Robot joint closed-loop braking device

A technology of robot joints and braking devices, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of heavy load of the robot itself, poor reliability of the braking mechanism, increased power consumption, etc., and achieve a compact overall structure layout, easy assembly, The effect of reducing gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

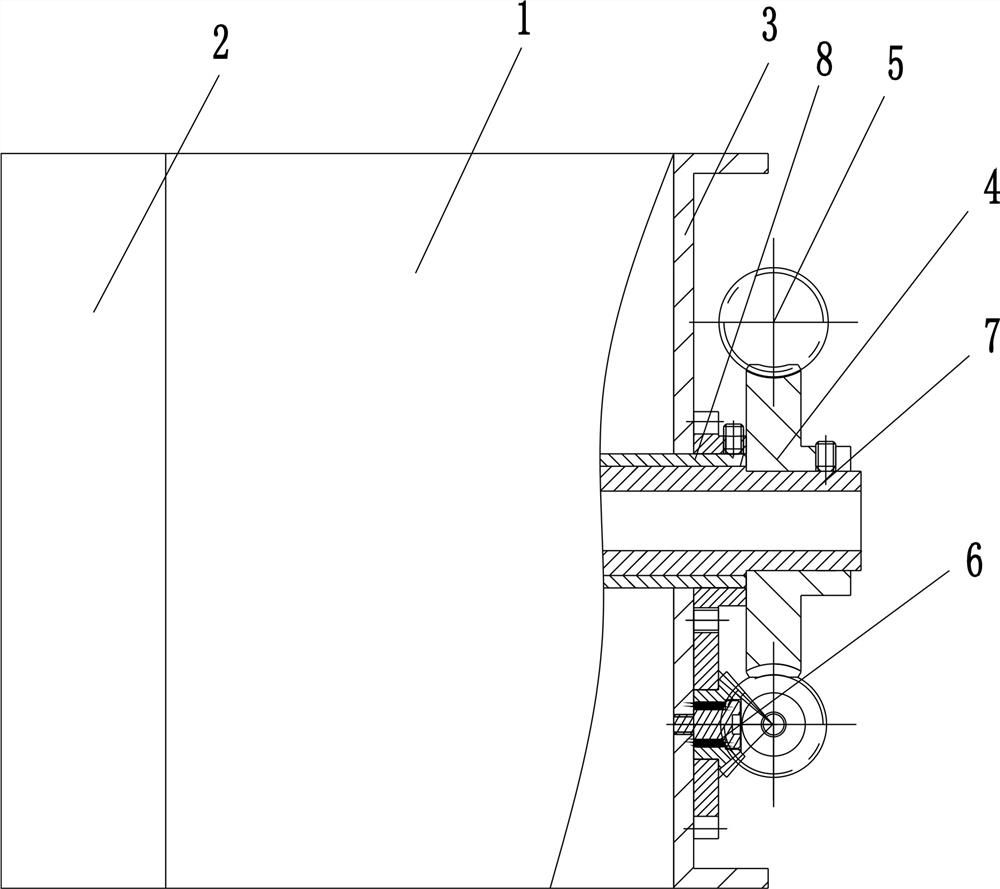

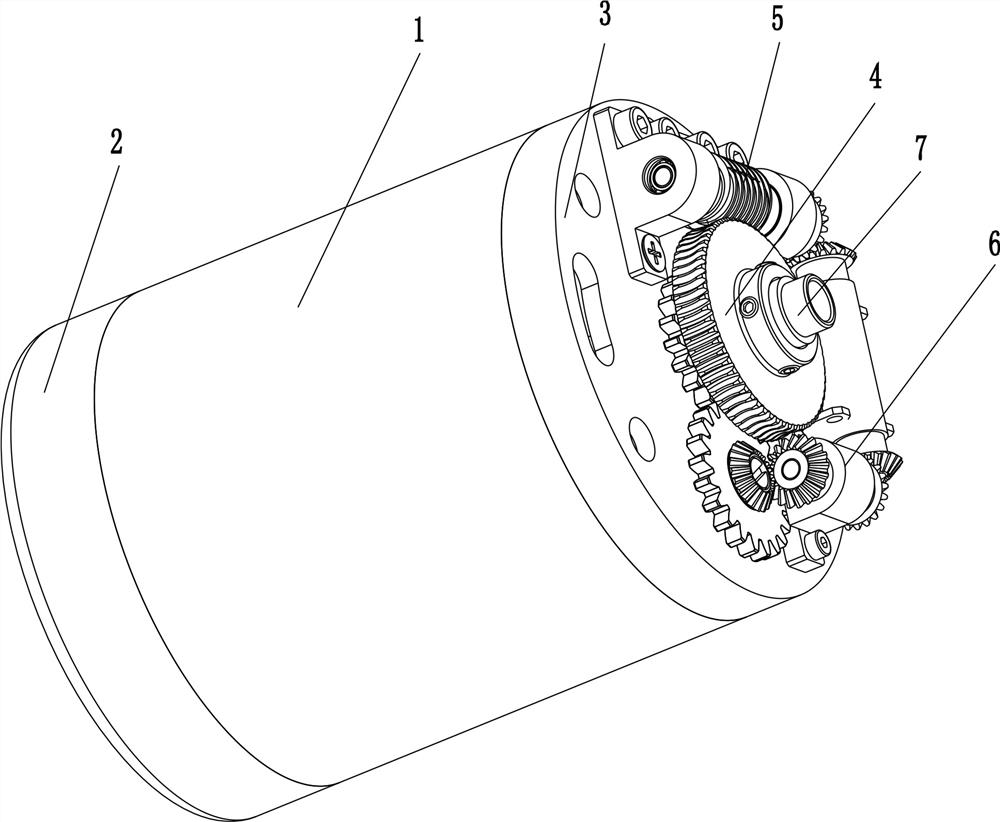

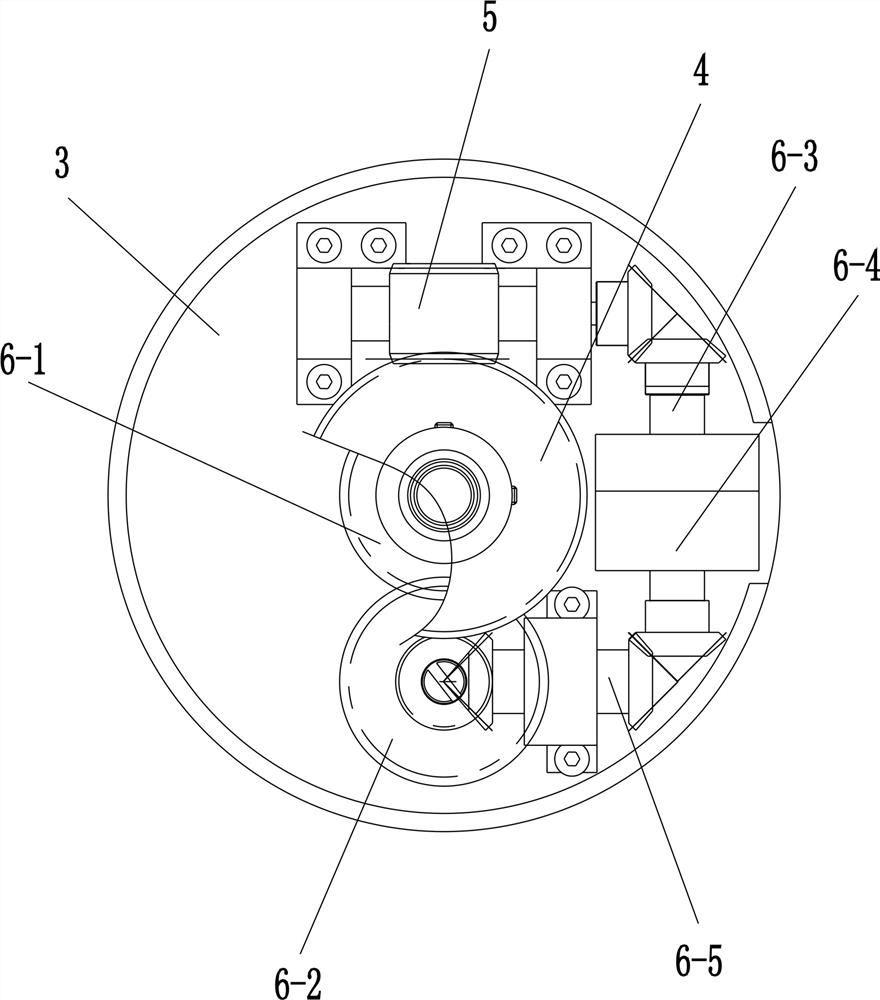

[0029] Embodiment one: see attached Figure 1~3 ;

[0030]The power transmission device 6 includes a gear 6-1, an intermediate wheel I 6-2, a bridge shaft I 6-3 and an electromagnetic clutch 6-4. The motor shaft 8 is provided with a gear 6-1, and the gear 6- 1 is connected to one end of the bridge shaft I6-3 through the corresponding transmission of the intermediate wheel I6-2. The 3-axis body is equipped with an electromagnetic clutch 6-4, and the other end of the bridge shaft I 6-3 is connected to the worm 5 in a corresponding transmission, that is, during normal operation, the electromagnetic clutch 6-4 is closed, so that the motor shaft 8 can drive the gear 6- 1 Drive the intermediate wheel I6-2, the intermediate wheel I6-2 drives the bridge shaft I6-3, and the bridge shaft I6-3 drives the worm 5, so that the worm 5 and the worm wheel 4 run synchronously, thus forming a closed-loop transmission structure; When braking is required, the motor body 1 is disconnected from th...

Embodiment 2

[0031] Embodiment two: see attached figure 1 , 2 and 4;

[0032] The power transmission device 6 includes a pin wheel 6-6, an intermediate wheel II 6-7 and a bridge shaft II 6-8, and the motor shaft 8 is provided with a pin wheel 6-6, and the pin wheel 6-6 is connected to the bridge shaft II 6-8. One end of the bridge shaft Ⅱ6-8 is connected through the corresponding transmission of the intermediate wheel Ⅱ6-7, and the tooth groove width of the pin wheel 6-6 is greater than the tooth thickness of the intermediate wheel Ⅱ6-7, and the intermediate wheel Ⅱ6-7 and the bridge shaft Ⅱ6-8 are both Corresponding to the mounting seat 3, the other end of the bridge shaft II 6-8 is connected to the worm 5 in a corresponding transmission connection, that is, in normal operation, the motor shaft 8 can drive the pin wheel 6-6 to drive the intermediate wheel II 6-7. Wheel Ⅱ6-7 drives the bridge shaft Ⅱ6-8, and the bridge shaft Ⅱ6-8 drives the worm 5, so that the worm 5 and the worm gear 4 ...

Embodiment 3

[0033] Embodiment three: see attached figure 1 , 2 and 5;

[0034] The power transmission device 6 includes an intermediate wheel III 6-10, a bridge shaft III 6-11 and an elastic gear 6-12 whose gear teeth are made of elastomer plastic, and the motor shaft 8 is provided with an elastic gear 6-12, One end of the elastic gear 6-12 and the bridge shaft III 6-11 is connected through the corresponding transmission of the intermediate wheel III 6-10, and the intermediate wheel III 6-10 and the bridge shaft III 6-11 are connected to the mounting seat 3 in rotation correspondingly, so The other end of bridge shaft III 6-11 is correspondingly connected with worm 5, that is, in normal operation, motor shaft 8 can drive elastic gear 6-12 to drive intermediate wheel III 6-10, and intermediate gear III 6-10 drives bridge shaft III 6 -11, the bridge shaft III6-11 drives the worm 5, so that the worm 5 and the worm gear 4 run synchronously, thus forming a closed-loop transmission structure;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com