Biosynthetic compound with high light resistance

A biosynthesis and compound technology, applied in the fields of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of unstable chromophore group, poor light fastness, affecting the dyeing effect of dyes, etc. The effect of easy availability of raw materials and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of engineering bacteria for dye preparation:

[0022] With reference to CN102952813B (synthesis method and extraction process of blue natural dye), engineering bacteria for biosynthesis and transformation are prepared.

Embodiment 2

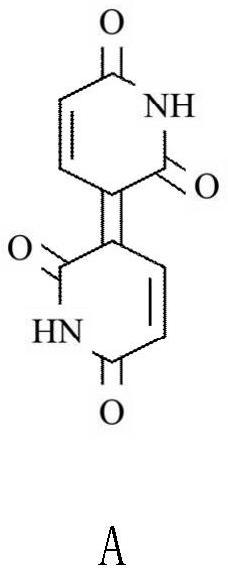

[0024] Preparation of Compound A:

[0025]

[0026] Will 5g Add it into the engineering bacteria culture solution in Example 1, after 24 hours of cultivation, collect the culture solution, obtain the precipitated substance after centrifugation, use DMSO to dissolve the precipitate, and remove the insoluble matter, and evaporate the DMSO to dryness to obtain ash Brown solid powder, yield 92%.

Embodiment 3

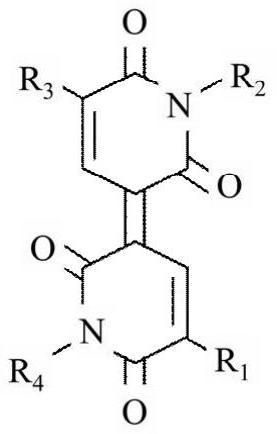

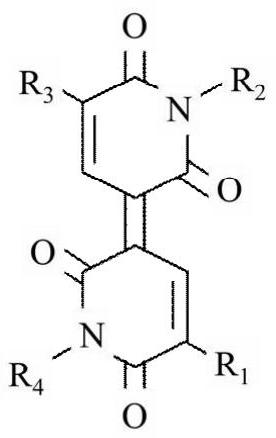

[0028] Preparation of Compound B:

[0029]

[0030]

[0031] Will 5g Add it to the engineering bacteria culture solution in Example 1, after 28 hours of cultivation, collect the culture solution, obtain the precipitated substance after centrifugation, dissolve the precipitate with DMSO, and remove the insoluble matter, and evaporate and dry the DMSO to obtain dark blue Color solid powder, yield 95%.

[0032] Example 3

[0033] Preparation of Compounds C, D, E:

[0034]

[0035] 3g and 3g After 1:1 mixing, it was added to the engineering bacterium culture solution in Example 1. After 32 hours of cultivation, the culture solution was collected, and the precipitate was obtained after centrifugation. The precipitate was dissolved with DMSO, and the insoluble matter was removed. Phase treatment, collect the effluent at 12-15 minutes, 20-25 minutes, and 30-33 minutes respectively, and vacuum dry to obtain dark brown solid powder (C), yellow-brown solid powder (D), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com