On-site high-precision heat treatment device for steam turbine blades

A heat treatment device, steam turbine blade technology, applied in heat treatment furnaces, heat treatment equipment, furnaces and other directions, can solve the problems of poor temperature uniformity, low efficiency, low precision, etc., to achieve clean temperature uniformity, no pollution, good temperature uniformity, heating large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

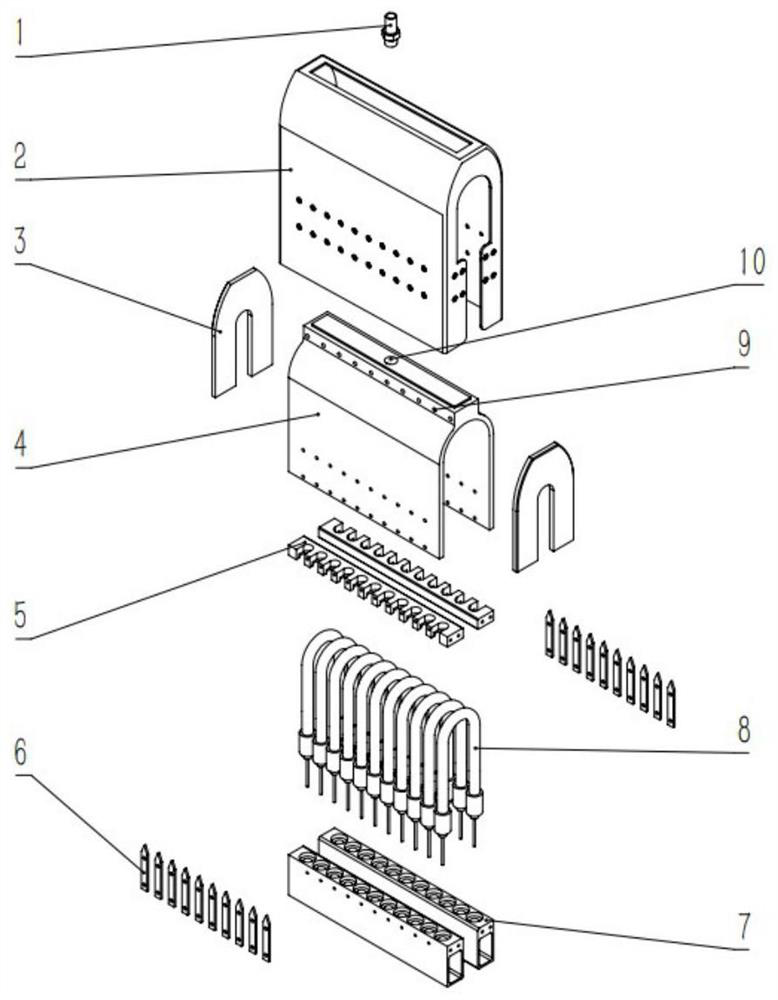

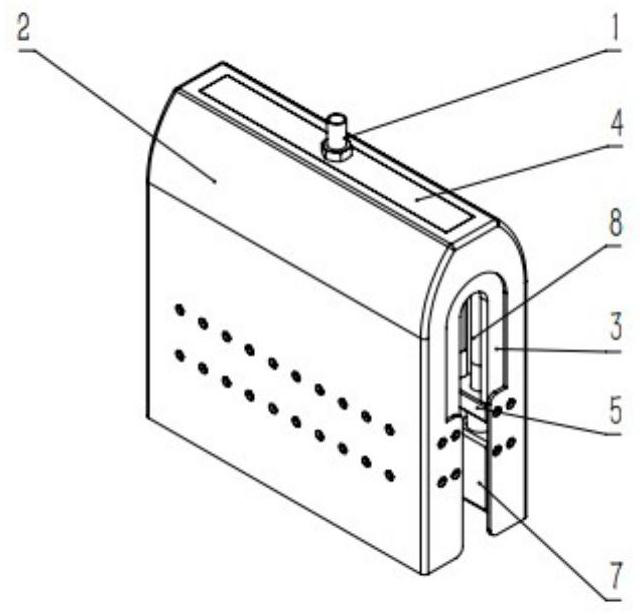

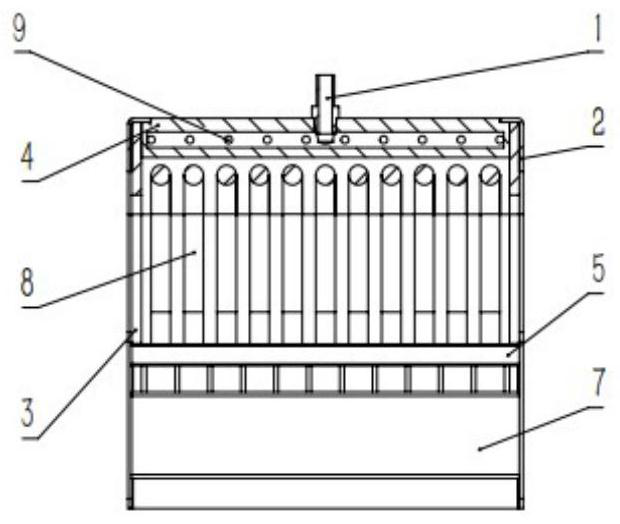

[0026] Such as Figure 1 to Figure 3 As shown, an on-site high-precision heat treatment device for steam turbine blades provided by the present invention is mainly composed of 10 parts: cooling pipe joint 1, infrared heater shell 2, end limit protection plate 3, infrared reflection-installation The base body 4, the upper fixture 5 of the infrared lamp tube, the shell mounting gasket 6, the lower fixture 7 of the infrared lamp tube, the infrared heating tube 8, the cooling port 9, and the joint installation hole 10.

[0027] In this device, the upper fixture 5 of the infrared lamp and the lower fixture 7 of the infrared lamp fix the infrared heating tube 8 in the infrared reflection-installation base 4 to form a heating space. The infrared heater shell 2 is welded to the top of the infrared reflection-mounting base 4, and the shell mounting gasket 6 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com