Series welding machine for preventing welding strip from being twisted and method thereof

A technology of string welding machine and welding ribbon, applied in the device for preventing the distortion of the welding ribbon, preventing the distortion of the welding ribbon, and preventing the twisting of the welding ribbon in the field of string welding machine, which can solve the problems of cracking of the battery cell and avoid welding. together, close fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

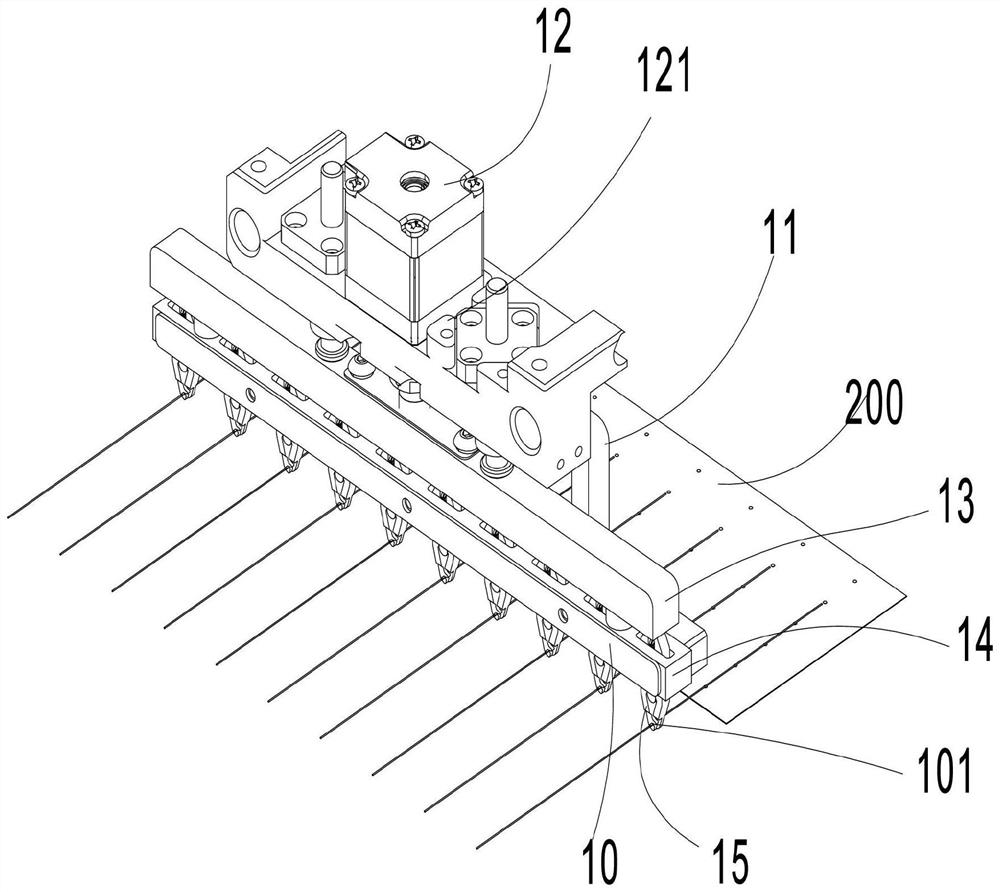

[0031] Combine below Figure 1 to Figure 11 Embodiments of the present invention will be described in detail.

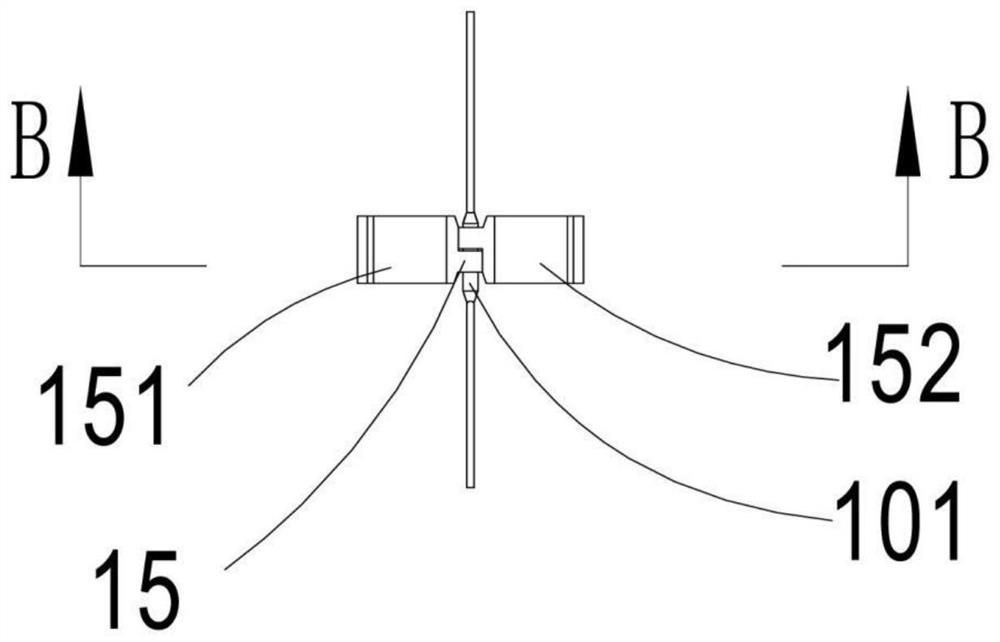

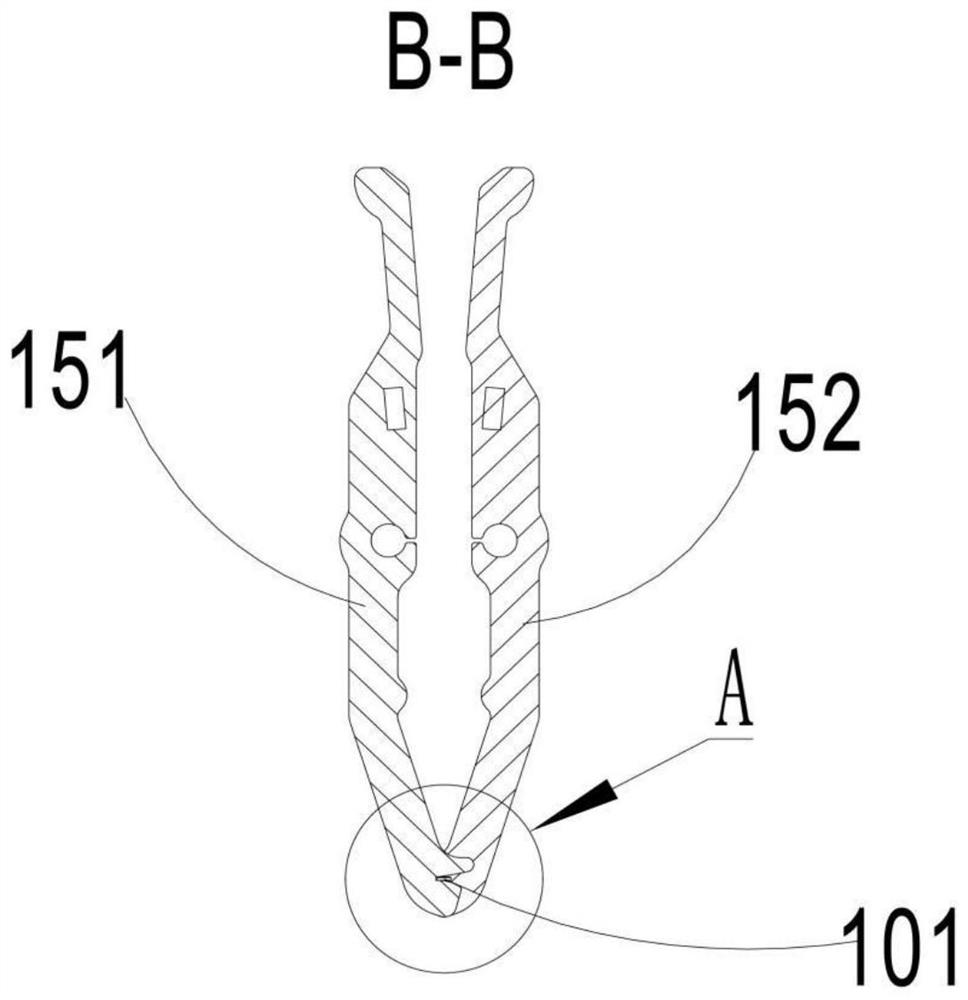

[0032] figure 1 The composition structure of the device for preventing the twisting of the ribbon on the stringer is shown, the device includes: a return mechanism 10 for embracing the flat section 101 of the weld ribbon; it is arranged on the upper part of the return mechanism 10 for driving the return Mechanism 10 corrects the lifting mechanism 12 for the welding strip; the fixing seat 11 for installing the correcting mechanism 10 and the lifting mechanism 12; wherein, when the normalizing mechanism 10 performs correction, it forms a flat section that only allows the welding strip The clamping hole 253 through which 101 passes, the shape of the clamping hole 153 is similar to the shape of the section of the flat section 101 of the welding ribbon, and the width and height of the clamping hole 153 are slightly larger than the width and thickness of the flat section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com