A method of improving oil recovery after polymer flooding

A polymer and oil recovery technology, applied in drilling compositions, chemical instruments and methods, production fluids, etc., can solve problems such as economic decline, high cost of oil displacement systems, and difficulty in large-scale application. Achieve the effects of increasing swept volume, enhancing oil recovery, and improving oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

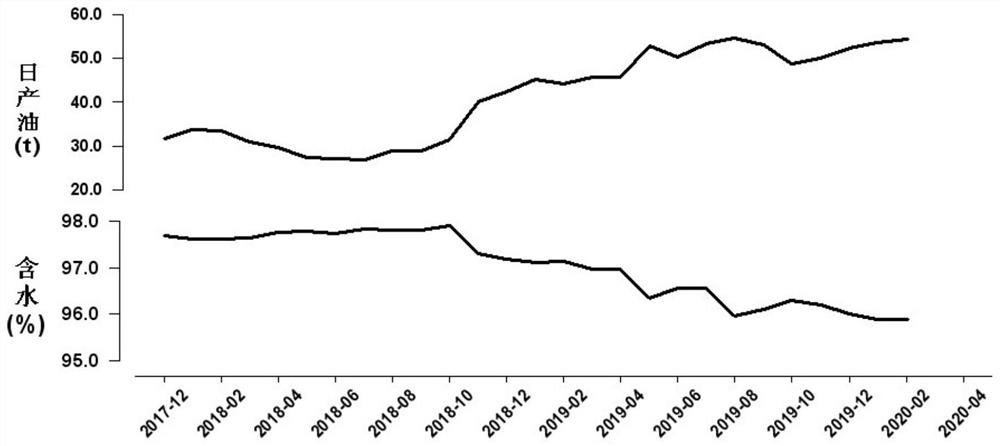

Image

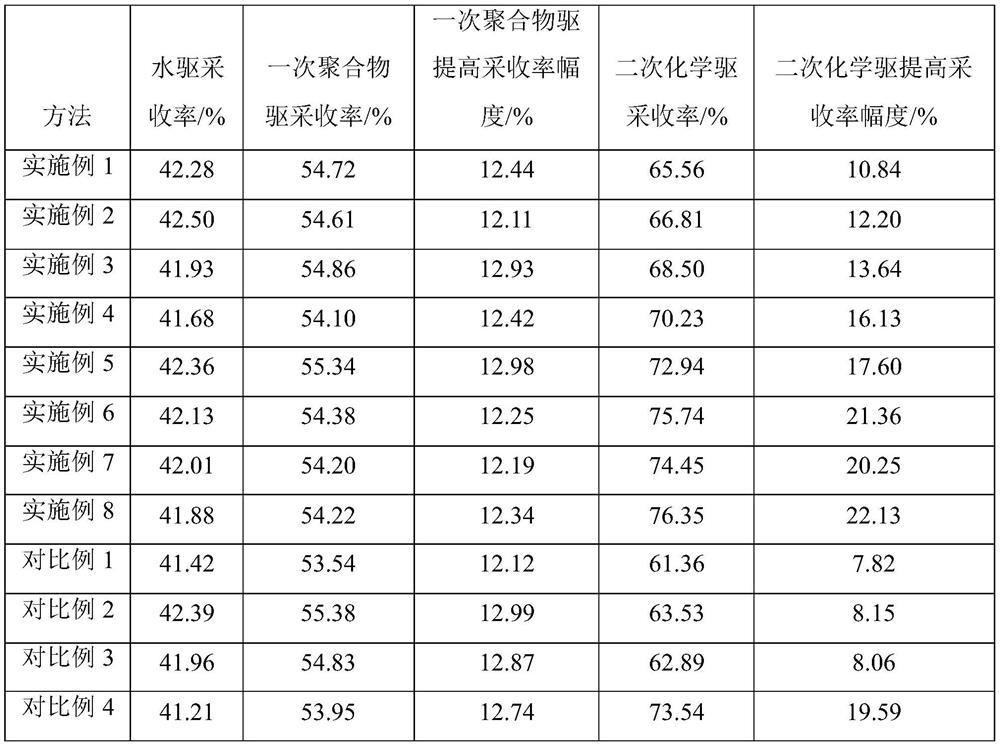

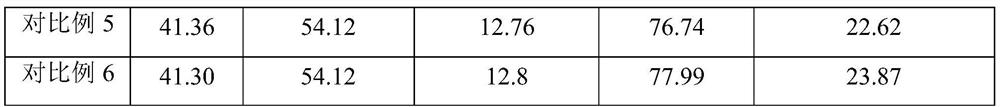

Examples

Embodiment 1

[0028] The polymer used in this example is polyacrylamide with a number average molecular weight of 32 million, its degree of hydrolysis is 28.6%, the effective solid content of viscoelastic particles PPG is 86.5%, and the particle size is 300-900 μm. The mixed aqueous solution of polymer plus PPG is prepared from polymer, PPG and aging sewage, and the polymer aqueous solution is prepared from polymer and aging sewage.

[0029] The method for improving the oil reservoir recovery after polymer flooding of the present embodiment specifically includes:

[0030] (1) Inject the mixed aqueous solution of polymer plus PPG into the core at a flow rate of 50mL / h to form a 0.05PV pre-profile control slug, wherein the mass percentage of polyacrylamide is 0.15%, and the mass percentage of PPG is 0.15%. Then inject a polyacrylamide aqueous solution with a concentration of 1500 mg / L to form a 0.5PV intermediate body slug, wherein the mass percentage of polyacrylamide is 0.15%; finally injec...

Embodiment 2

[0033] For the method of improving the oil recovery after polymer flooding in this embodiment, refer to Embodiment 1, and the difference is only that the injection volume of the middle main slug in step (1) is 0.45PV, and the injection volume of the post profile control slug is 0.45PV. The volume is 0.10PV.

Embodiment 3

[0035] For the method of improving the oil recovery after polymer flooding in this embodiment, refer to Embodiment 2, and the difference is only in that the pre-profile control slug and the PPG mass percentage in the post-profile control slug in step (1) Both are 0.15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com