A shredder suitable for ultra-high speed cigarette making machine

A cigarette machine and pulverizer technology, applied in grain processing and other directions, can solve problems such as large differences in performance indicators such as waste hardness, affecting the normal operation of equipment, passivation of knife edges, etc., to increase equipment stability, reduce maintenance time, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

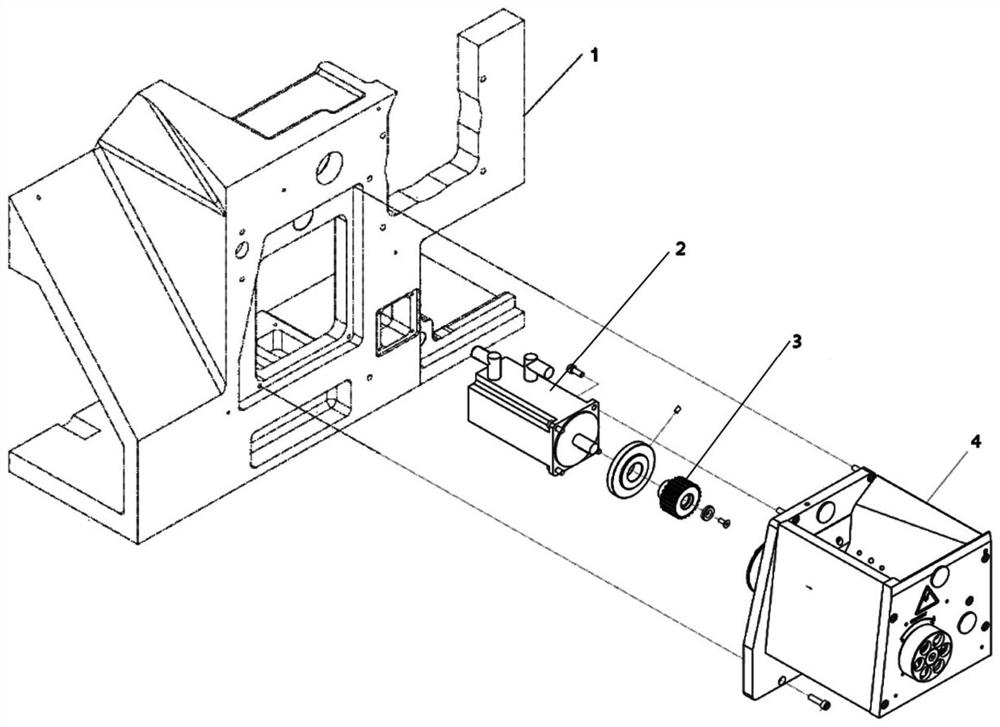

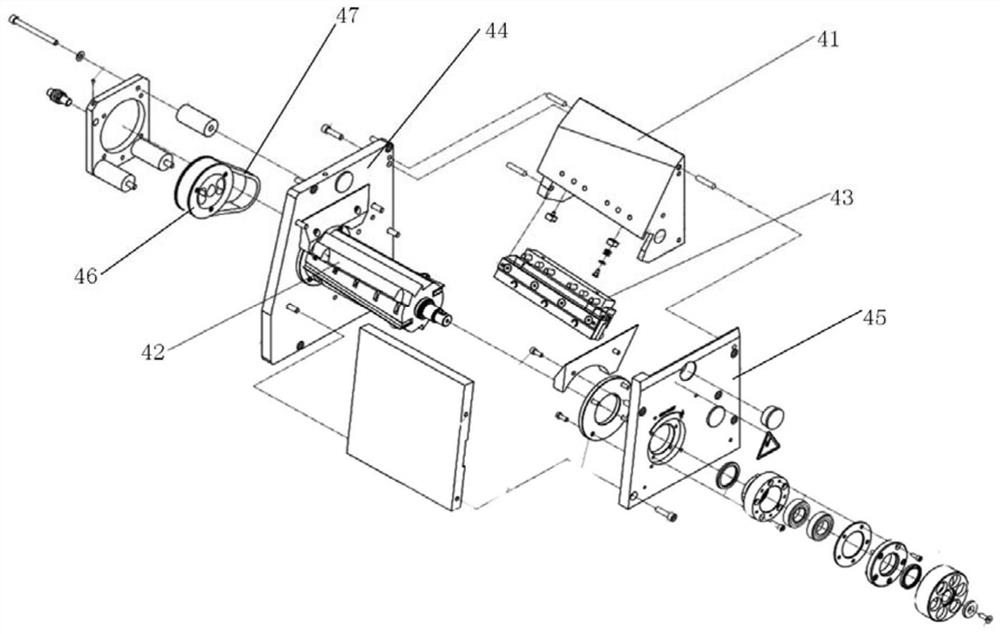

[0027] Such as Figure 1 to Figure 4 The shredder shown is suitable for ultra-high-speed cigarette making machines, including a shredding device 4 and a motor that drives the shredding device 4 to run. Servo motor 2 is used to control the ratio of the speed of the pulverizer to the speed of the tobacco rod by setting the "proportional coefficient of the pulverizer", so as to realize the pulverization of the tobacco rod with a fixed length.

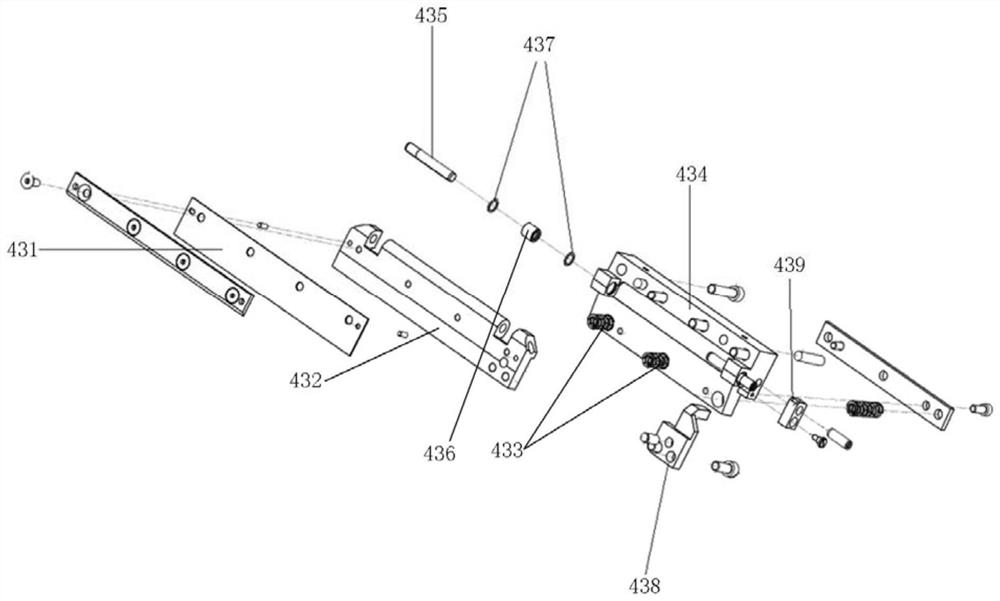

[0028] The crushing device includes a support frame, a hob 42 and a base 43, the hob 42 is rotatably arranged in the support frame, the base 43 is fixed in the support frame, and the base 43 is in clearance fit with the hob 42, The base 43 includes a rotating shaft pin 435, a knife rest 432 and a fixed seat 434, the first blade 431 is fixed on one side of the knife rest 432, and the two ends on one side of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com