Multi-material variable-stiffness structural efficient collaborative additive manufacturing method

A technology of additive manufacturing and variable stiffness, applied in the field of additive manufacturing, can solve the problems of low molding efficiency, high cost, difficult to prepare parts, etc., and achieve the effect of reducing production costs, reducing processing cycles, and improving the level of additive manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

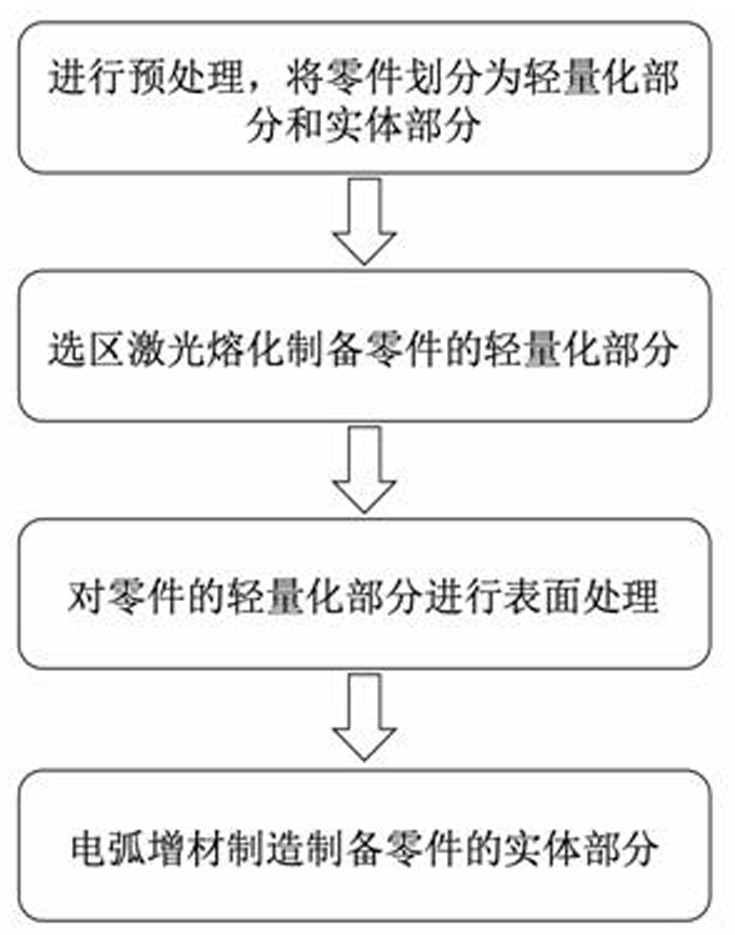

[0041] A multi-material, variable stiffness structure efficient collaborative additive manufacturing method, mainly comprising the following steps:

[0042]1) Use the 3D modeling software UG to construct a 3D model of multi-material and variable stiffness structures, use the simulation software ANSYS to analyze the stress of the 3D structural model, obtain stress distribution diagrams in different regions, and optimize the structural model. Parts are divided into lightweight parts with a porous lattice structure and solid parts for rapid fabrication.

[0043] 2) Use the selective laser melting molding process to prepare lightweight parts with a porous lattice structure. Select 316 stainless steel powder as the raw material for the selective laser melting molding and load it into the powder feeding device. The particle size of the powder is 25 μm. Set the molding process parameters. The preheating temperature of the molding substrate of the melting molding equipment is set to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com