Rubber waterstop low-temperature one-time rubber refining production line

A rubber waterstop and production line technology, which is applied in the field of rubber waterstop low-temperature primary rubber mixing production line, can solve the problems of great threat to the stability of rubber material quality, low output of rubber waterstop, irritating smell of film, etc. Achieve the effects of improving ambient temperature and workshop air quality, reducing equipment cost investment, and uniform vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

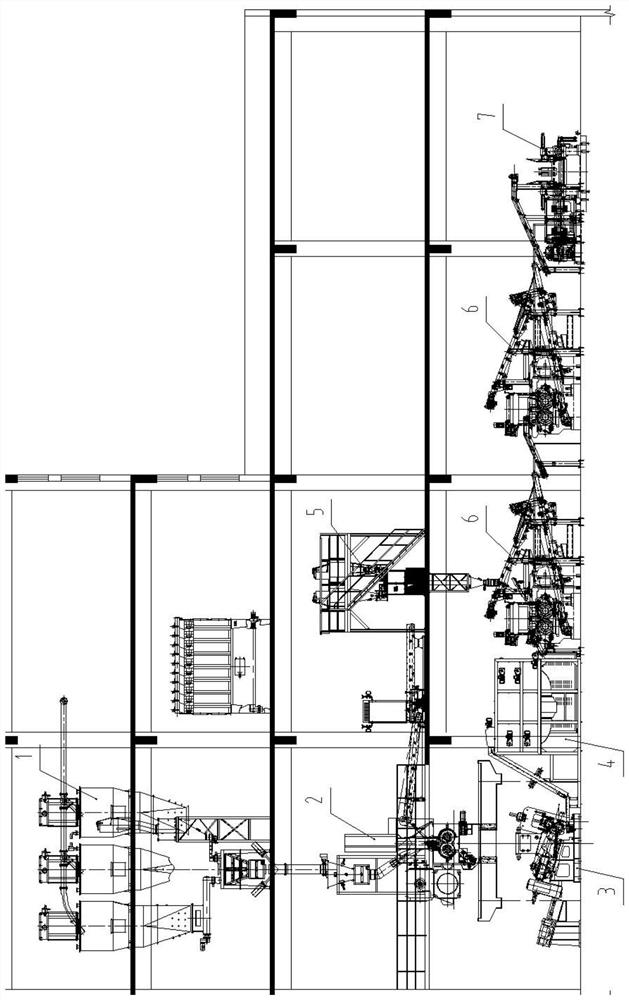

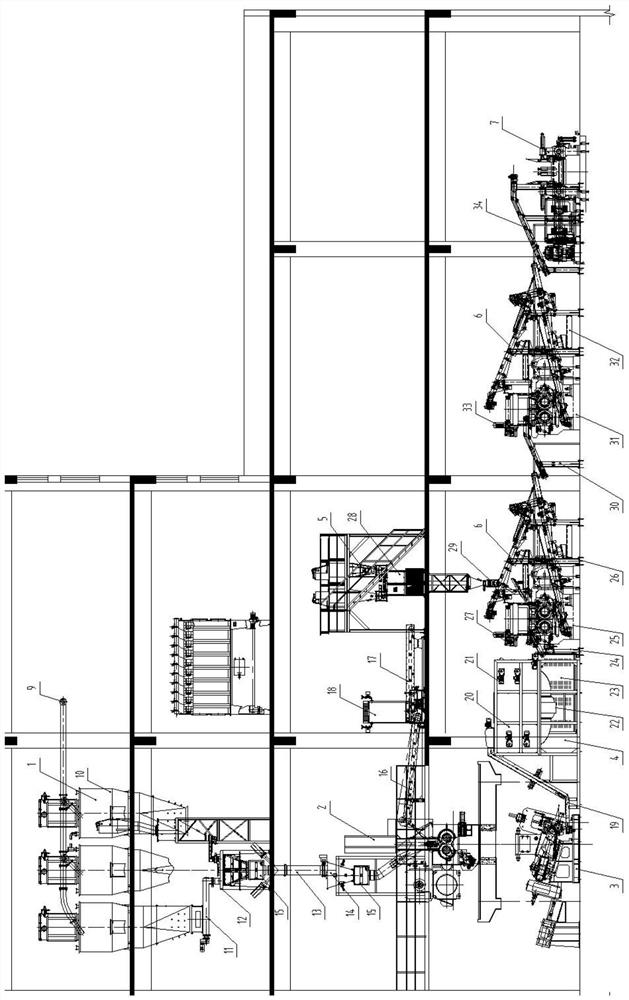

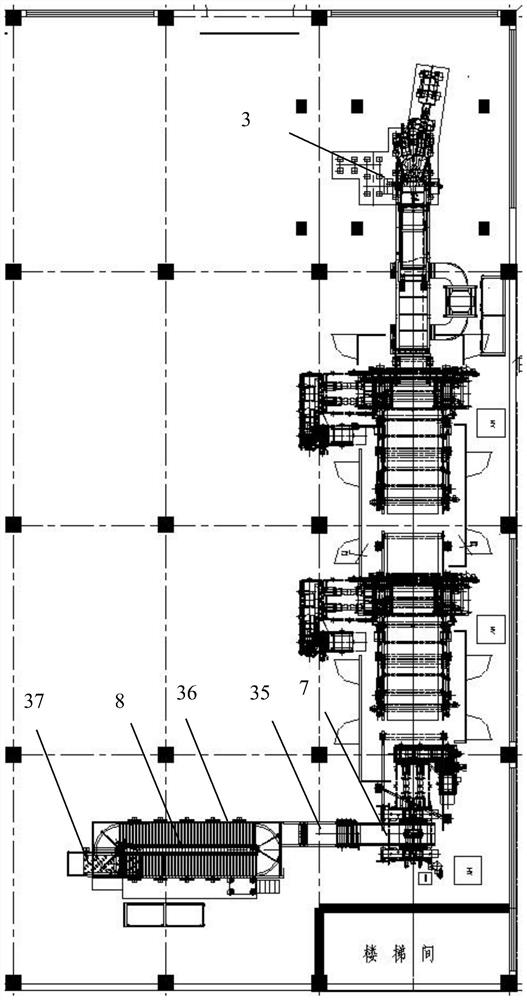

[0031] In order to better understand the purpose, structure and function of the present invention, a low-temperature single-stage rubber mixing production line for rubber waterstops of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] Such as Figure 1 to Figure 3 As shown, it is shown as a rubber waterstop low-temperature one-step rubber mixing production line of the present invention, which is used for a rubber waterstop rubber mixing production line, including an auxiliary machine 1 on an internal mixer, an internal mixer 2, and a twin-screw extrusion press. Tablet machine 3, masterbatch cooling line system 4, vulcanization aid weighing and feeding system 5, fully automatic rubber turning and mixing system 6, tablet press machine 7, annular film cooling line 8 and control system.

[0033] Furthermore, the upper auxiliary machine 1 of the internal mixer has a four-layer three-dimensional structure, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com