Double-deep-position four-way shuttle vehicle system order sorting optimization method considering goods pouring strategy

A technology for sorting optimization and shuttle car, which is applied in the field of order sorting optimization of double-deep four-way shuttle car system, which can solve the problems of reduced operation efficiency, infeasible scheduling and optimization of four-way shuttle car system, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0146] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

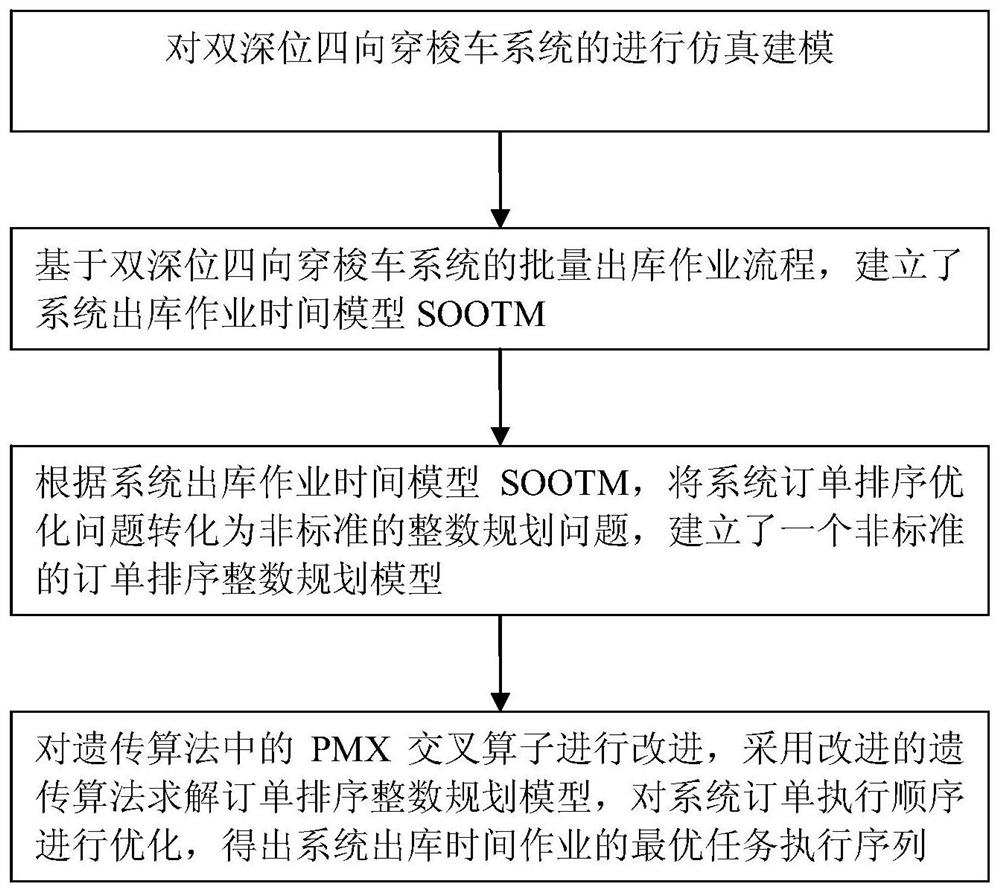

[0147] Such as figure 1 As shown, an order sequencing optimization method for a double-deep four-way shuttle system considering the restocking strategy includes the following steps:

[0148] Step 1: Simulation modeling of the double-deep four-way shuttle system.

[0149] The double-deep four-way shuttle system consists of two dimensions: the hardware part and the software part. The hardware part includes double-deep three-dimensional shelves, four-way shuttle cars, high-speed bin elevators, plastic turnover boxes, conveyor lines and other equipment , the software part includes order management system WMS, warehouse scheduling system WCS and warehouse execution system WES software.

[0150] Since the order sequencing optimization problem of the double-deep four-way shuttle system is too complicated, the present invention proposes the following assumpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com