Oil field fracturing flow-back fluid purification treatment device

A technology for purification treatment and oil field fracturing, applied in the field of fracturing flowback fluid purification treatment, can solve the problems of slow mixing speed of mixing equipment, easy clogging of filter screens, poor mixing uniformity, etc., so as to improve mixing uniformity and ensure purification. quality, the effect of improving the purification rate

Active Publication Date: 2020-09-11

HUBEI PETROKH MACHINE MFG

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Fracturing fluid is an important part of fracturing technology. Its main function is to create fractures and transport proppant along the open fractures. Therefore, the viscosity of the fluid is very important, and it can be flowed back quickly after operation with oily water. Further, the fracturing flowback fluid is formed, and with the continuous extension of oil exploitation time, the produced water continues to rise, and some even reach more than 90%, the sewage treatment volume increases rapidly, which brings huge pressure to environmental protection, so it is necessary to The fracturing flowback fluid can only be discharged outside after undergoing strict purification treatment. The patent application publication number is CN201910711767.8, which discloses a shale gas fracturing flowback fluid treatment method and system device. The existing The fracturing flowback fluid purification treatment device has the advantages of mature technology, firm structure, simple operation, etc., and can meet the requirements for the purification treatment of oil field fracturing flowback fluid. However, for the existing fracturing flowback fluid purification treatment device In other words, on the one hand, after chemical purification treatment, a certain amount of pollutants in the water often remain in the form of ions, which cannot be completely removed. If it is treated again with chemical agents, it is necessary to add a whole set of treatment equipment. Increasing the investment of equipment is not conducive to popularization and use. On the other hand, when using chemicals for purification treatment, it is necessary to completely mix the chemicals with the fracturing flowback fluid. The mixing speed of ordinary mixing equipment is slow, and the mixing effect is poor. It is beneficial to improve the purification treatment speed of the fracturing flowback fluid. On the other hand, after the purification treatment with chemicals, the sediment generated is easy to block the filter screen during the filtration process, which needs to be replaced or cleaned regularly, which affects the operation of the equipment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

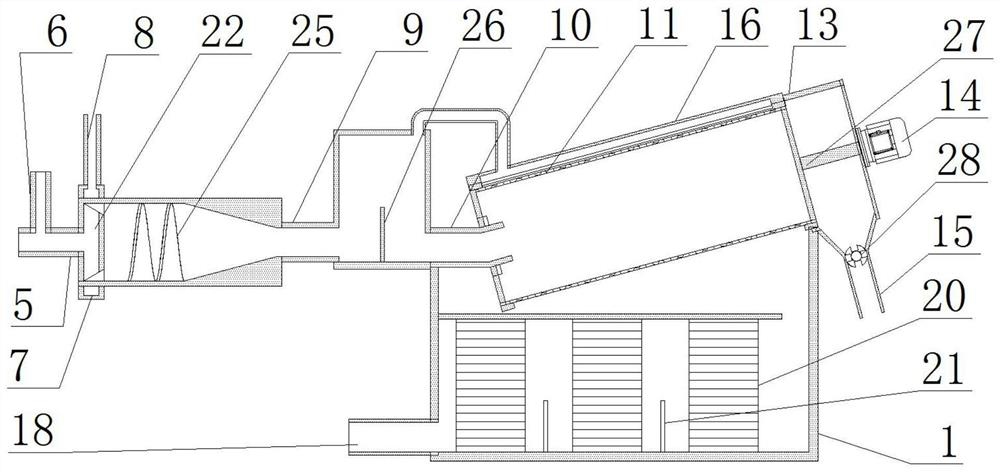

[0025] As a preferred embodiment of the present invention, the switch one 31 is connected with the motor 14 and the feeding valve 28 through wires, and the switch two 32 is connected with the intelligent controller 19, the electrode adsorption plate 20 and the water quality detector 21 through wires .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

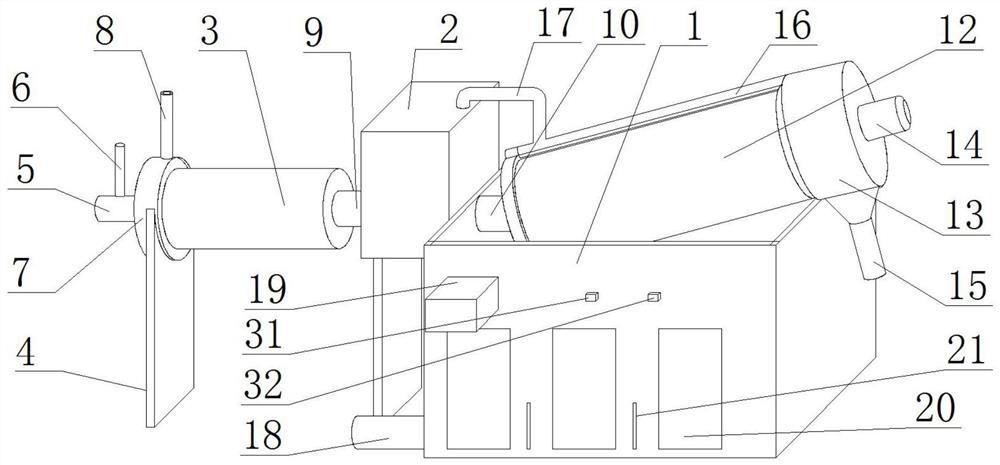

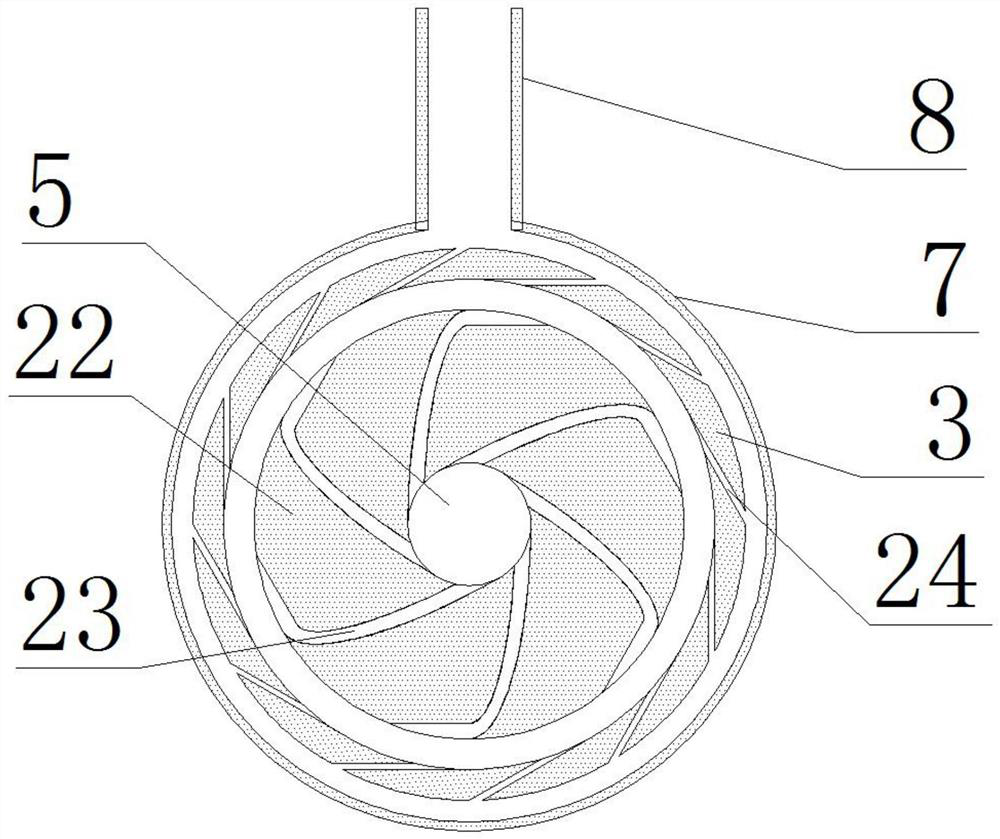

The invention provides an oil field fracturing flow-back fluid purification treatment device. The device comprises a water tank, a separation tank and sleeves; brackets are mounted at the bottoms of the sleeve and the separation box through bolts; a water pipe is welded to one side of the sleeve; an adding pipe is welded to the top of the water pipe. A clamping sleeve is welded to the outer side of the sleeve; an air pipe is welded to the top of the clamping sleeve. The sleeve is communicated with the separation box through a through pipe; an inlet pipe is welded on the other side of the separation box; according to the oil field fracturing flow-back fluid purification treatment device, residual free pollutants in water can be effectively adsorbed; purification quality of water is guaranteed, investment of chemicals and equipment is reduced; the fracturing flow-back fluid purification device has the advantages that strong oscillation is generated on fracturing flow-back fluid, chemicals can be quickly and uniformly mixed, the purification rate of the fracturing flow-back fluid is increased, the outer side of a filter cartridge can be back-blown, impurities in the filter cartridge can be blown off, the filter cartridge does not need to be replaced or peer-to-peer filter cartridge does not need to be cleaned, and the device is suitable for purification treatment of oilfield fracturing flow-back fluid.

Description

technical field [0001] The invention relates to the technical field of purification treatment of fracturing flowback fluid, in particular to an oilfield fracturing flowback fluid purification treatment device. Background technique [0002] Fracturing fluid is an important part of fracturing technology. Its main function is to create fractures and transport proppant along the open fractures. Therefore, the viscosity of the fluid is very important, and it can be flowed back quickly after operation with oily water. Further, the fracturing flowback fluid is formed, and with the continuous extension of oil exploitation time, the produced water continues to rise, and some even reach more than 90%, the sewage treatment volume increases rapidly, which brings huge pressure to environmental protection, so it is necessary to The fracturing flowback fluid can only be discharged outside after undergoing strict purification treatment. The patent application publication number is CN2019107...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/06C02F103/10

CPCC02F1/001C02F1/469C02F9/00C02F2103/10C02F2201/002C02F2201/007

Inventor 王雅东沈奎

Owner HUBEI PETROKH MACHINE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com