Iron ore special concrete and preparation method thereof

A technology for iron ore and concrete, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of concrete material wear, impact, ship contact, etc., to improve wear resistance and stability, The effect of strengthening the connection relationship and enhancing the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

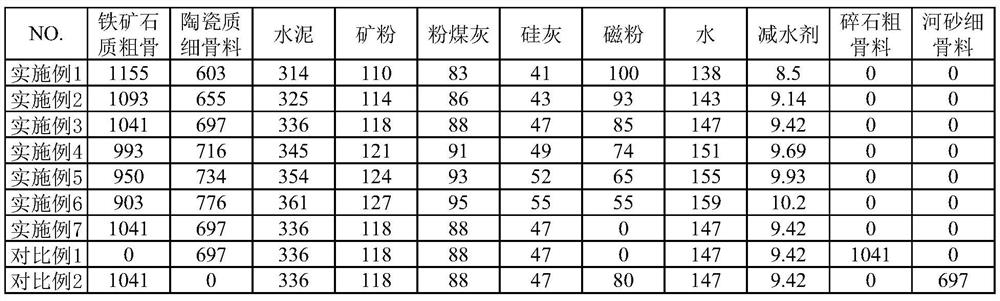

[0028] An iron ore-based special concrete disclosed in the present application includes the components shown in Table 1 in parts by weight. Among them, the iron ore coarse aggregate adopts continuous gradation, and the particle size range is 6-20mm; the ceramic fine aggregate adopts continuous gradation, and the particle size range is 1-5mm; the solid content of the water reducing agent used is 20%, and its water reduction rate is greater than 30%.

[0029] The preparation method of this kind of iron ore special concrete comprises the following steps:

[0030] S1: Put cement, fly ash, mineral powder, silica fume, magnetic powder, ceramic fine aggregate, part of water, and water reducing agent into the concrete mixer for mixing to obtain mortar;

[0031] S2: put the iron ore coarse aggregate and part of the water into the concrete mixer for mixing, and obtain the iron ore coarse aggregate after antirust treatment;

[0032] Wherein, the process of performing S1 specifically in...

Embodiment 2-7

[0036] The difference from Example 1 is that the parts by weight of each component included are different, and the specific values are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com