Oil cylinder load test platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

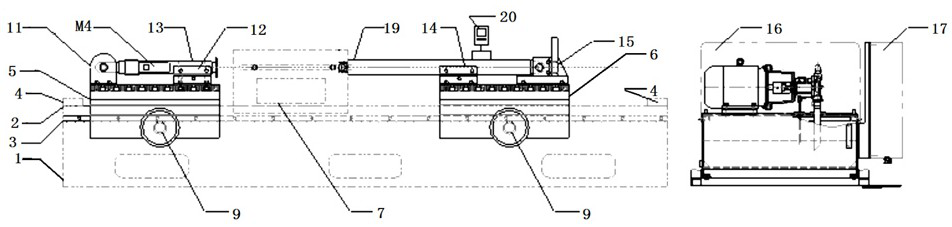

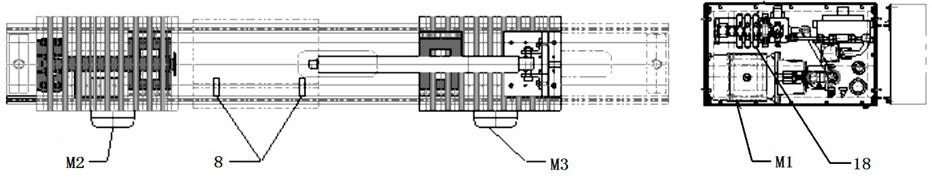

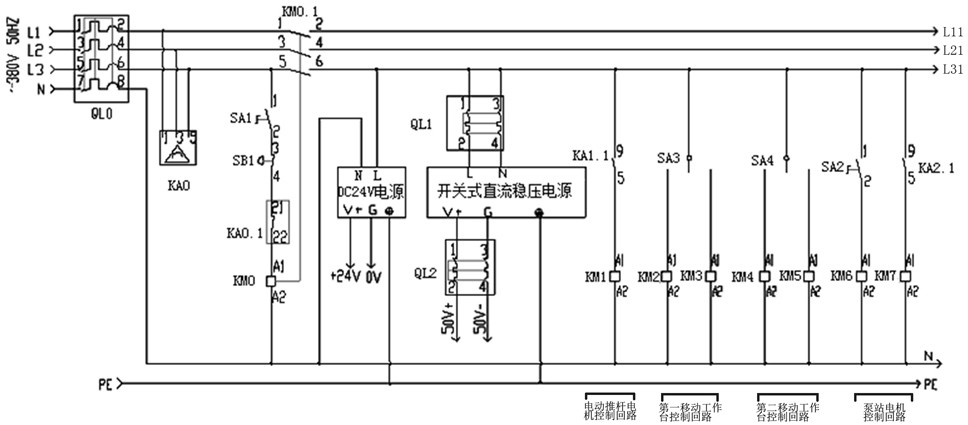

[0045] Such as Figure 1 to Figure 5As shown, the oil cylinder loading test platform of the present invention includes a base 1, the base 1 is connected and fixed with the guide rail 2 by bolts, a rack 3 is also arranged between the base 1 and the guide rail 2, and the two ends of the guide rail 2 are arranged The limit block 4, the guide rail 2 is provided with a first mobile worktable 5 and a second mobile workbench 6, and an oil cylinder position switch bracket is also arranged between the first mobile workbench 5 and the second mobile workbench 6 7. An oil cylinder position switch 8 is installed on the oil cylinder position switch bracket 7;

[0046] The bottoms of the first mobile table 5 and the second mobile table 6 are all provided with a pair of driving gears 9, and the driving gears 9 are engaged with the rack 3, so that the first mobile table 5 and the second mobile table 6 Move horizontally on the base 1, the drive gear 9 is driven by a drive motor control;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com