A kind of preparation method of nickel-free duplex stainless steel

A duplex stainless steel, stainless steel technology, applied in solid diffusion coating, coating, metal material coating process and other directions, can solve the problems of nickel allergy, complex process, affecting the cost of stainless steel, etc., to achieve strong anti-rust ability and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

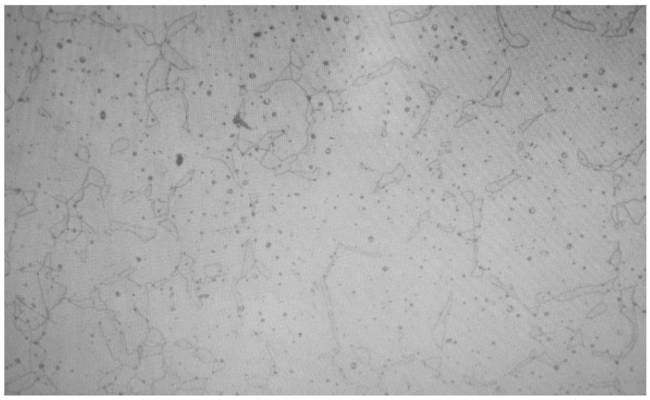

Image

Examples

Embodiment 1

[0017]Preparation method of nickel-free double-phase stainless steel, including the following preparation steps,

[0018](1) Select stainless steel feeding, the stainless steel feed comprises the following raw materials: the metal powder mass fraction is 89-91%, the adhesive mass fraction is 9-11%, the metal powder element component mass fraction is C 0.01 %, N0.53%, CR 16.69%, MO 3.16%, Si 0.46%, MN 10.96%, FE moderate;

[0019](2) Through the injection machine, the stainless steel feeding is formed into a product, the injection conditions are 150-240 MPa, the pressure pressure is 100-150 MPa, and the mold temperature is 110-150 ° C;

[0020](3) Put the molded product into the catalytic degreased furnace, remove the adhesive, the degrease conditions are the furnace cavity temperature of 100-140 ° C, the nitrogen temperature is 100-150 ° C, and the degreasing time is 180-360 min;

[0021](4) Put the degreated product to the sintering furnace for sintering, the temperature is set to room tempera...

Embodiment 2

[0024]Preparation method of nickel-free double-phase stainless steel, including the following preparation steps,

[0025](1) Select stainless steel feeding, the stainless steel feed comprises the following raw materials: the metal powder mass fraction is 89-91%, the adhesive mass fraction is 9-11%, the metal powder element component mass fraction is C 0.01 %, N0.53%, CR 16.69%, MO 3.16%, Si 0.46%, MN 10.96%, FE moderate;

[0026](2) Through the injection machine, the stainless steel feeding is formed into a product, the injection conditions are 150-240 MPa, the pressure pressure is 100-150 MPa, and the mold temperature is 110-150 ° C;

[0027](3) Put the molded product into the catalytic degreased furnace, remove the adhesive, the degrease conditions are the furnace cavity temperature of 100-140 ° C, the nitrogen temperature is 100-150 ° C, and the degreasing time is 180-360 min;

[0028](4) Put the degreated product to the sintering furnace for sintering, the temperature is set to room tempera...

Embodiment 3

[0031]Preparation method of nickel-free double-phase stainless steel, including the following preparation steps,

[0032](1) Select stainless steel feeding, the stainless steel feed comprises the following raw materials: the metal powder mass fraction is 89-91%, the adhesive mass fraction is 9-11%, the metal powder element component mass fraction is C 0.01 %, N0.53%, CR 16.69%, MO 3.16%, Si 0.46%, MN 10.96%, FE moderate;

[0033](2) Through the injection machine, the stainless steel feeding is formed into a product, the injection conditions are 150-240 MPa, the pressure pressure is 100-150 MPa, and the mold temperature is 110-150 ° C;

[0034](3) Put the molded product into the catalytic degreased furnace, remove the adhesive, the degrease conditions are the furnace cavity temperature of 100-140 ° C, the nitrogen temperature is 100-150 ° C, and the degreasing time is 180-360 min;

[0035](4) Put the degreated product to the sintering furnace for sintering, the temperature is set to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com