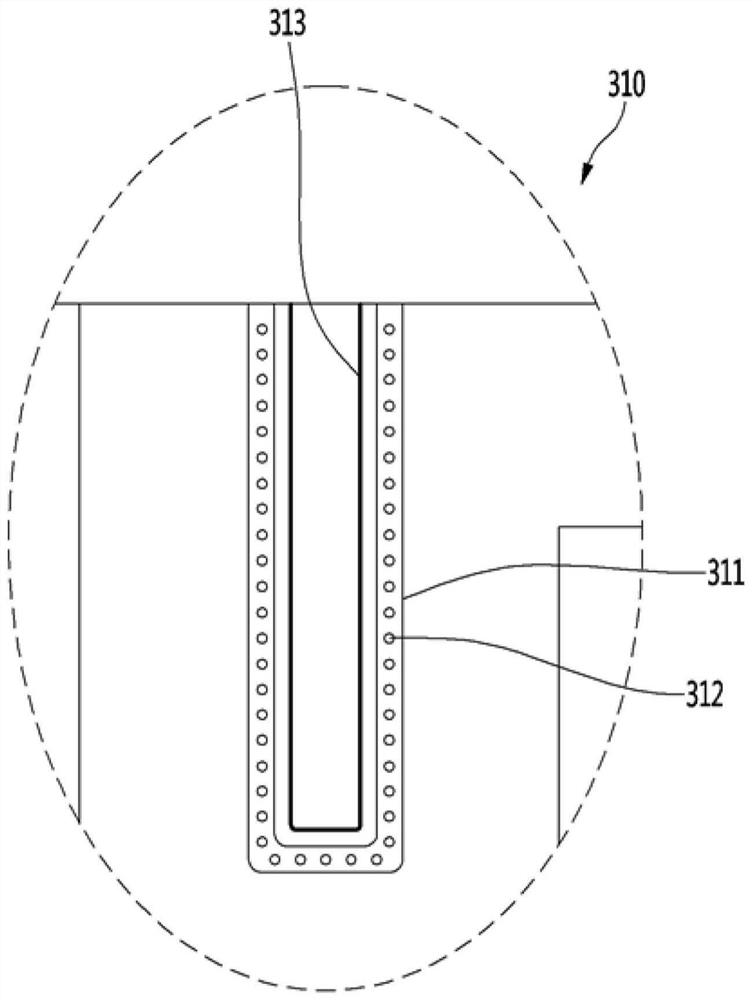

[0022] figure 1 It is a figure which shows the overall structure of the oxide powder manufacturing apparatus of this invention. refer to figure 1 , The oxide powder manufacturing device 100 of the present invention includes: an evaporation chamber 200, which heats a solid reaction substance to evaporate it into an oxide in a droplet state; an oxidation reaction chamber 300, which is arranged on the evaporation chamber 200 side, to pulverize the steam of the reaction substance generated in the evaporation chamber 200; the transfer pipe 130, used to move the powder generated in the oxidation reaction chamber 300; at least one trapping unit 120, used to Trapping of moving oxide powder.

[0023] The transfer pipe 130 is arranged between the oxidation reaction chamber 300 and the trapping unit 120, and in the case of a plurality of trapping units 120, the transfer pipe 130 is also arranged between the trapping units, The action of moving the oxide in the droplet state is thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com