Method for testing anti-re-alkali performance of spray material for coal mine roadway

A technology of coal mine roadway and testing method, which is applied to a measuring device, removes certain components for weighing, and measures directions such as ultrasonic/sonic/infrasonic waves, which can solve the problem of inability to accurately judge the anti-alkalinity performance of sprayed materials, and achieve accurate Improve and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

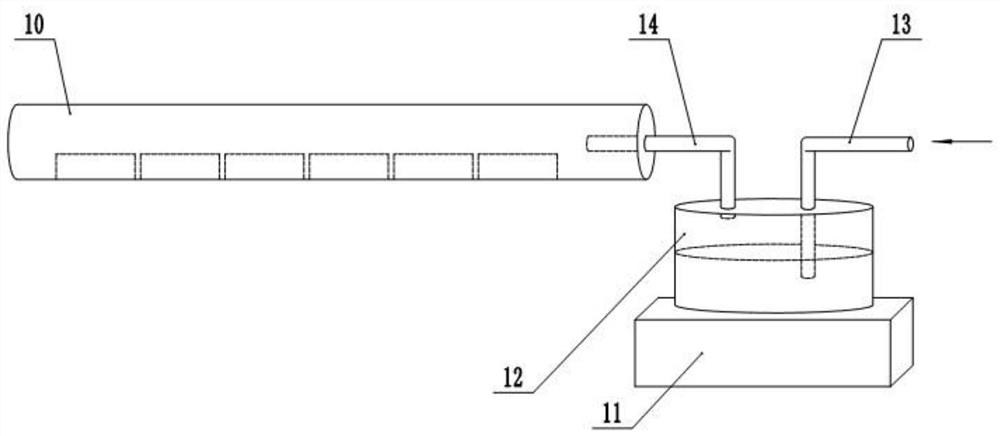

[0026] The reference numerals in the drawings of the specification include: a tube furnace 10 , a heating platform 11 , a water tank 12 , an air inlet pipe 13 , and an exhaust pipe 14 .

[0027] A method for testing the anti-alkali performance of spray materials for coal mine roadways. The test object is a spray material for coal mine roadways. The spray materials include 50-100 parts by weight of borax, 150-500 parts of Spraying material, 100-300 parts of fly ash and 100-200 parts of crushed stone and cinder, the special anti-foaming thickener YR-910 is also added to the spraying material, and the mass of the thickener accounts for 0.5-20% of the total mass of the spraying material. 2%.

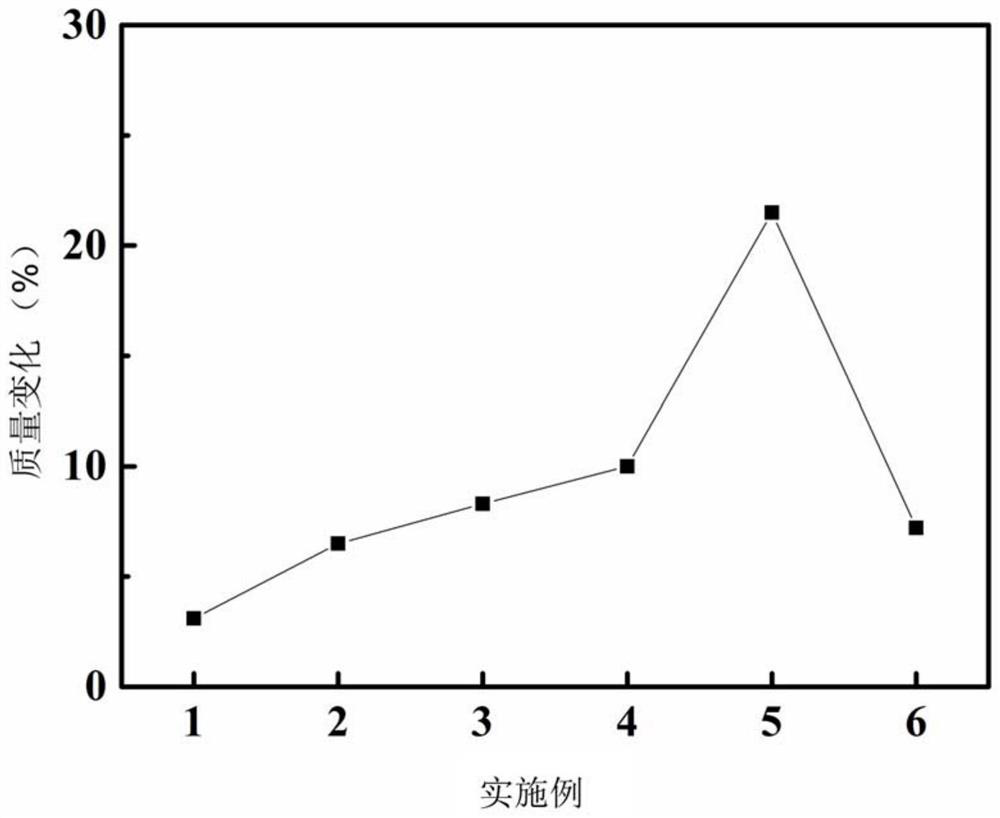

[0028] The components and test parameters of Examples 1-6 of the test method are shown in Table 1 and Table 2.

[0029] Table 1 shows the parameters of spraying materials used in coal mine roadwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com