A Fault Detection Method for Wind Tunnel Balance Bridge

A technology for wind tunnel balance and fault detection, which is applied to electromagnetic measuring devices, electric/magnetic solid deformation measuring, measuring devices, etc. It can solve problems such as low efficiency and difficult faults of balance bridges, so as to reduce labor intensity and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

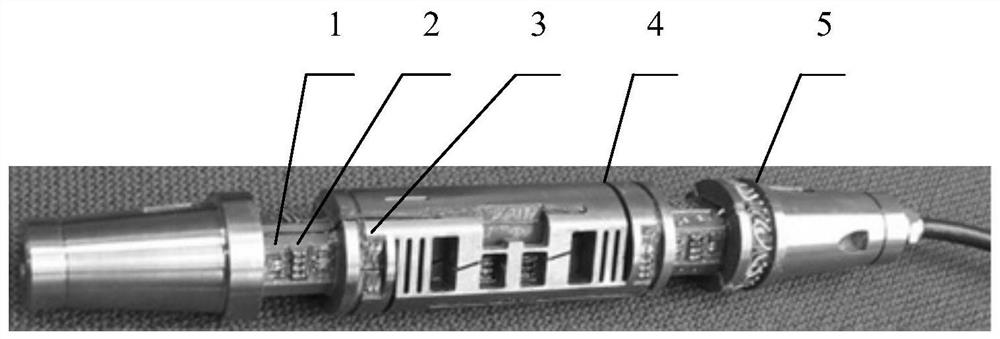

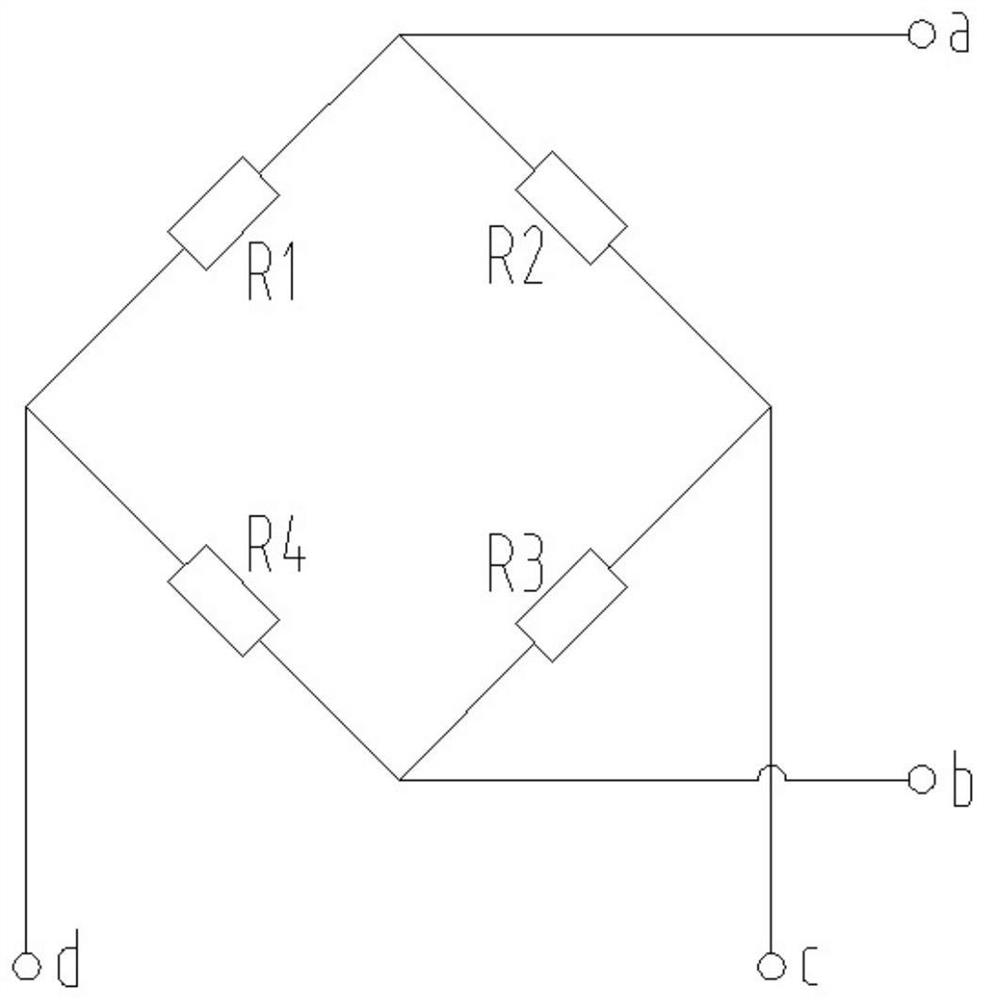

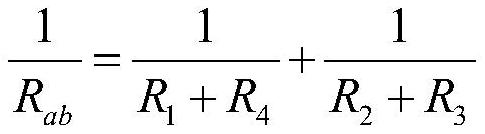

[0026] The invention provides a wind tunnel balance bridge fault detection method. Such as figure 1 As shown, it is a typical conventional wind tunnel balance with six components, that is, six bridges, including strain gauge 1, terminal 2, balance inner lead 3, balance body 4, balance outer lead 5 resistance values, etc. Such as figure 2 As shown, each bridge consists of four bridge arms, and each bridge arm is composed of several strain gauges, usually one or two, depending on the specific structure of the balance. When the balance bridge fails, the balance maintenance personnel need to check each position of the entire bridge one by one to determine the fault location. Due to the limitation of the working environment on the wind tunnel, the investigation is difficult, takes a long time, and takes up a lot of precious time. Wind tunnel test time.

[0027] This method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com