Lead-acid storage battery grid continuous casting lead liquid supply system

A lead-acid battery and supply system technology, which is applied to casting equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve the unsatisfactory use effect of lead-acid battery grid continuous casting technology, continuous casting grid There are many pores, which affect the strength of the grid, etc., so as to improve the internal pores, improve the molding quality, and facilitate the degassing and slag removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

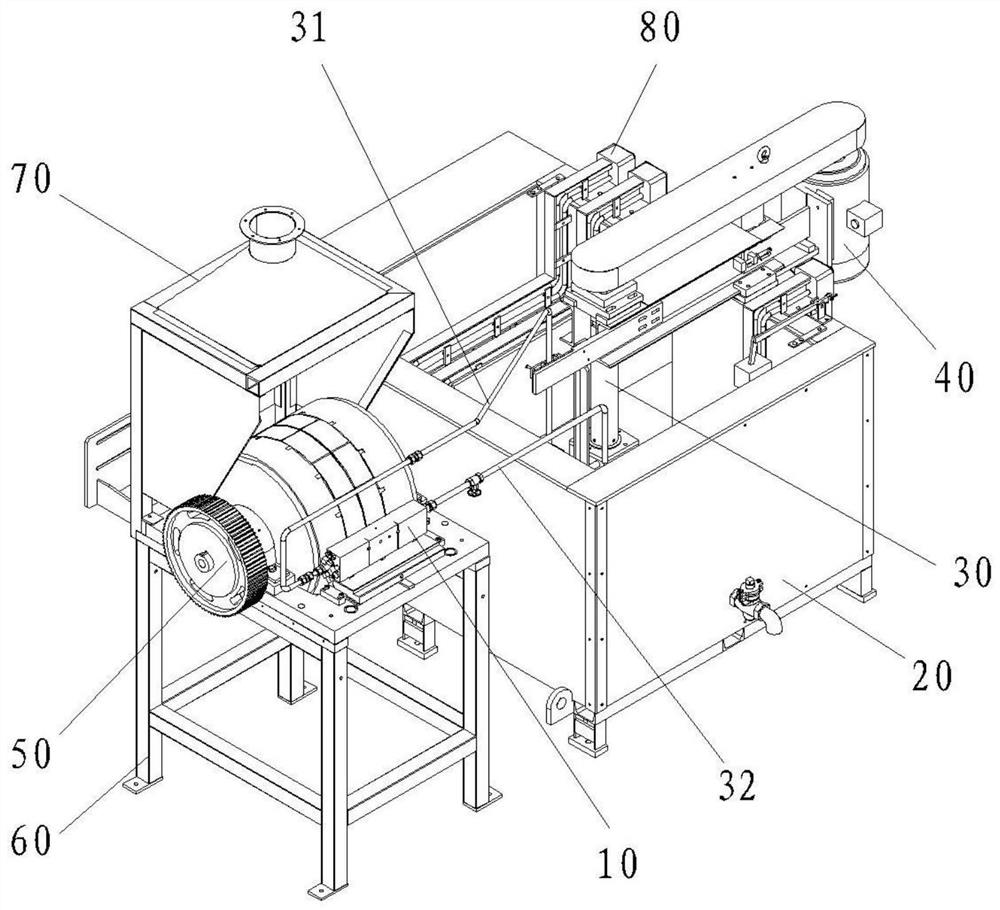

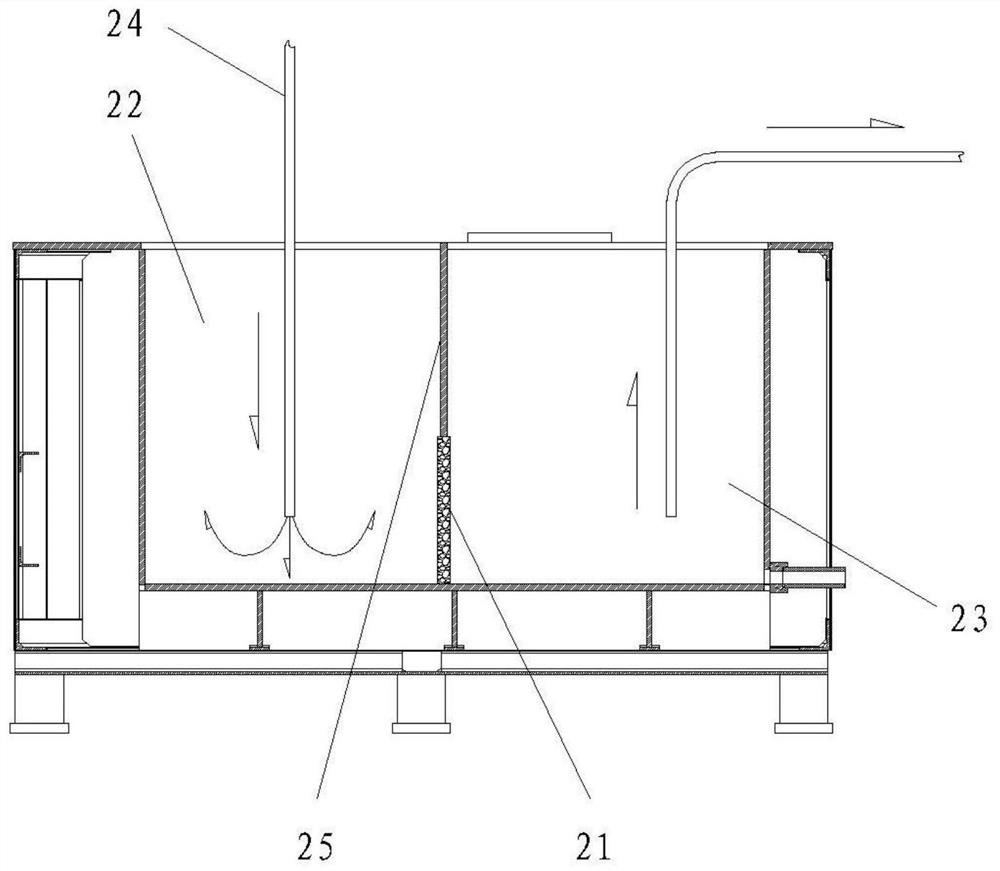

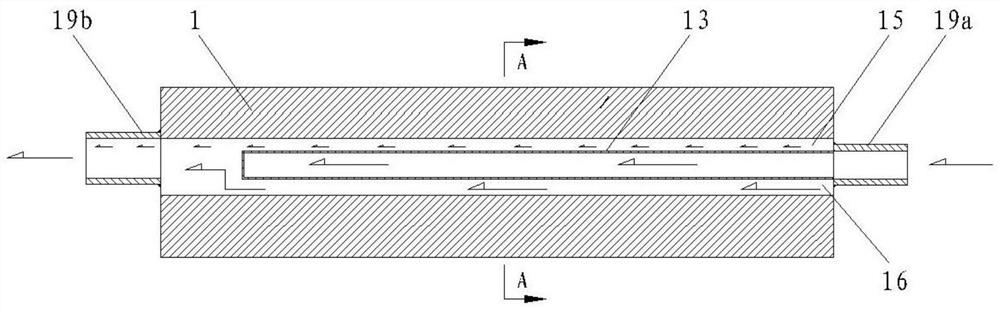

[0022] figure 1 It is a structural schematic diagram of the present invention; figure 2 Schematic diagram of the structure of the lead melting furnace; image 3 It is a schematic diagram of the fixed mold structure; Figure 4 for image 3 Schematic diagram of the cross-sectional structure of A-A;

[0023] As shown in the figure: the lead-acid battery grid continuous casting lead liquid supply system of the present embodiment includes a fixed mold 10 and a lead melting furnace 20 for supplying lead liquid to the fixed mold, and the cavity of the lead melting furnace 20 passes through a filter screen 21 It is divided into a lead melting pool 22 and a working pool 23. After the lead block is placed in the melting lead pool 22 and melted, the lead liquid flows through the filter screen into the working pool 23 and the lead liquid is supplied to the fixed mold. The liquid outlet of the lead melting furnace can be directly connected to the liquid inlet of the fixed mold, or the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap