Scanning galvanometer

A scanning galvanometer and lens technology, applied in the field of scanning galvanometers, can solve problems such as difficulty in further improvement, and achieve the effects of reducing the difficulty of debugging, reducing strength requirements, and improving scanning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

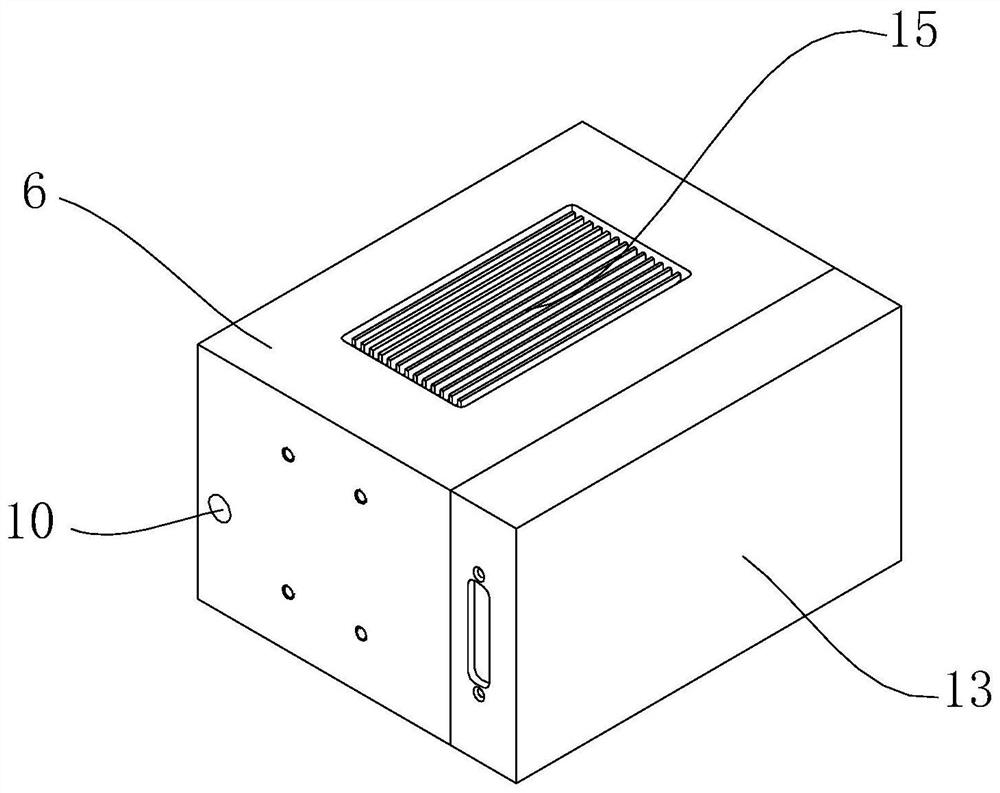

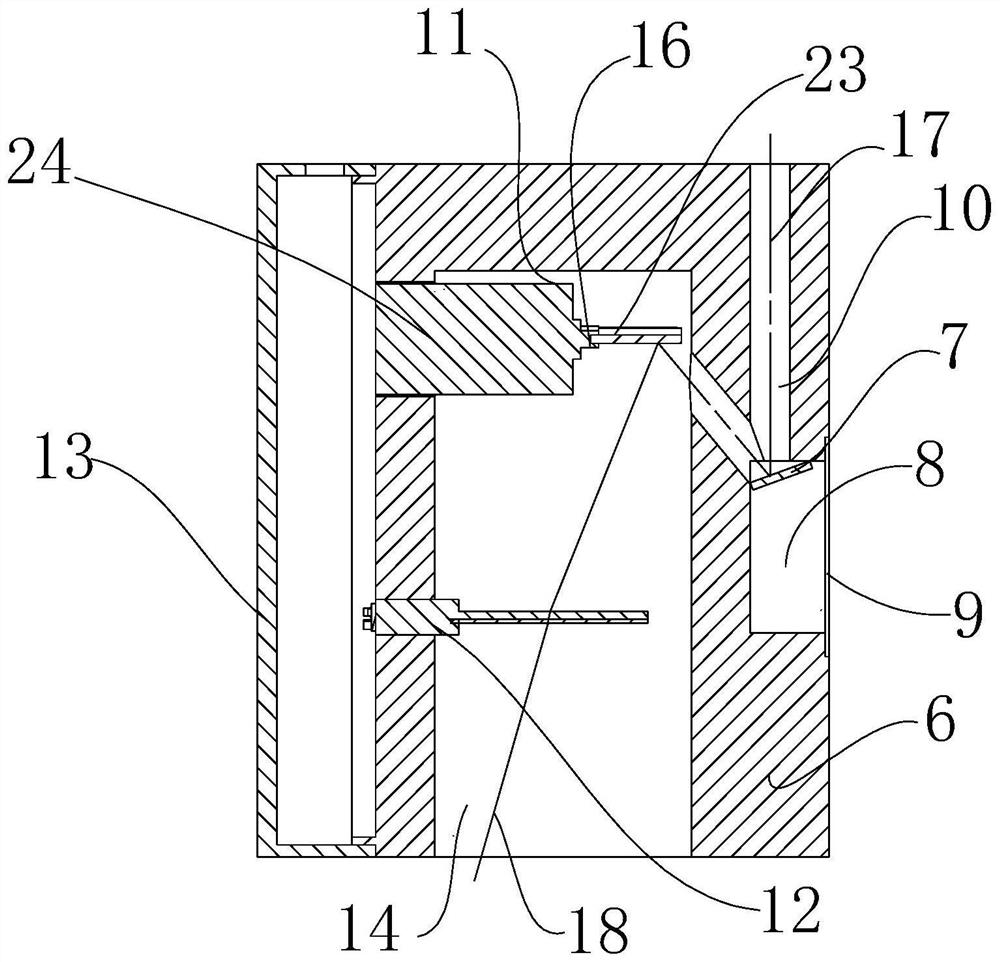

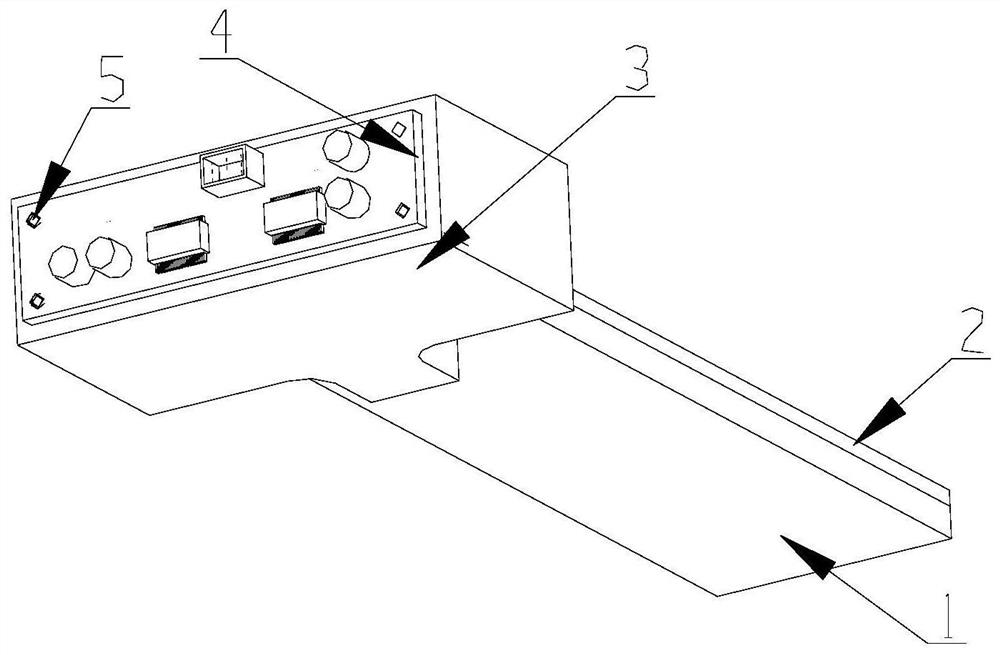

[0040] Embodiments of the present invention are as follows, with reference to Figure 1~4 , a scanning vibrating mirror, including a housing, an X-axis vibrating mirror assembly 11, a Y-axis vibrating mirror assembly 12 and a mirror 7, the housing is provided with a light inlet 10, a light outlet 14 and a mirror cavity 8, the The reflector 7 is arranged in the reflector cavity 8, the light entrance hole 10, the reflector cavity 8 and the light exit hole 14 are connected, and the X-axis vibrating mirror assembly 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com