Industrial multifunctional micro-channel reactor production system

A technology of microchannel reactors and channel reactors, which is applied in chemical/physical/physicochemical reactors, chemical instruments and methods, control/regulation processes, etc., and can solve the problems of skid-mounted microchannel reactor blanks and other issues , to achieve the effect of convenient installation and combination and high flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

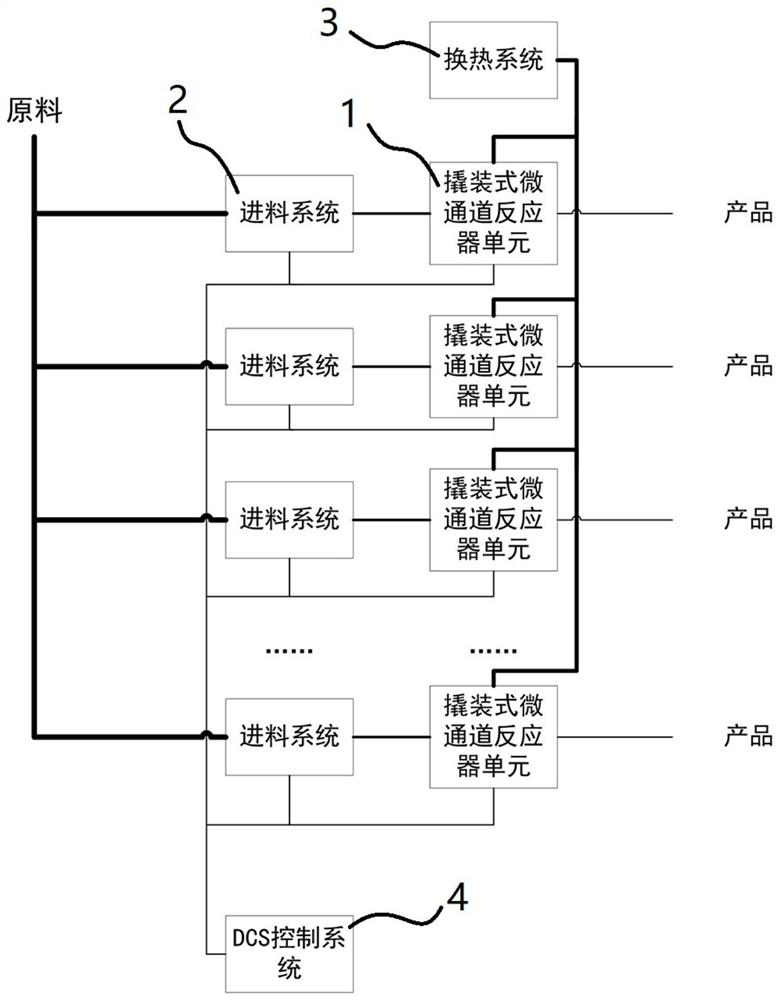

[0055] Such as figure 1 As shown, an industrial multifunctional microchannel reactor production system includes a skid-mounted microchannel reactor unit 1, a feed system 2, a heat exchange system 3 and a DCS control system 4:

[0056] Each skid-mounted microchannel reactor unit 1 is connected to an independent feed system 2;

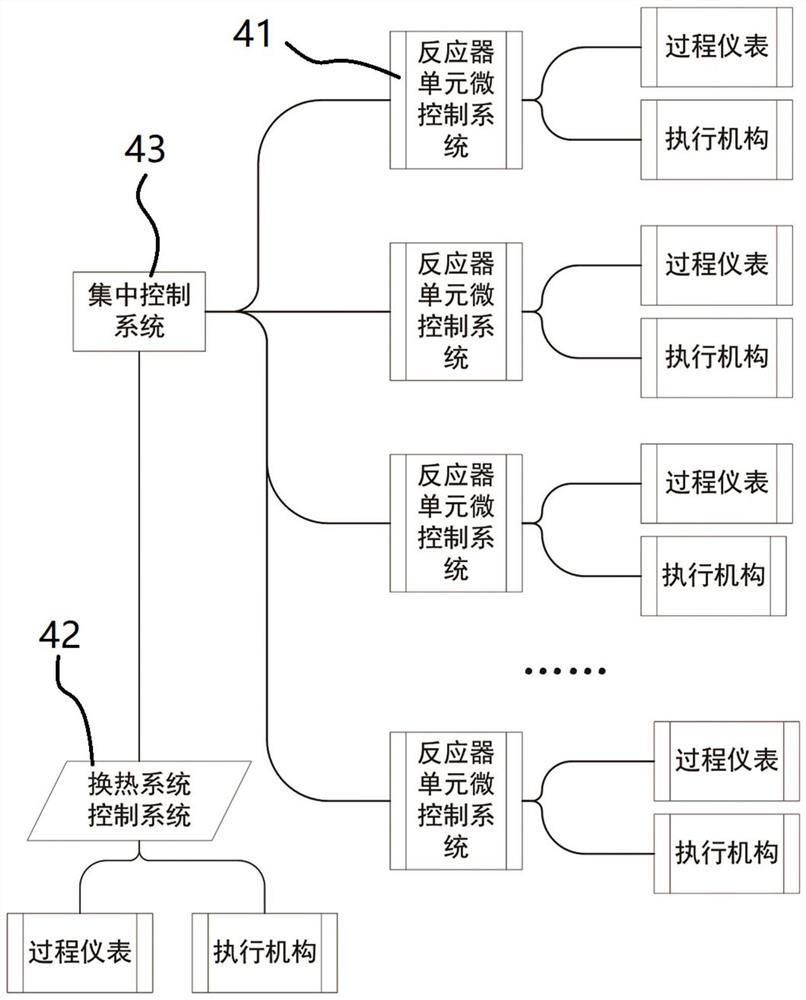

[0057] Such as figure 2 As shown, the DCS control system 4 includes a reactor unit micro control system 41, a heat exchange system control system 42 and a centralized control system 43, and the centralized control system 43 is remotely connected to the reactor unit micro control system 41 and the heat exchange system control system. The system 42 constitutes the DCS control system 4;

[0058] Such as figure 1 As shown, n (n >= 2) described skid-mounted microchannel reactor unit 1 and the independent feeding system 2 that it connects are arranged in parallel, and described skid-mounted microchannel reactor unit 1 connects heat exchange system 3, Toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com