700 MPa grade low temperature quenched and tempered steel plate with excellent weldability and fatigue resistance and manufacturing method thereof

A technology of low-temperature quenching and tempering and manufacturing methods, which is applied in the field of 700MPa low-temperature quenched and tempered steel plates and their manufacturing, and can solve problems such as weak anti-fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

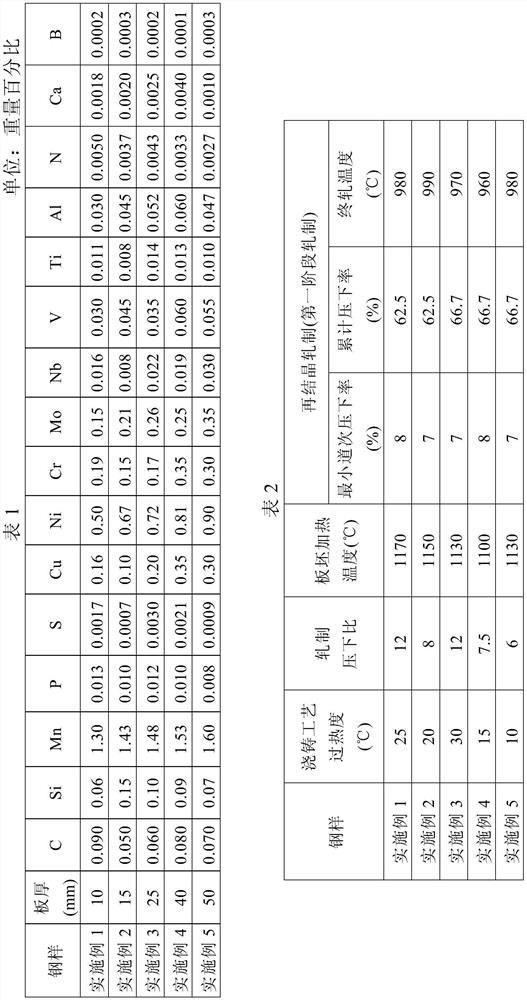

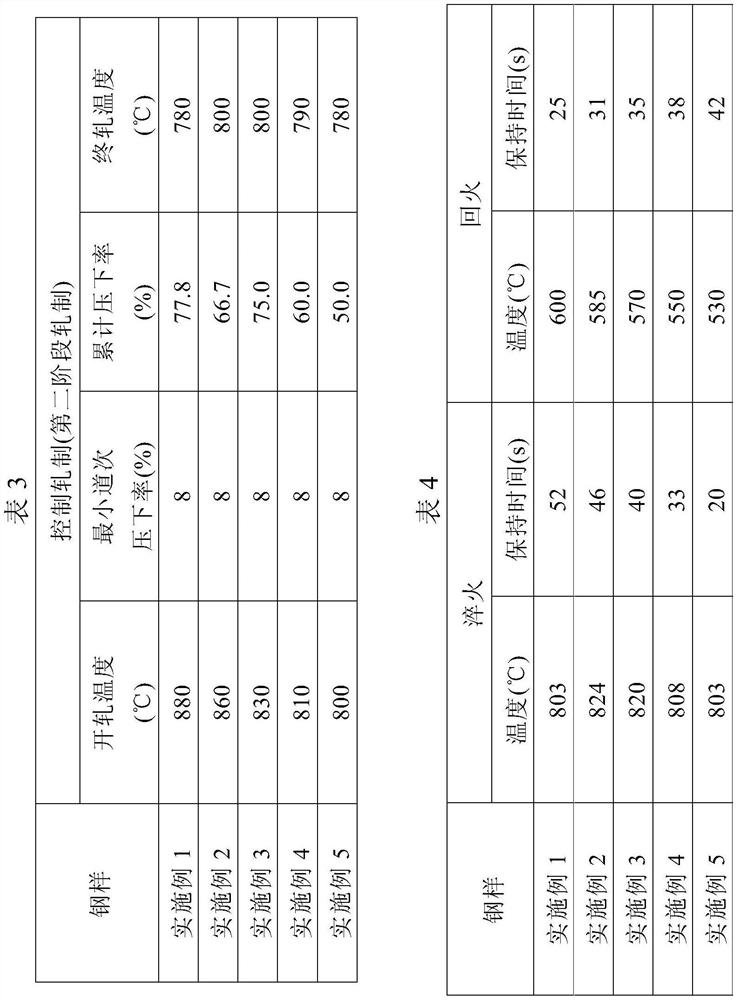

[0075] For the composition of the steel plate in the embodiment of the present invention, refer to Table 1, and Table 2 to Table 5 show the manufacturing process of the steel plate in the embodiment of the present invention. Table 5 shows the performance parameters of the steel plates of the embodiments of the present invention.

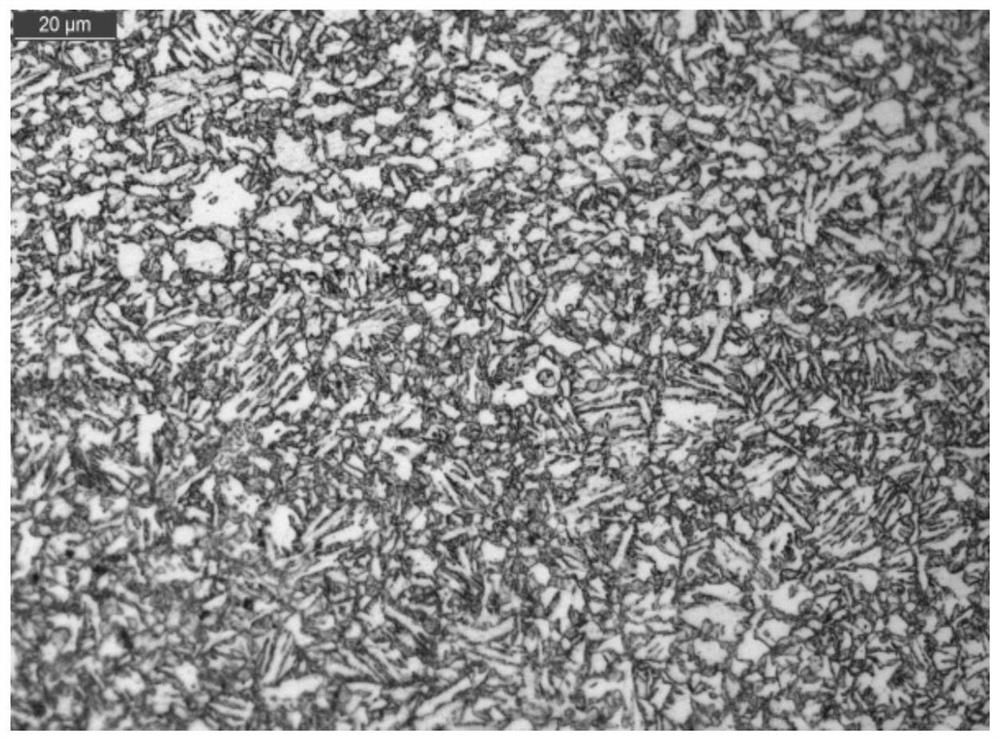

[0076] Depend on figure 1 From the microstructure of the steel plate in Example 3 of the present invention, it can be seen that the microstructure of the steel plate is fine and uniform pro-eutectoid massive ferrite+low carbon lower bainite (the ultra-low carbon bainite in this figure is the fire state), the comprehensive mechanical properties and weldability of the steel plate in Example 3 are extremely good, and have reached the technical requirements of the invented steel plate.

[0077] In summary, the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com