Intelligent pneumatic chuck and laser cutting machine

A technology of intelligent pneumatic card and cylinder, which is applied to laser welding equipment, instruments, measuring devices, etc., can solve the problem that pneumatic chucks cannot be applied, and achieve the effect of improving laser cutting efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

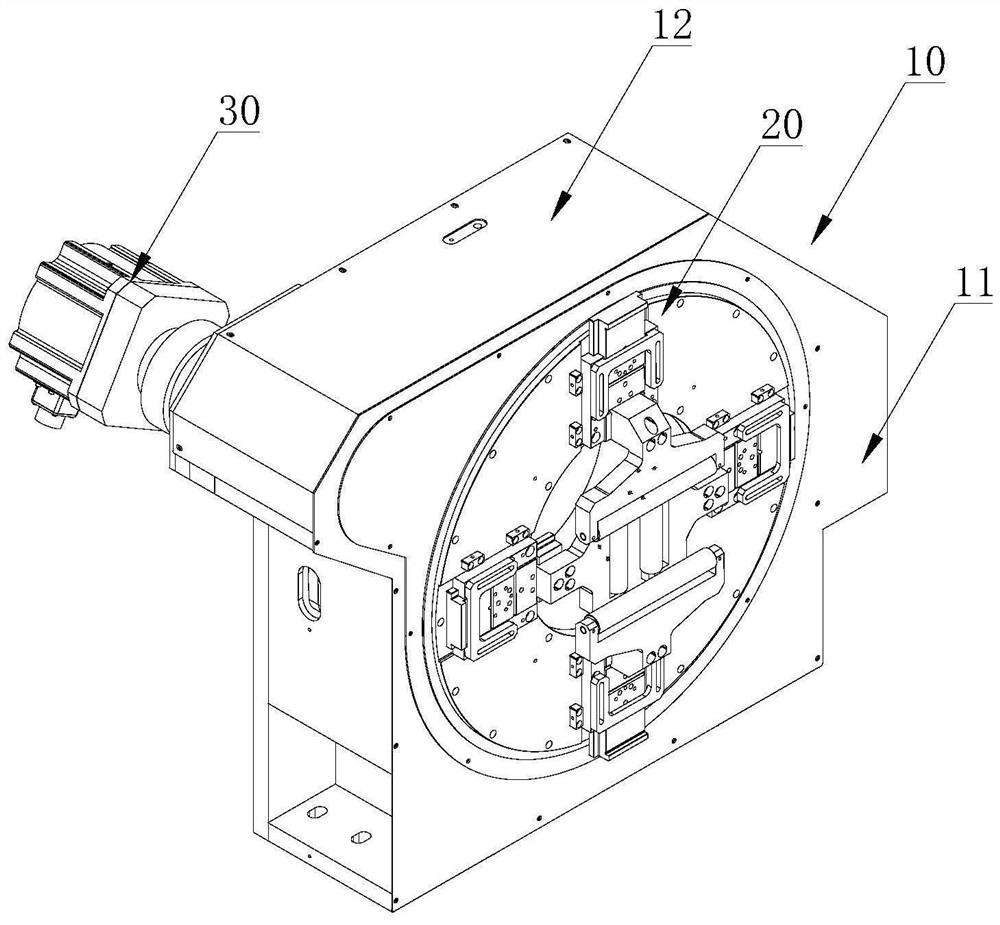

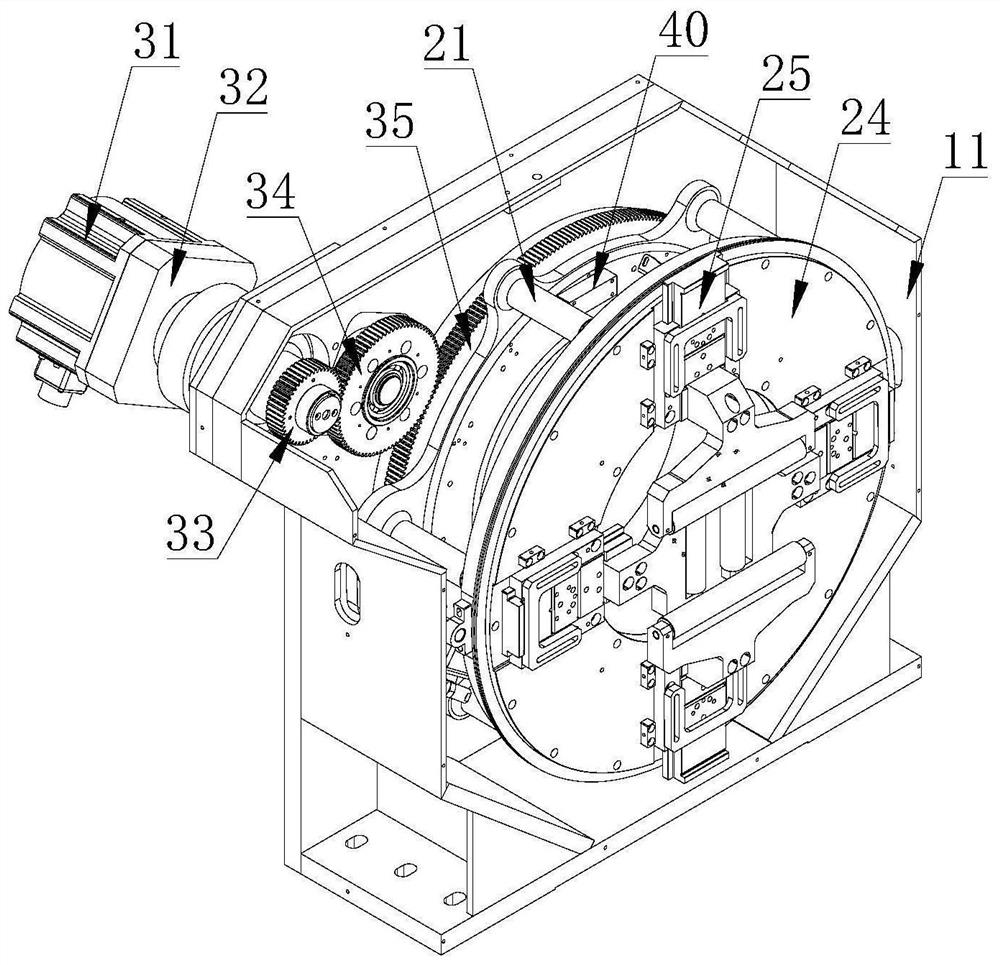

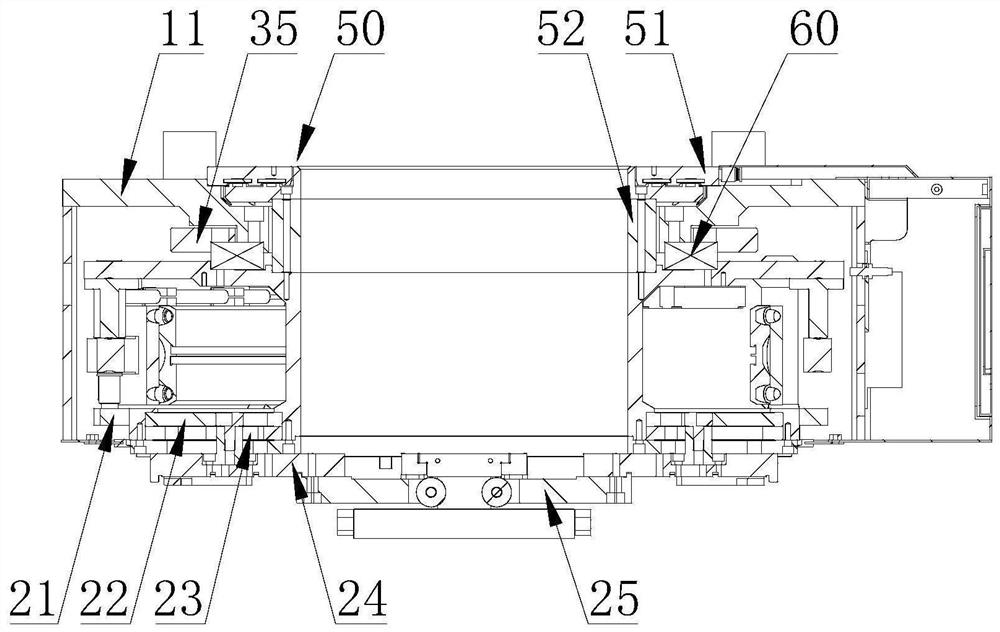

[0035] refer to Figure 1-13 , the present embodiment discloses an intelligent pneumatic chuck, including a mounting housing 10, a rotating body assembly 20 and a driving device 30; The fixed connection forms a hollow cavity that can accommodate the rotating body assembly 20, and the front and rear ends of the mounting base 11 are provided with through holes for pipes to pass through. The rotating body assembly 20 is arranged in the installation housing 10, and the driving device 30 At the rear end of the installation housing 10, and the driving device 30 is connected to the rotating body assembly 20, the rotating body assembly 20 includes a rotating base 21, a cylinder 26 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com