Construction method capable of manufacturing concrete surface wood grain texture in antique building

A technology of concrete surface and antique architecture, which is applied to the preparation of building components on site, construction, manufacturing tools, etc., can solve the problem that the natural effect of wood grain texture on the concrete surface and the amount of wood used can not be taken into account, so as to achieve reuse and increase Stability, the effect of reducing the intrusion of external erosive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0033] Embodiments of the present invention propose a construction method for making wood grain textures on concrete surfaces in antique buildings, which includes the following steps:

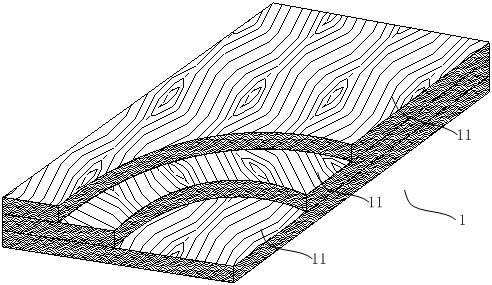

[0034] Step S1: processing the logs into boards.

[0035] When cutting the log, the thickness of the board is preferably 10 mm. In this embodiment, the board is specifically cut to form a 10 mm thick board, so that it can be spliced into a thin board 11 with a thickness of 10 mm. Attention should be paid to the direction of the wood grain and the cross-sectional grain. In order to improve the aesthetics and ensure sufficient hardness, the log is cut according to the direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com