Thermosetting resin composition, and bonding sheet, metal foil-clad laminated board and printed circuit board manufactured by using thermosetting resin composition

A resin composition, thermosetting technology, applied in printed circuits, metal layered products, printed circuit components, etc., can solve problems such as inability to meet use requirements, achieve low dielectric loss, broad application prospects, and good compatibility. Effect

Active Publication Date: 2020-09-04

NANYA NEW MATERIAL TECH CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] One of the purposes of the present invention is to provide a thermosetting resin composition to improve the existing thermosetting resin prepared by using polyph

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

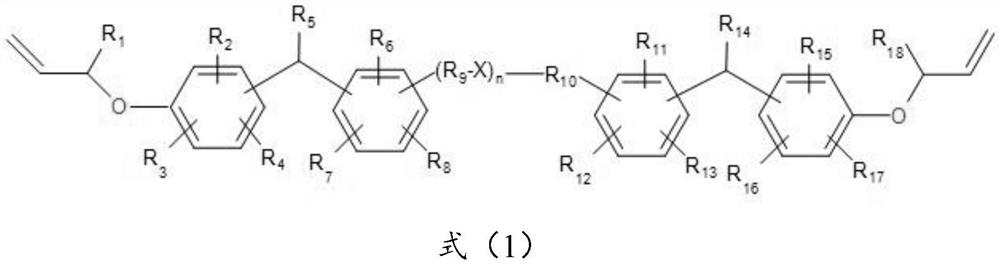

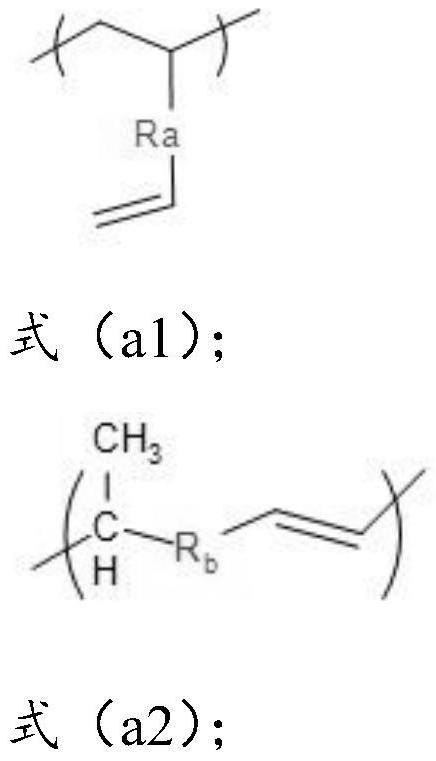

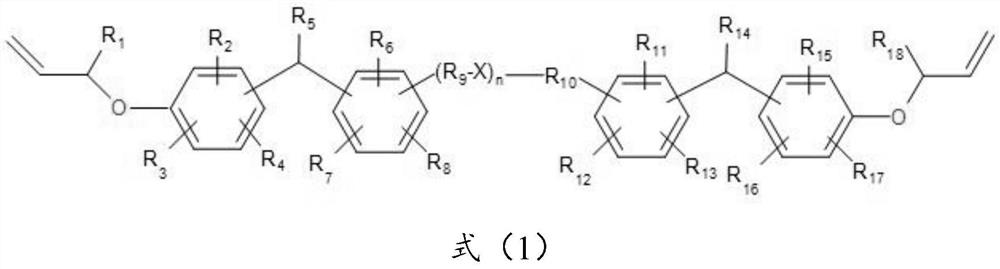

The invention provides a thermosetting resin composition, and a bonding sheet, a metal foil-clad laminated board and a printed circuit board manufactured by using the thermosetting resin composition,and relates to the technical field of thermosetting resin. The thermosetting resin composition comprises the following components in parts by mass: 20-90 parts of allyl ether resin with a polyalicyclic structure and 10-80 parts of a multifunctional vinyl aromatic copolymer. According to the thermosetting resin composition, the allyl ether resin with a polyalicyclic structure is matched with the multifunctional vinyl aromatic copolymer to form a main resin system; according to the present invention, the two components are subjected to copolymerization to form the good network interpenetrating structure, such that the material cured by the resin composition has characteristics of low dielectric constant, low dielectric loss and ultra-low high frequency signal transmission loss, can meet thedielectric property requirement of the region with the frequency of more than or equal to 10 GHz, and has broad application prospects in the field of high frequency transmission.

Description

technical field [0001] The invention relates to the technical field of thermosetting resins, in particular to a thermosetting resin composition and an adhesive sheet, a metal foil-clad laminate and a printed circuit board made of the thermosetting resin composition. Background technique [0002] Mobile communication equipment represented by 5G communication, base stations, servers, routers and other network infrastructure equipment, as well as the high-speed and large-capacity signals used for data storage and computing, are rapidly advancing year by year. Accompanied by this, the printed circuit boards mounted on these electronic devices need to cope with high frequency and high speed, that is, they have low transmission loss in the high frequency band, and usually the substrate material has excellent dielectric properties (low dielectric constant and low dielectric loss tangent). In addition to the above-mentioned communication equipment, in the ITS field (related to auto...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F257/00C08F283/08C08F279/02C08F287/00C08F216/00C08J5/24B32B15/20B32B15/14B32B17/04B32B17/06B32B27/04B32B27/28B32B27/30B32B33/00H05K1/03

CPCC08F257/00C08F283/085C08F279/02C08F287/00C08J5/24B32B5/02B32B15/20B32B15/14B32B33/00H05K1/0366B32B2260/021B32B2260/046B32B2307/204B32B2457/08C08J2351/00C08F216/00

Inventor 李兵兵包欣洋席奎东粟俊华汪泉刘同欢熊记

Owner NANYA NEW MATERIAL TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com