Device for collecting anode mud pipelines in electrolytic cell for electrolysis technology

A collection device and anode slime technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of high maintenance cost, reduced structural strength of the tank body, easy leakage at the interface, etc., and achieve simple production and installation, beautiful space occupation, and The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] In conjunction with the accompanying drawings, the present invention is described in detail.

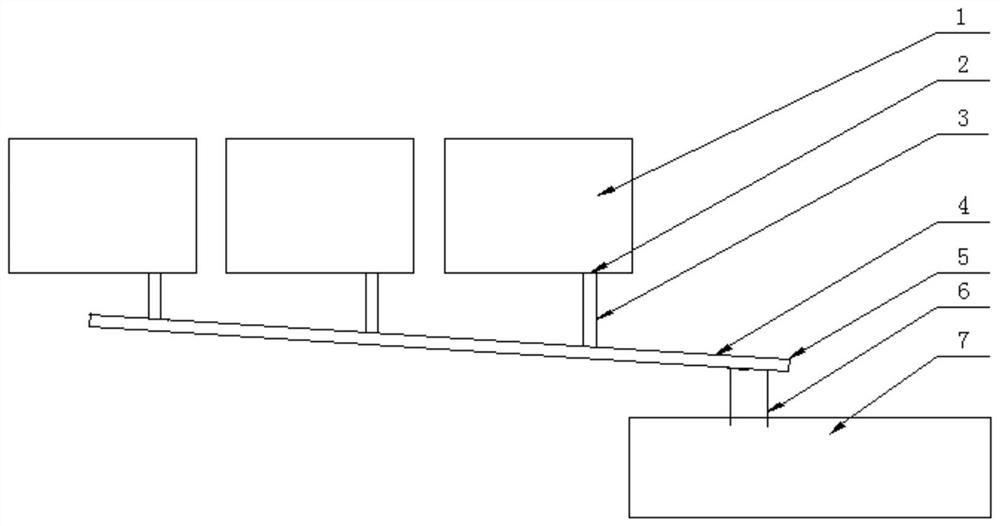

[0024] The present invention provides a kind of anode slime pipe collection device in the electrolytic cell used for electrolysis process during concrete implementation, comprises electrolytic cell 1, and the bottom of described electrolytic cell 1 is provided with anode slime discharge port 2, and described anode slime discharge port 2 is connected with an anode slime discharge pipe 3. Below the anode slime discharge pipe 3, there is an obliquely arranged anode slime collection and delivery chute 4. The high end and low end of the anode slime collection and delivery chute 4 are The end flanges 5 of the slide pipes are arranged at each end, and the bottom of the anode slime collection and delivery slide pipe 4 is provided with a drain pipe 6 and an anode slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com